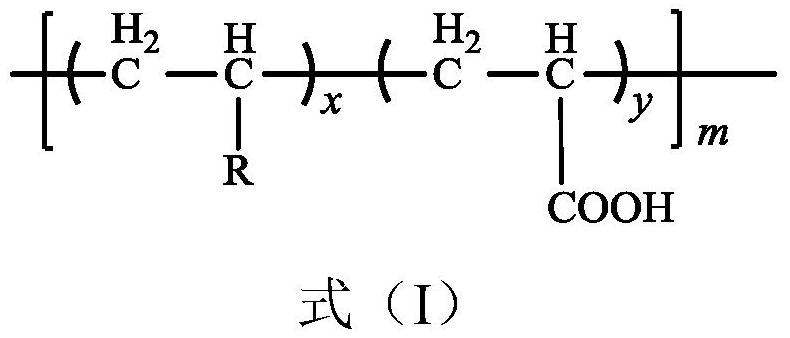

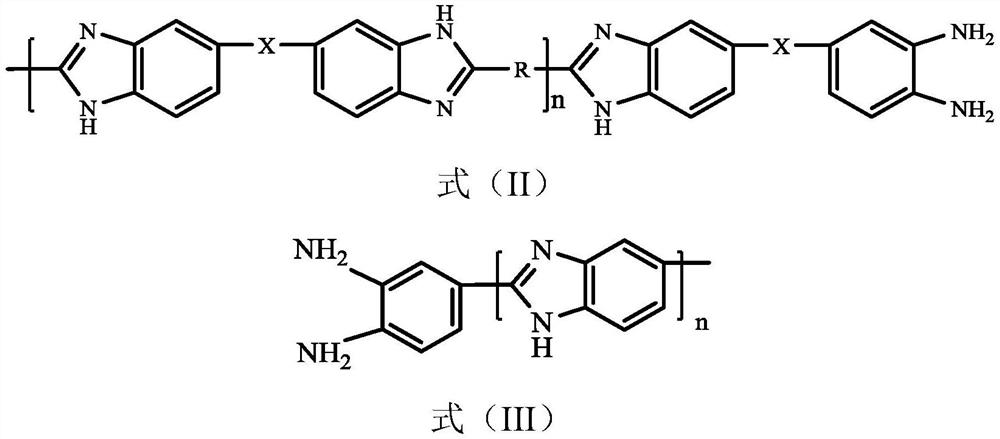

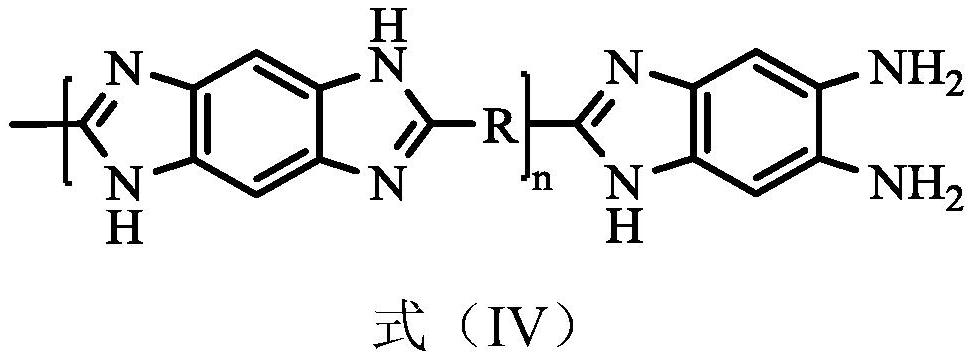

Graft copolymer coated silicon-based material and preparation method thereof

A graft copolymer, silicon-based material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of poor cycle performance and low first charge and discharge efficiency of lithium-ion batteries, and achieve the effect of inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0067] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0083] Preparation of PAA-g-mPBI coated silica material:

[0084] 0.003 parts by mass of mPBI (viscosity average molecular weight=250kDa) and 0.027 parts by mass of PAA (Mn=450,000) were dissolved in 1 part by mass of DMAc, and reacted at 150°C for 8h. Then add 99 parts by mass of DMAc and 100 parts by mass of irregular granular silicon oxide (D 50 10 μm) vigorously stirred for 4h. Then spray drying to obtain PAA 90 -g-mPBI 10 Coated silicon oxide negative electrode material (the total polymer mass (mPBI and PAA) is 0.03% of the silicon oxide mass).

[0085] Preparation of negative electrode sheet:

[0086] With the above-mentioned negative electrode material of 20 mass parts, the graphite of 74 mass parts, the conductive agent carbon black of 2.0 mass parts, the conductive agent carbon nanotube of 1.0 mass parts, the binding agent SBR of 2.5 mass parts, the carboxymethyl group of 0.5 mass parts Cellulose and 100 parts by mass of water are fully mixed to make negative ele...

Embodiment 2

[0092] Preparation of PAA-g-mPBI-coated silicon oxide material: the same as in Example 1, except that the total mass of the polymer is 0.06% of the mass of silicon oxide.

[0093] Negative electrode sheet, positive electrode sheet and battery preparation are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com