Double pipe multifunctional grouting device and its construction method

A grouting device, double-tube type technology, applied in infrastructure engineering, wellbore/well components, construction, etc., can solve the problems of unfavorable cost and construction period, low construction efficiency, difficult to use for a long time, etc., so as to improve the service life And the use effect, the effect of improving the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

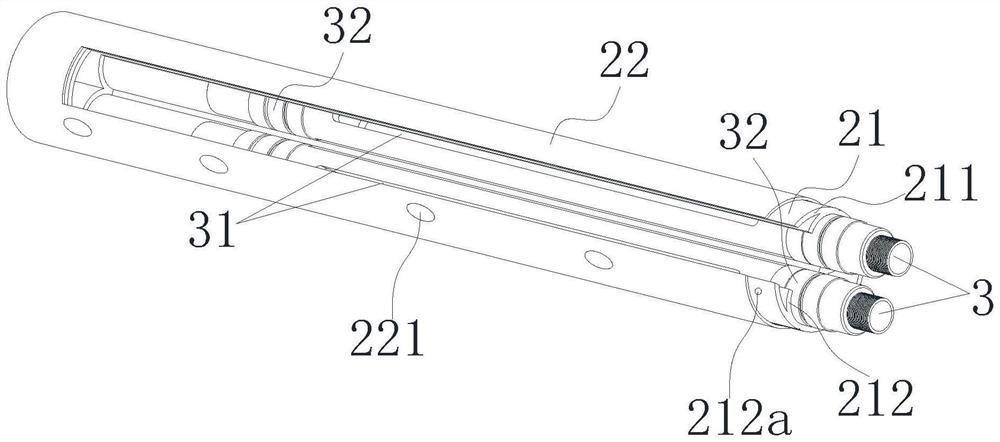

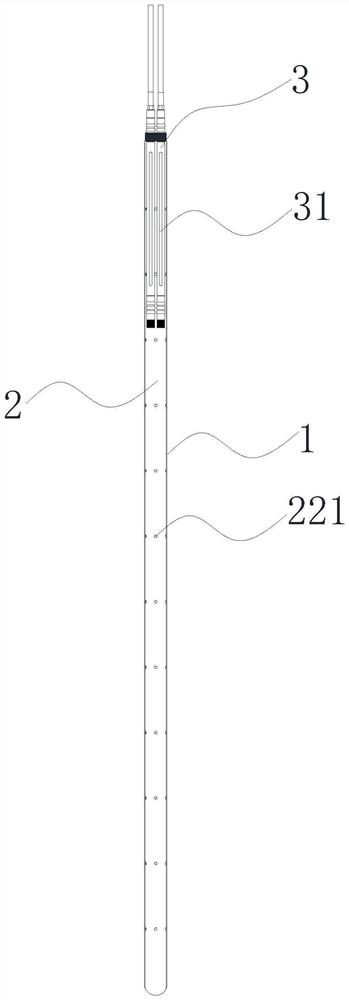

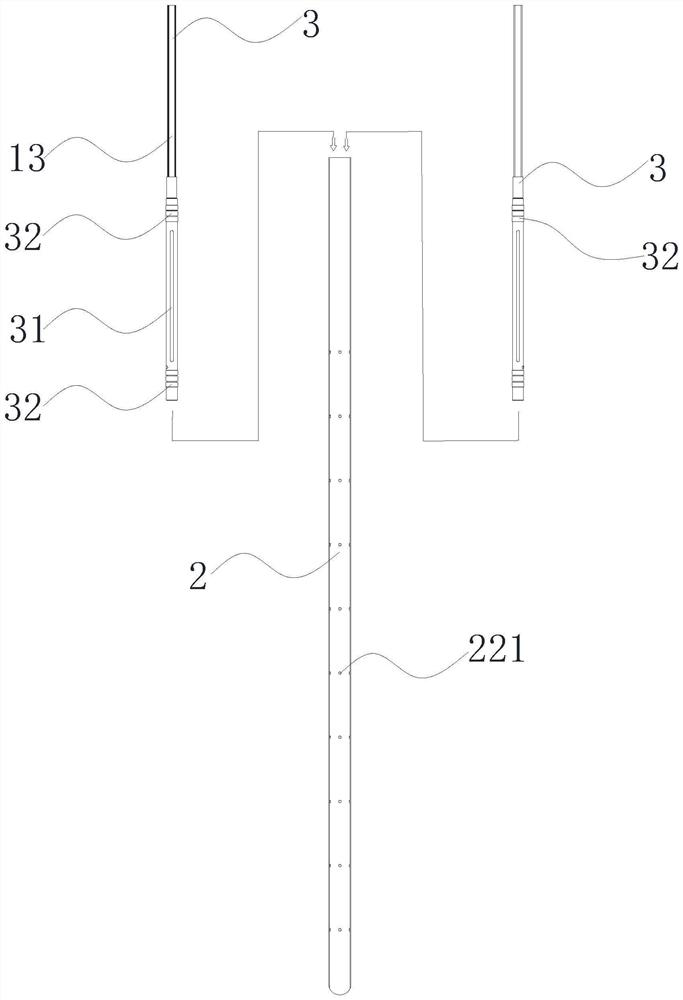

[0046] refer to Figure 1-Figure 6 Shown is the dual-pipe multifunctional grouting device of the present invention.

[0047] The device includes a grouting pipe 2 and a spraying pipe 3 inserted into the grouting pipe 2, the grouting pipe 2 includes an inner pipe 21 and an outer pipe 22; the outer pipe 22 is a deformable elastic pipe, The outer tube is provided with an outer slurry outlet 221, and the outer tube 221 is coated on the outside of the inner tube 21; the inner tube 21 includes an inner tube wall 211 attached to the inner side of the outer tube. At least two grouting pipes 212 are formed inside the pipe wall 211, and the side walls of the grouting pipes 212 are provided with inner grouting outlets 212a; the grouting pipe 3 is matched with the grouting pipes 212 and inserted into the grouting pipes In the slurry pipeline, the spray pipe 3 is provided with a material outlet 31, and the material outlet 31 communicates with the inner slurry outlet 212a. The elastic out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com