Water-based cutting lubricating fluid with ultralow friction coefficient

A technology of ultra-low friction and lubricating fluid, applied in lubricating compositions, petroleum industry, etc., can solve problems such as complex preparation process, environmental pollution, and many components, and achieve simple preparation method, ensure production safety, and smooth contact surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

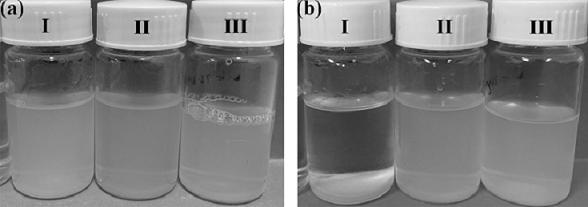

[0036] Example 1 An ultra-low friction coefficient water-based cutting lubricating fluid, which is prepared by mixing the following components uniformly in parts by weight: 50 parts of ethylene glycol, 50 parts of deionized water, dibutyl phosphate 1.5 parts of ester·dodecyldimethylamine ionic liquid, 0.0065 parts of HO-BNNs.

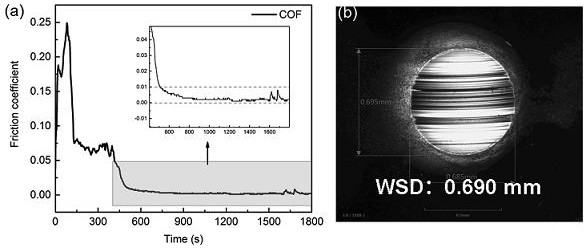

[0037] The tribological properties of the prepared cutting lubricants were tested by a four-ball friction tester (MS-10 A). The steel balls used in the test are φ = 12.7 mm GCr15 bearing steel balls. The test conditions are the coefficient of friction (COF) when the load is 196 N, the speed is 1200 r / min, and the long grinding is 30 minutes at room temperature. Use XDS-0745D optical microscope and MicroXAM 3D non-contact surface tester to test the wear spot diameter on the surface of the steel ball.

[0038] The result is as figure 2 As shown, the lubrication system enters into a super-slip state (friction coefficient less than 0.01) after a runni...

Embodiment 2

[0039]Example 2 A water-based cutting lubricating fluid with an ultra-low coefficient of friction, which is the same as that in Example 1.

[0040] The tribological properties of the prepared cutting lubricants were tested by a four-ball friction tester (MS-10 A). The steel balls used in the test are φ = 12.7 mm GCr15 bearing steel balls. The test conditions are the coefficient of friction (COF) when the load is 196 N, the speed is 1450 r / min, and the long grinding is 30 minutes at room temperature. Use XDS-0745D optical microscope and MicroXAM 3D non-contact surface tester to test the wear spot diameter on the surface of the steel ball.

[0041] The result is as image 3 As shown, compared with Example 1, when the speed is increased to 1450 r / min, the lubrication system enters the super-slip state (friction coefficient is less than 0.01) after a running-in period of about 500 s, and the friction coefficient is more stable, and The ultra-slip state was maintained until th...

Embodiment 3

[0042] Example 3 An ultra-low friction coefficient water-based cutting lubricating fluid, which is prepared by mixing the following components uniformly in parts by weight: 50 parts of 1,3-propanediol, 50 parts of deionized water, phosphoric acid 1.5 parts of dibutyl ester·dodecyldimethylamine ionic liquid, 0.0065 parts of HO-BNNs.

[0043] The tribological performance evaluation test conditions of the cutting lubricating fluid are the same as in Example 1.

[0044] The result is as Figure 4 As shown, compared with Example 1, replacing ethylene glycol with 1,3-propanediol, the lubrication system enters a super-slip state (friction coefficient is less than 0.01) after a running-in period of about 100 s, and remains super-slip State Until the end of the experiment, the wear spot diameter (WSD) was 0.6481mm. It shows that the lubricating performance of this system is good. In addition, the diameter of the wear scar becomes smaller and the surface is smooth and flat. It is suit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com