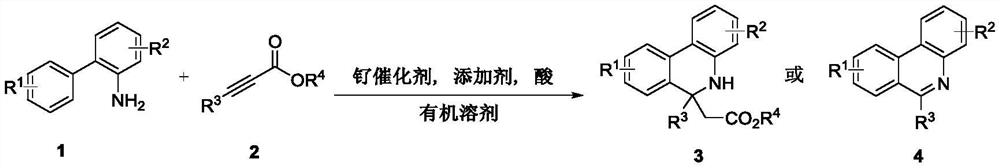

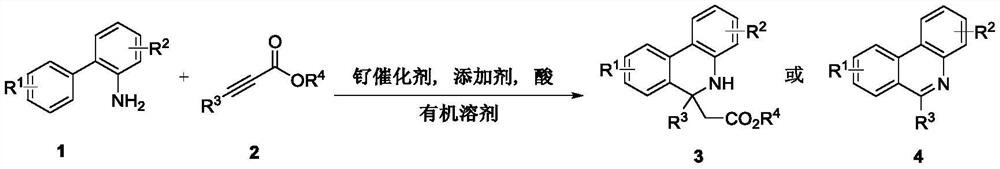

Method for selectively synthesizing dihydrophenanthridine or phenanthridine compound

A technique for dihydrophenanthridine and compounds, which is applied in the field of selective synthesis of dihydrophenanthridine or phenanthridine compounds, can solve problems such as lack of universal applicability, single product structure, and difficult acquisition of raw materials, and achieve cheap raw materials, The synthesis process is simple and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

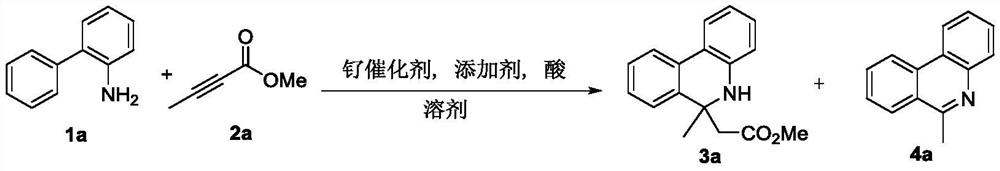

Embodiment 1

[0021]

[0022] Add 1a (50.8mg, 0.3mmol), 2a (44.1mg, 0.45mmol), solvent (2mL), ruthenium catalyst (0.015mmol), additive (0.06mmol), acid (0.6mmol) and Molecular sieves (50mg), under the protection of argon, seal the pressure tube, and stir the reaction at a certain temperature. After the reaction is over, use saturated NaHCO 3 The solution was quenched, filtered with suction, extracted with ethyl acetate (10mL×3), the organic phases were combined and washed with water and saturated sodium chloride solution successively, anhydrous Na 2 SO 4 Dried, spin-dried, and separated by silica gel column (petroleum ether / ethyl acetate=20 / 1 to petroleum ether / ethyl acetate=10 / 1) to obtain product 3a and / or 4a.

[0023] A series of reaction results are obtained by changing reaction conditions such as catalyst, additive, acid type, solvent, temperature and the equivalent ratio between reactants, as shown in Table 1.

[0024] Synthesis of 3a and 4a under different reaction conditions ...

Embodiment 2

[0028] Add 1a (50.8mg, 0.3mmol), 2a (44.1mg, 0.45mmol), tetrahydrofuran (2mL), dichlorobis(4-methylisopropylphenyl) ruthenium (II) to a 15mL pressure-resistant tube sequentially ( [Ru(p-cymene)Cl 2 ] 2 ,9.2mg, 0.015mmol), silver trifluoromethanesulfonate (15.4mg, 0.06mmol), acetic acid (34.3μL, 0.6mmol) and MS (50mg), and then the pressure tube was sealed under the protection of argon, and placed in a 60°C oil bath to stir for 24 hours. After the reaction is over, use saturated NaHCO 3 The solution was quenched, suction filtered, extracted with ethyl acetate (10mL × 3), the organic phases were combined and washed with water and saturated sodium chloride solution successively, anhydrous Na 2 SO 4 Drying, spin-drying, and silica gel column separation (petroleum ether / ethyl acetate=20 / 1) gave white solid product 3a (50.5 mg, 63%). The characterization data of this compound are: 1 H NMR (CDCl 3 ,400MHz):δ7.73(d,J=8.0Hz,1H),7.68(d,J=7.6Hz,1H),7.32-7.23(m,3H),7.12(t,J=7.2Hz,...

Embodiment 3

[0030] According to the method and steps of Example 2, by changing reactants 1 and 2, multiple dihydrophenanthridine compounds 3 were synthesized, and the specific results are shown in Table 2.

[0031] The synthesis of various dihydrophenanthridine compounds 3 of table 2 a,b

[0032]

[0033] a Reaction conditions: 1(0.3mmol), 2(0.45mmol), [Ru(p-cymene)Cl 2 ] 2 (0.015mmol), AgOTf (0.06mmol), AcOH (0.6mmol), MS (50mg), THF (2mL), argon atmosphere, 60°C, 24 h.b Separation yield.

[0034] Representative product characterization data are as follows:

[0035] Methyl 2-(8-methoxy-6-methyl-5,6-dihydrophenanthridin-6-yl)acetate(3d)

[0036] Yellowish solid (58.0mg, 65%). 1 H NMR (CDCl 3 ,400MHz): δ7.74(d,J=8.4Hz,1H),7.67(dd,J 1 =7.6Hz,J 2 =0.8Hz,1H),7.15(td,J 1 =7.6Hz,J 2 =1.2Hz,1H), 6.94(dd,J 1 =8.4 Hz,J 2 =2.4 Hz,1H),6.90(td,J 1 =7.6 Hz,J 2 =0.8 Hz, 1H), 6.86(d, J=2.4 Hz, 1H), 6.78(dd, J 1 =8.0 Hz,J 2 =0.8 Hz, 1H), 4.95(s, 1H), 3.89(s, 3H), 3.70(s, 3H), 2.90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com