Hazardous chemical enterprise five-in-one safety management method based on artificial intelligence and Internet of Things

A security management and artificial intelligence technology, applied in office automation, image data processing, data processing applications, etc., can solve problems such as endangering the personal safety of staff, loss of staff and enterprises, damage to raw material storage equipment, etc., to ensure life and property Safety and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to further illustrate the technical means and efficacy of the present invention to achieve the object of the present invention, the following combined with the accompanying drawings and preferred embodiments, a five-part safety management method based on artificial intelligence in accordance with the present invention The specific embodiments, structures, features, and their effects are described in detail. In the following description, different "one embodiment" or "another embodiment" refers to not necessarily the same embodiment. In addition, specific features, structures, or features in one or more embodiments may be combined by any suitable form.

[0063] All techniques and scientific terms used herein are identical to those skilled in the art, unless otherwise defined.

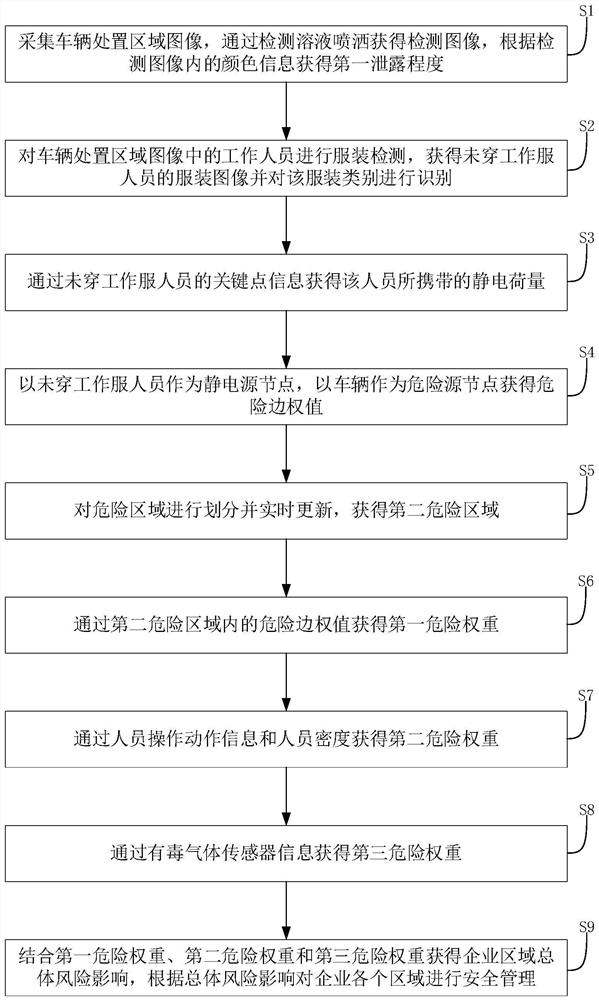

[0064] A specific scheme of a five-position safety management method based on artificial intelligence of hazardous enterprises will be described below with reference to the accompanying drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com