Optical lens polishing device and polishing process

A technology for optical lenses and polishing devices, which is applied to grinding/polishing safety devices, optics, optical components, etc., can solve the problems of reducing the surface shape change of optical lenses, and achieves the improvement of polishing effect, reducing surface shape change, and weakening beating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

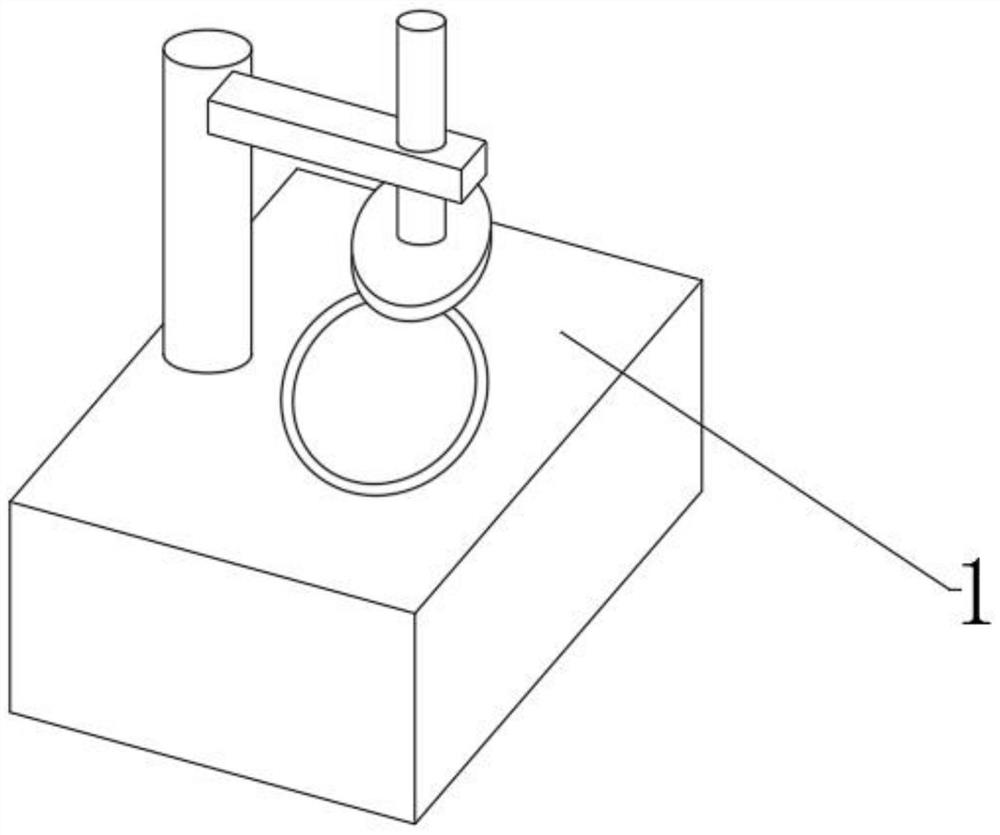

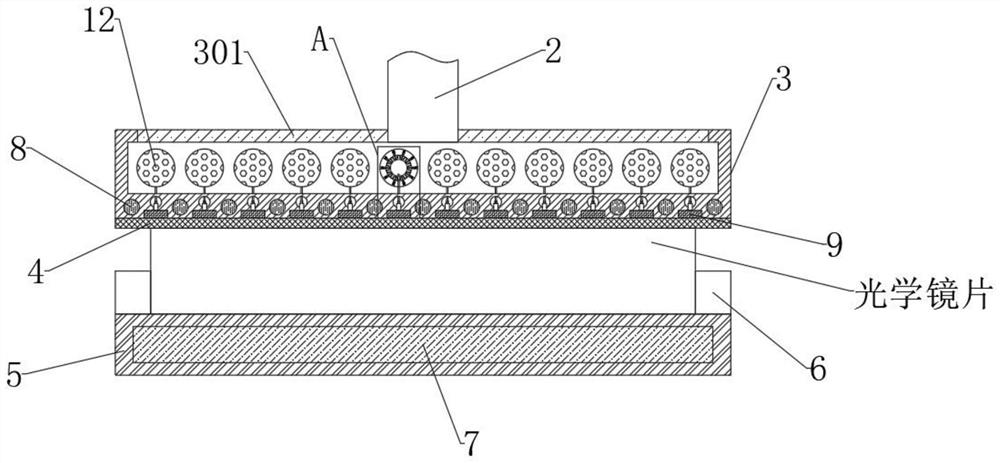

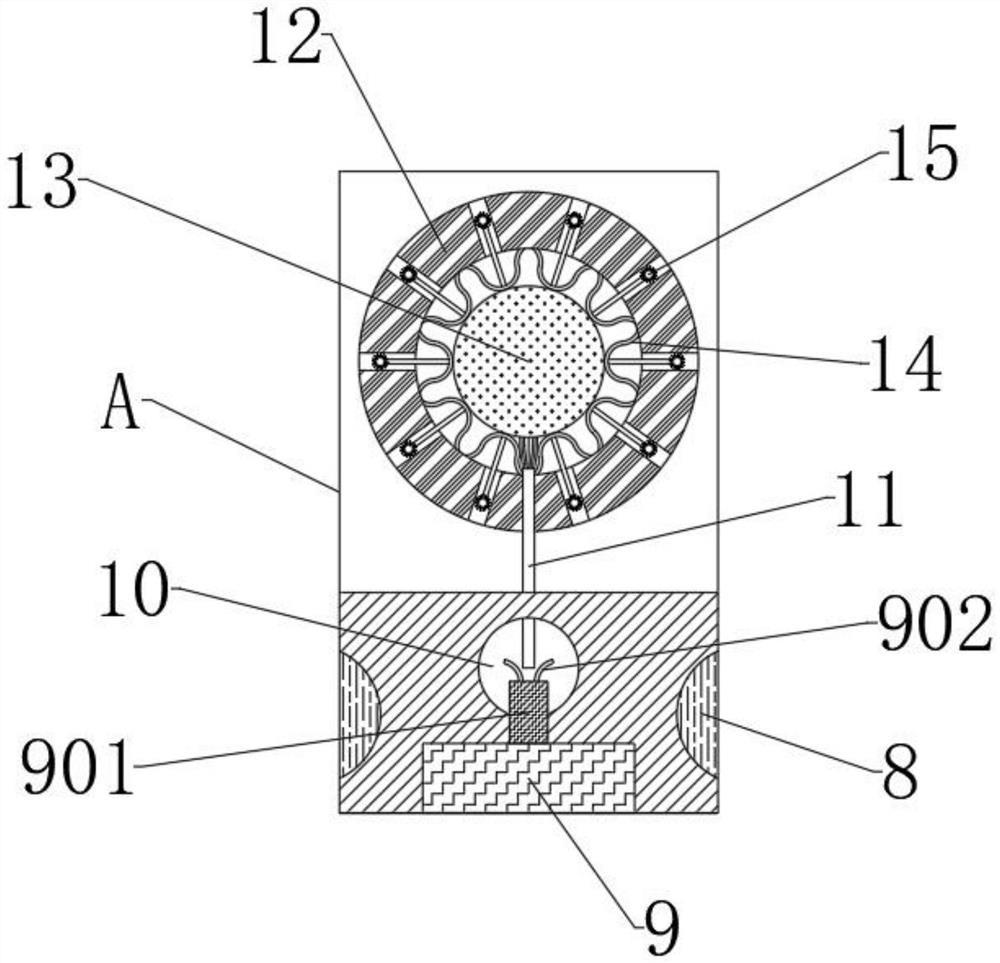

[0044] see Figure 1-6 , an optical lens polishing device and a polishing process, including a polishing machine body 1, please refer to figure 1 The polishing machine body 1 includes a telescopic column 2, a polishing disc 3 is installed at the lower end of the telescopic column 2, and an observation window 301 is fixedly inlaid on the side wall of the upper end of the polishing disc 3, and the observation window 301 is made of a transparent material, which is to facilitate the work. The personnel sees the color change of the color marking ball 12, and the lower end of the polishing disc 3 is bonded with a polishing skin 4, the polishing machine body 1 includes a rotating base 5, and two symmetrically arranged pneumatic clamps 6 are installed on the upper end of the rotating base 5, and An optical lens is clamped between two pneumatic clamps 6, and an electromagnet 7 is installed in the middle of the rotating base 5 (its specific model can be selected according to actual need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com