Control system and method for high-pressure roller mill closed circuit before magnetite mill

A high-pressure roller mill and closed-circuit control technology, which is applied in grain processing and other fields, can solve the problems that the operation level affects the control level of the high-pressure roller mill-closed-circuit screening process, increases the cost of manpower and labor, and reduces the health damage of post workers, so as to reduce manual manipulation. Links, improve the degree of automation, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

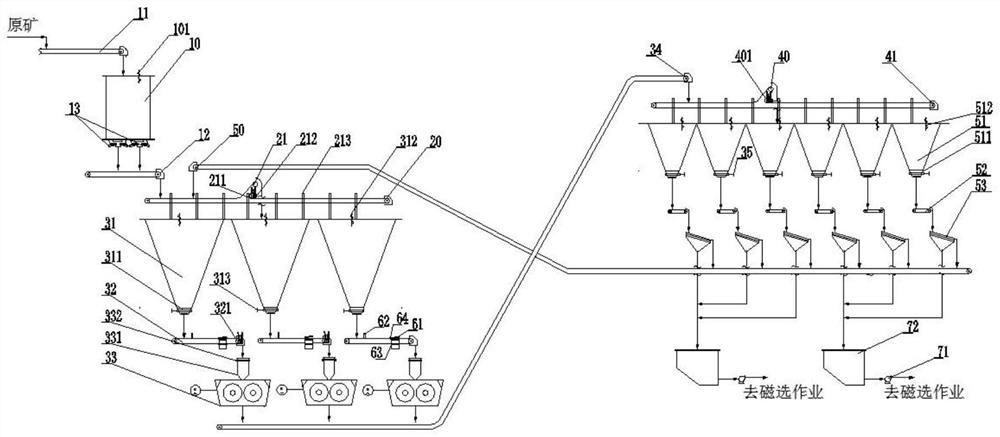

[0051] The high-pressure roller mill closed-circuit screening system is to feed the new material formed by the vibrating feeder and the returned material transported by the returning belt conveyor into the belt conveyor equipped with a mine leakage car; the mine leakage vehicle sends the material to into the high-pressure roller mill for crushing operations to form crushed materials; the crushed materials are sent to the belt conveyor equipped with a mine leakage car; Materials, the materials on the sieve pass through the return belt conveyor as return materials, and the materials under the sieve enter the magnetic separation process.

[0052] A closed-circuit control system and method for high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com