Deep true triaxial anisotropic coal rock gas seepage coupling test system and test method

An anisotropic and gas seepage technology, applied in the field of coal mines, can solve the problems of not considering the anisotropic change characteristics of the internal pore damage of coal samples, large errors in permeability data, etc., to achieve convenient coal sample permeability and reduce gas outburst risk, the effect of streamlining the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

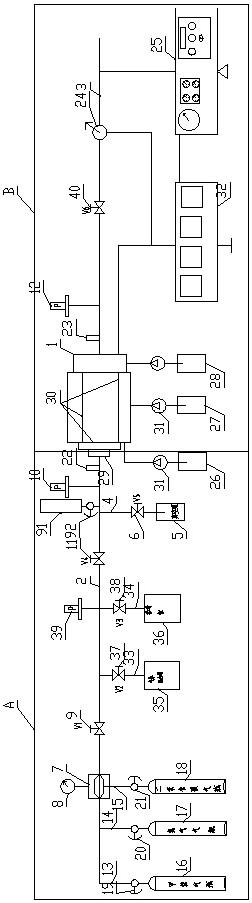

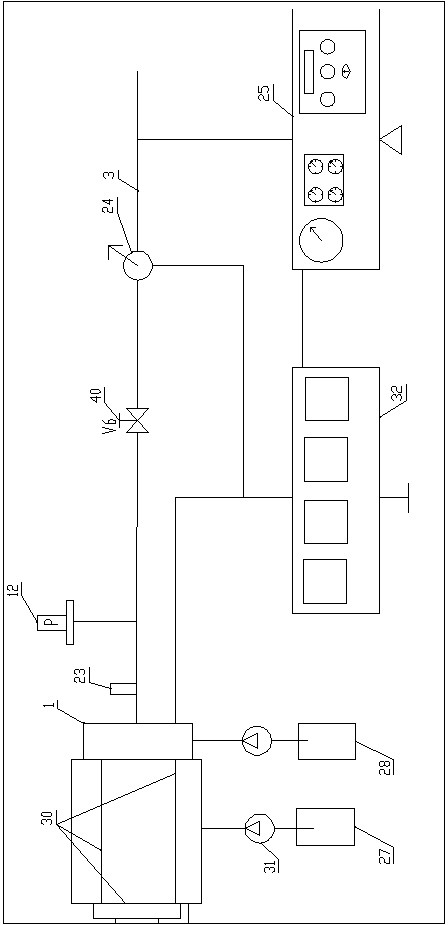

[0053] Such as Figure 1 to Figure 3 As shown, the deep true triaxial anisotropic coal-rock gas seepage coupling test system of the present invention includes a coal-rock holder 1, the coal-rock holder 1 has an air inlet and a gas outlet, and the inlet and outlet of the coal-rock holder 1 The gas port is connected to the intake manifold 2, the gas outlet is connected to the exhaust pipe 3, and the exhaust pipe is provided with a sixth valve 40;

[0054] The air intake main pipe 2 at the air inlet is connected with a vacuum pump 4, and the vacuum pump 4 is connected with a vacuum pump 5, and the fifth valve 6 is arranged on the vacuum pipe 4; the end of the air intake main pipe 2 is provided with a tee 7, three Air intake electronic pressure gauge 8 is provided on the passer 7; the direction of air flow is the downstream direction (that is, the three-way device 7 is the upstream end of the intake manifold 2, and the coal rock holder 1 is the downstream end of the intake manifol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com