Detection equipment for detecting stability of fabricated steel and use method of detection equipment

A testing equipment and stability technology, applied in the application of stable tension/pressure to test the strength of materials, preparation of samples for testing, measuring devices, etc. Accurate effect of error and advance distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

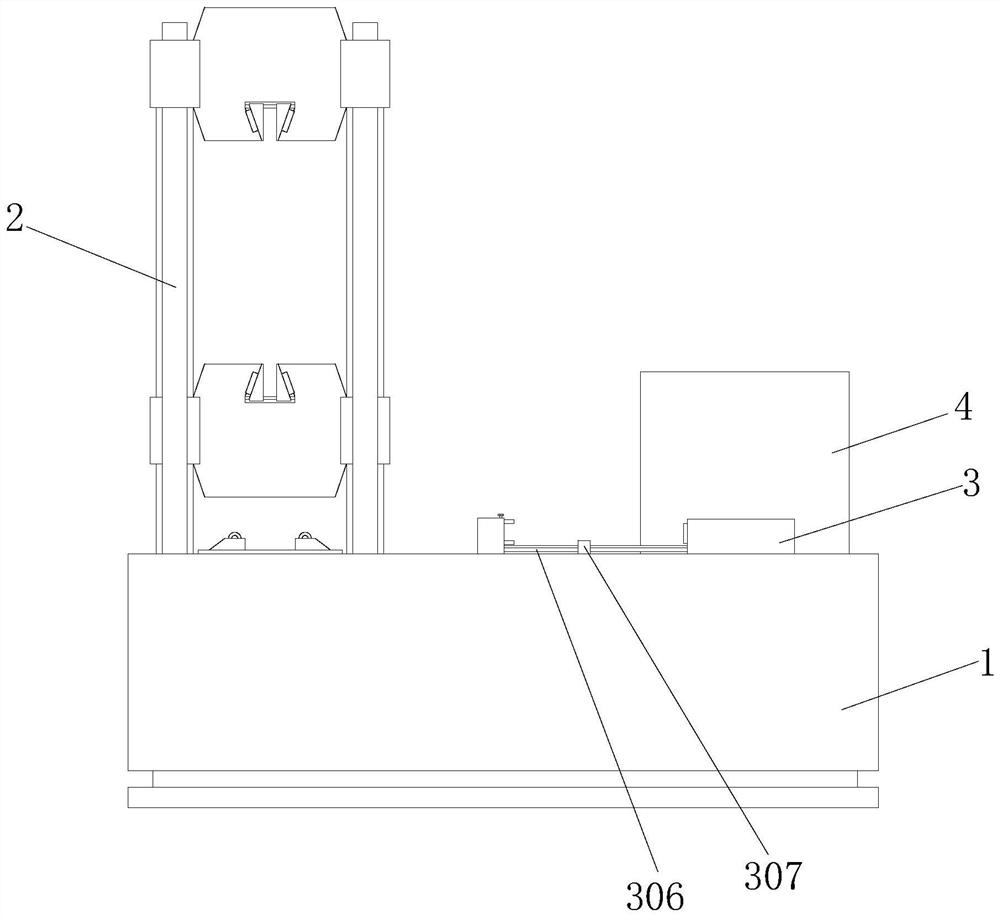

[0037] see Figure 1-7 , an embodiment provided by the present invention: a detection device for detecting the stability of assembled steel, comprising a workbench 1, a testing machine 2 is installed at one end of the top of the workbench 1, and the top of the workbench 1 is far away from the testing machine 2 An inspection device 3 is installed at one end, and a cutting device 4 is installed at one side of the top of the workbench 1 .

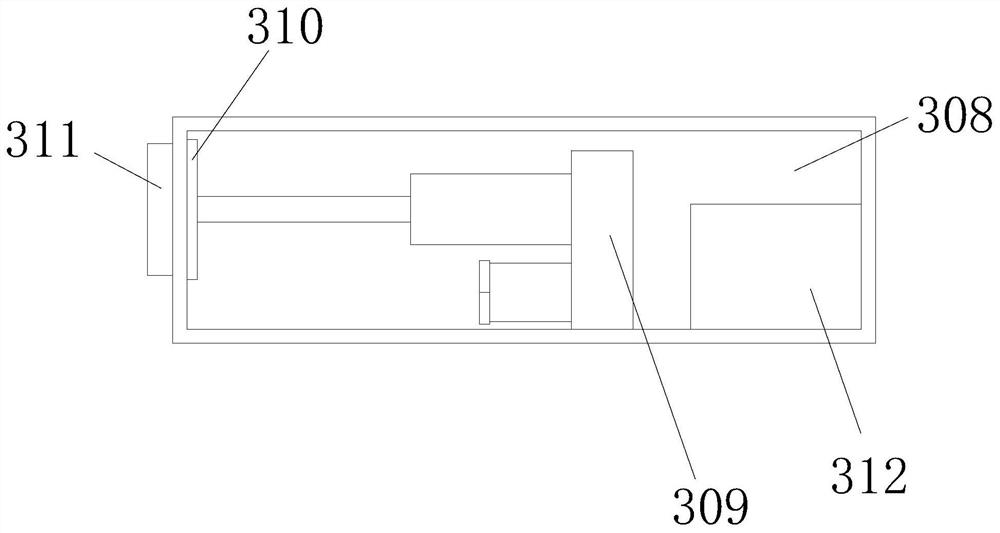

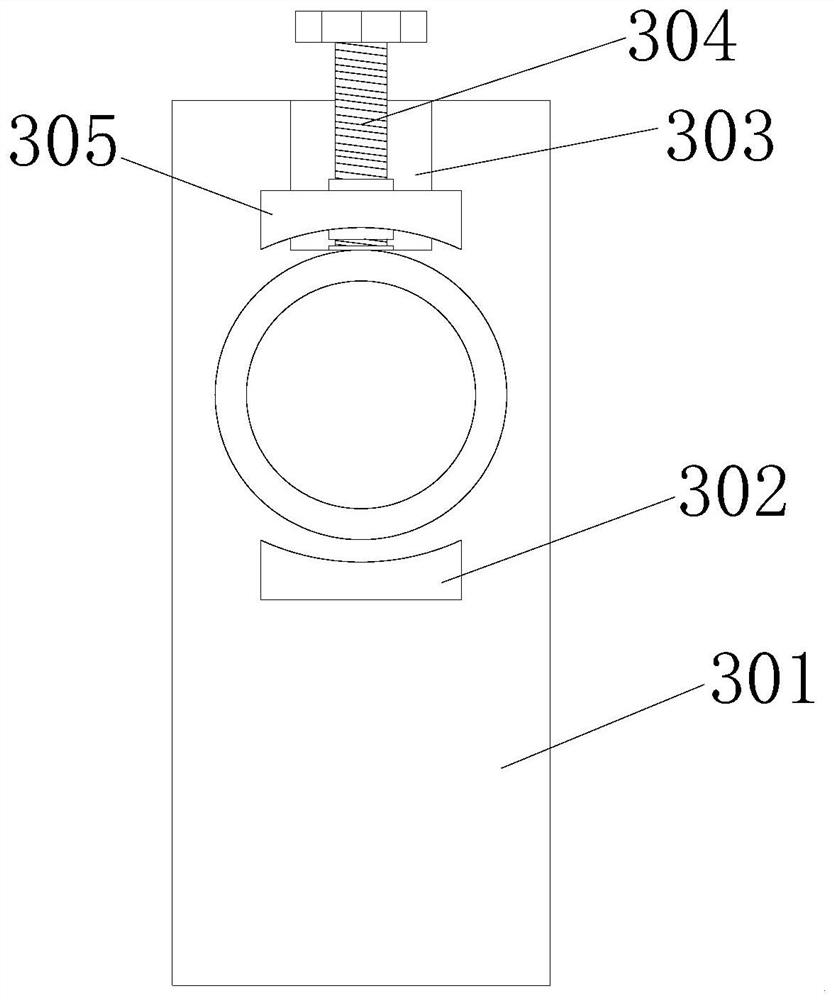

[0038] The inspection device 3 includes a mounting base 301, a placement plate 302 is installed on the bottom of the mounting base 301 away from the testing machine 2, a placement groove 303 is opened on the top of the mounting base 301 away from the testing machine 2, and a threaded rod is installed in the rotation of the placement groove 303. 304, a clamp block 305 is installed on the outer surface of the threaded rod 304, a slide rail 306 is installed on the bottom of the mounting seat 301 away from the end of the testing machine 2, a fixin...

Embodiment 2

[0049] see Figure 1-7 , an embodiment provided by the present invention: a detection device for detecting the stability of assembled steel, comprising a workbench 1, a testing machine 2 is installed at one end of the top of the workbench 1, and the top of the workbench 1 is far away from the testing machine 2 An inspection device 3 is installed at one end, and a cutting device 4 is installed at one side of the top of the workbench 1 .

[0050] The inspection device 3 includes a mounting base 301, a placement plate 302 is installed on the bottom of the mounting base 301 away from the testing machine 2, a placement groove 303 is opened on the top of the mounting base 301 away from the testing machine 2, and a threaded rod is installed in the rotation of the placement groove 303. 304, a clamp block 305 is installed on the outer surface of the threaded rod 304, a slide rail 306 is installed on the bottom of the mounting seat 301 away from the end of the testing machine 2, a fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com