A kind of construction method of shaped roof arc concrete flooding

A construction method and concrete technology, applied in the direction of roofing, roof drainage, roof covering, etc., can solve the problems of inconvenient material transportation, poor molding quality, and difficult protection of finished products, so as to ensure the quality of concrete, quality and greenness The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

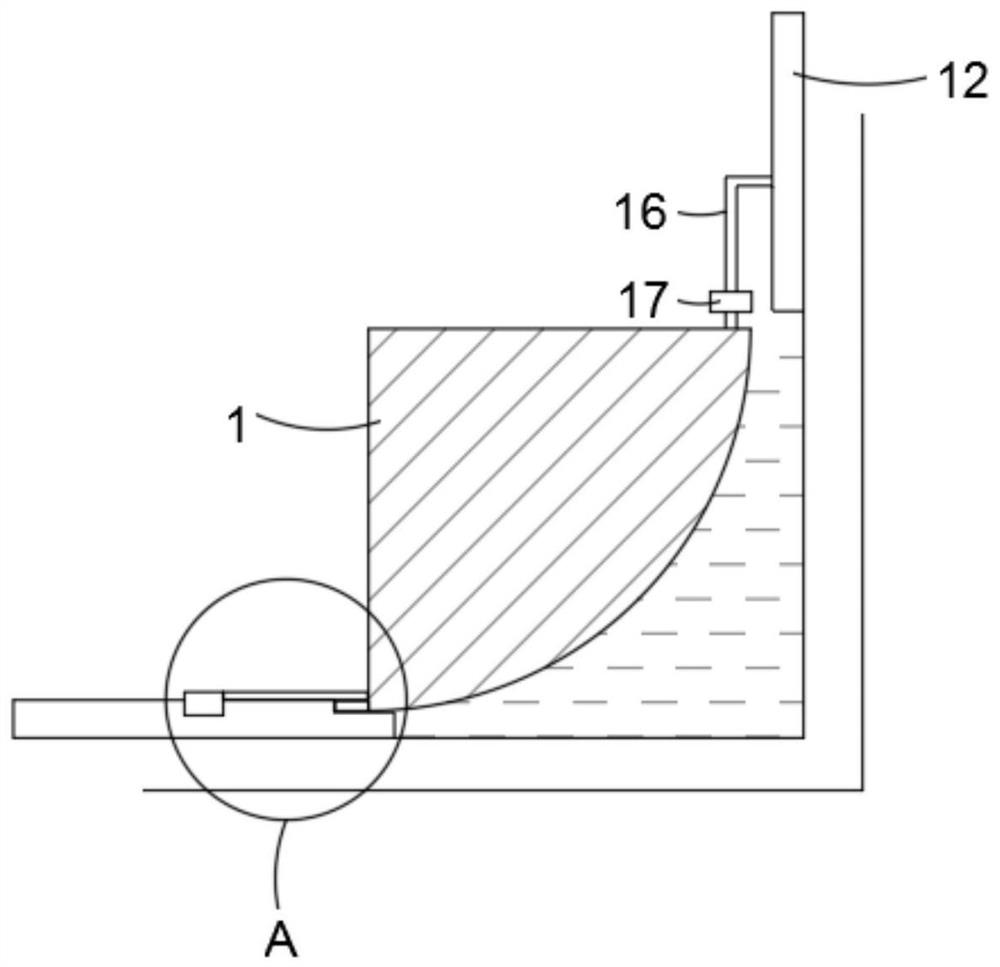

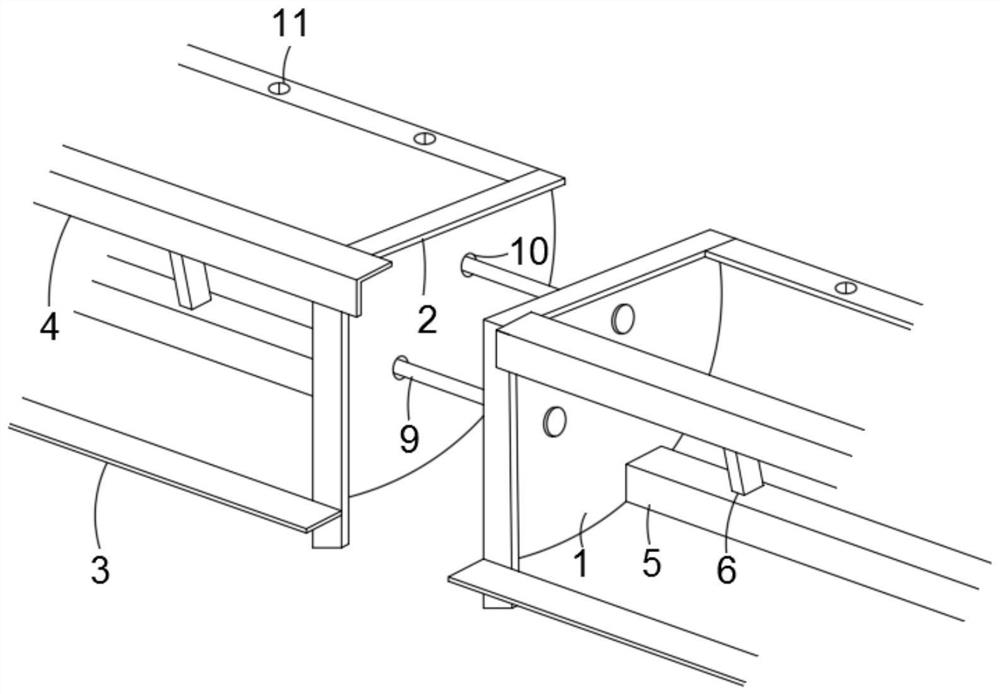

[0036] Reference Figure 1-3 , a stereotyped roof arc concrete flooding construction method, including the following steps:

[0037] S1: According to the size of the concrete circular arc design template 1, the formwork 1 is made of 1.5mm thick 304 stainless steel, and the length of the single section template 1 is 2m;

[0038] S2: Clean the roof and groove the surface of the roof and the inner side walls;

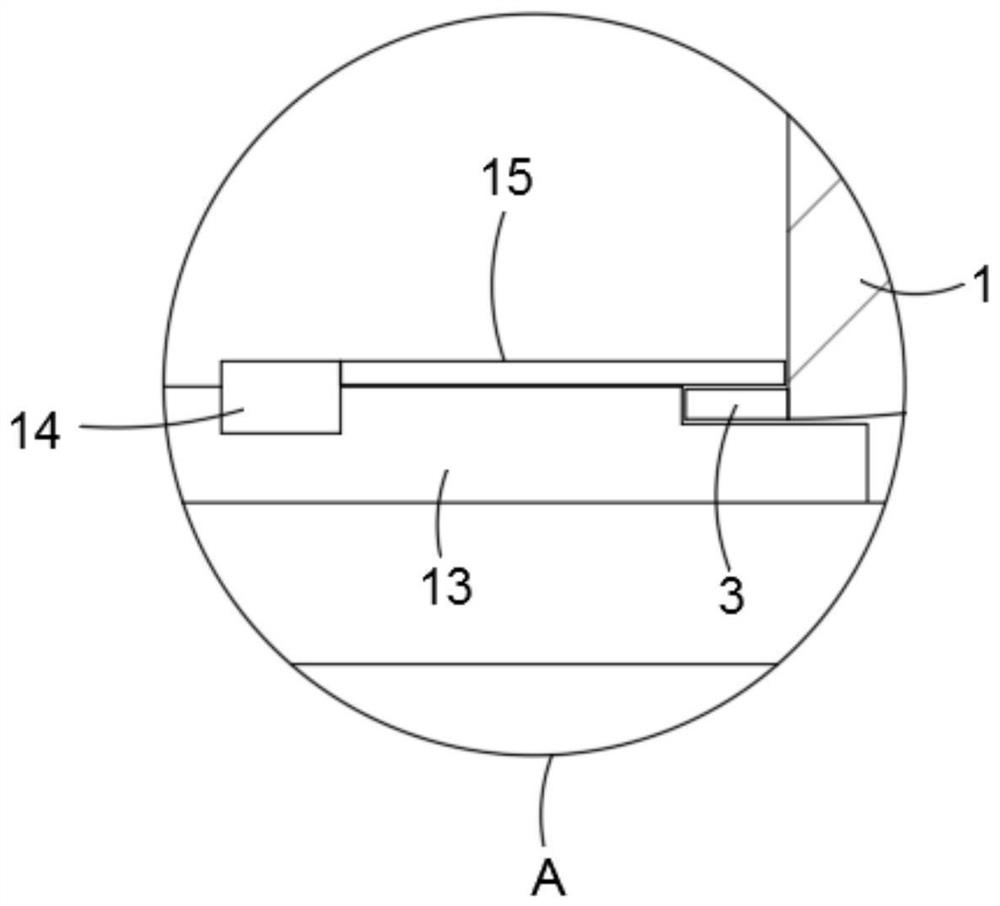

[0039] S3: fixed vertical plate 12 and horizontal plate 13 in two slots respectively;

[0040] S4: Make a connection between the multi-section template 1, after the connection is completed, placed between the vertical plate 12 and the horizontal plate 13, and fix it;

[0041] S5: Pour concrete paste between formwork 1 and the wall, vibrate and compact;

[0042] S6: After the concrete slurry is finalized, the formwork 1 is demolished;

[0043] Template 1 is a long and straight circular arc groove setting, the right angle side of template 1 is fixed with a right angle frame 2, both...

Embodiment 2

[0052] Reference Figure 4 , and the difference from example one is:

[0053] The connection mechanism includes a limit port 8 opened on the right angle frame 2, the adjacent two limit ports 8 are jointly inserted with a limit rod 7 of an inverted U-shape setting, when assembling the connection between the adjacent template 1, the two templates 1 are aligned, the limit rod 7 is inserted into the corresponding limit port 8, the connection between the two templates 1 can be completed, and the installation of this embodiment two is faster and more convenient than example one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com