A powder feeder with adjustable friction force of powder disc

A friction force and powder feeder technology, applied in metal material coating process, coating and other directions, can solve the problems of powder pan stop, excessive friction force, etc., to reduce friction force, reduce reaction pressure, improve The effect of ease of debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

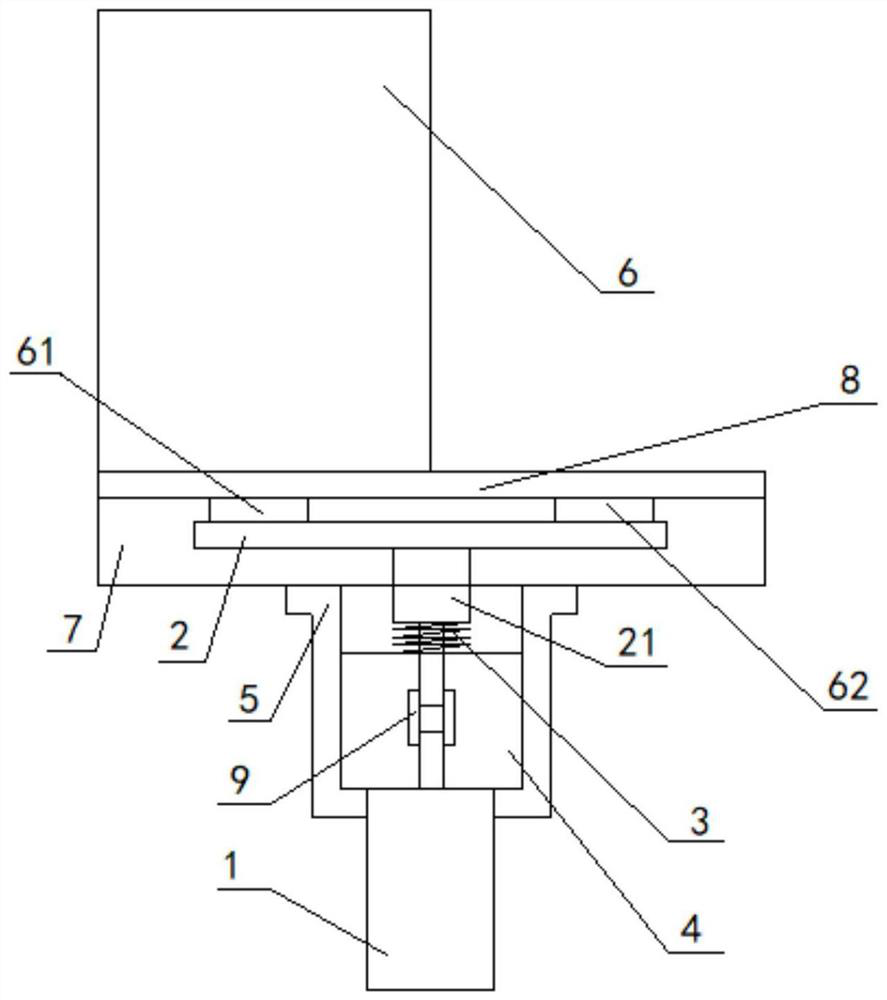

[0038] figure 1 It is a schematic structural diagram of a powder feeder with adjustable powder pan friction according to an embodiment of the present invention, figure 2 for figure 1 Schematic diagram of the structure of the middle lifting mechanism. likefigure 1 and figure 2 As shown, the present invention provides a powder feeder with adjustable powder pan friction, including a motor 1, a powder pan 2, a spring 3, a lifting mechanism 4, a mounting bracket 5, a powder storage bin 6, a powder feeding bin 7, and a mounting plate 8;

[0039] The powder storage bin 6 is a closed container, and a powder drop port 61 is provided below the powder storage bin 6, and the powder in the powder storage bin 6 falls into the groove of the powder tray 2 through the powder drop port 61;

[0040] The powder pan 2 is fixedly installed on the T-shaped shaft 21, and the powder pan 2 is placed in the powder feeding bin 7. The powder feeding bin 7 and the mounting plate 8 form a closed space,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com