A light curing filter element and preparation method thereof

A filter element and light-curing technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of difficult control of dimensional accuracy, complicated tooling for stacking aluminum partitions, labor-intensive, etc., to reduce health effects, The effect of prolonging the service life of equipment and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

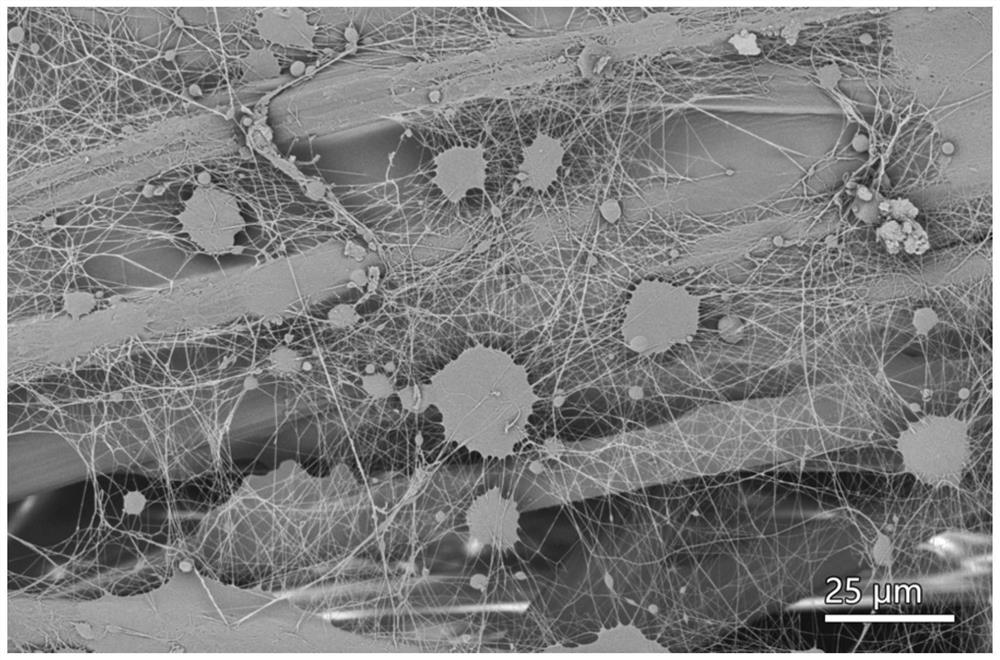

[0060] The invention provides a light-curing filter element, which includes an adsorption material, a coating material, a light-curing glue and an auxiliary agent. The inside of the coating material is filled with the absorption material, and the outside of the coating material is placed with light at a set interval. Curing glue; or use non-impregnated and impregnated light-curing glue to mix and spin the covering material; or light-curing glue is filled between the adsorption materials; or light-curing glue penetrates the adsorption material and connects with the surface of the covering material; Or the light-curing glue is pasted on the side of the coating material; or the above two or more combinations; the auxiliary agent is added to the adsorption material or coated on the outside of the light-curing glue. figure 2 It is the SEM picture of the cured glue on the side of the light-cured filter element of the present invention.

[0061] Wherein, the distance between the pho...

Embodiment 2

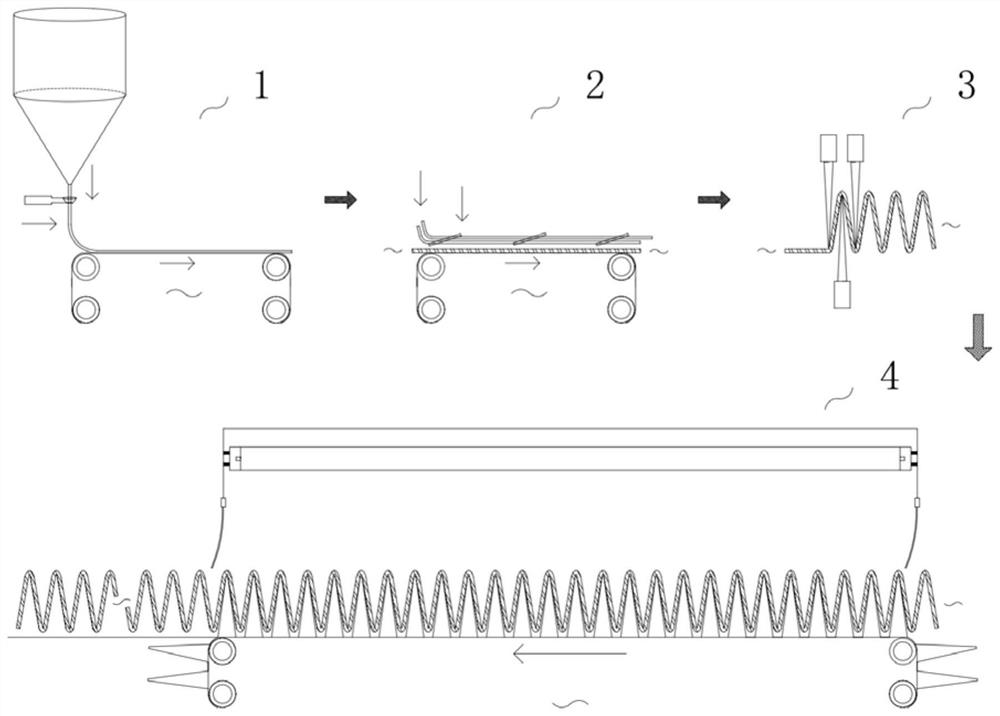

[0087] Such as figure 1 As shown, the present invention also provides a method for manufacturing a light-cured filter element, including: putting light-curable glue into the adsorption material, coating material, and auxiliary agent; Die to obtain the desired photocurable filter element.

[0088] The process of placing the light-curing glue is as follows: extrude the tank and inject the light-curing glue into the light-transmitting film of the auxiliary agent, and seal the film in sections to form a paste (such as figure 1 In device 1), the paddles are placed in the adsorption material and the coating material in a set arrangement (such as figure 1 device 2); or the light-curing adhesive is directly placed in the adsorption material, coating material, and auxiliary agent in the form of a 3-15 Pa·s high-viscosity liquid.

[0089] Wherein, the extrusion flow rate is 2-200 mm / s, preferably, the flow rate is 10-40 mm / s. Select the appropriate flow rate according to the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com