Method for converting electrical energy into thermal energy and electrical heating device using same

A technology of electric energy conversion and thermal energy, applied in coil devices, induction heating, induction heating control, etc., can solve problems such as increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

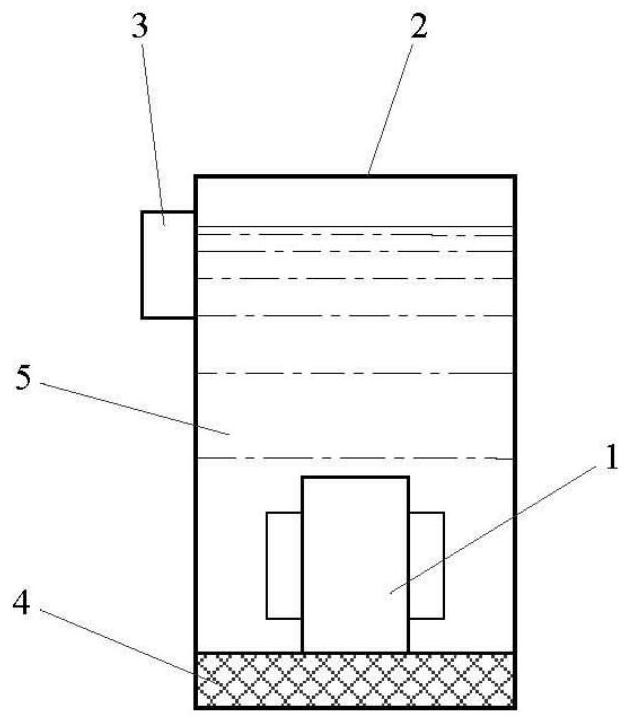

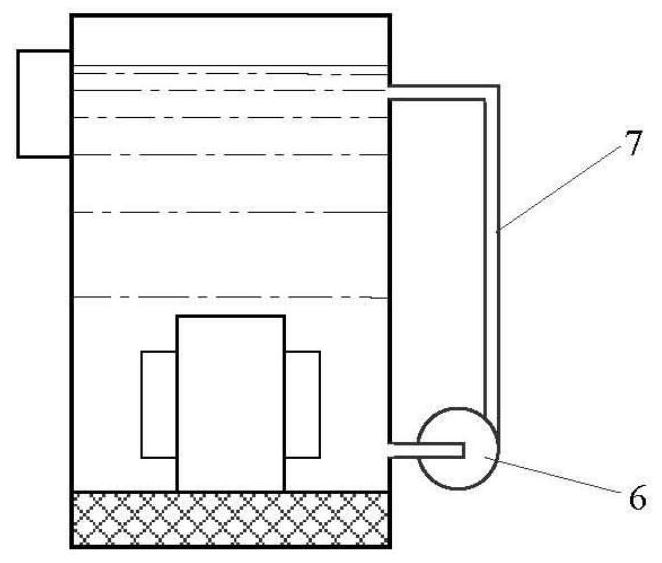

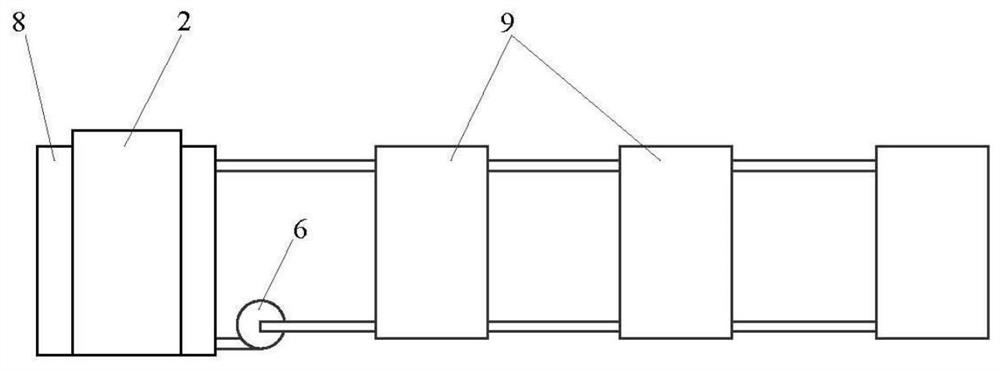

[0027] Throttle valve 1 is used with unpressurized windings and cores to improve the ability to impregnate them with liquid heat carrier 5 . After dipping, the leakage current through the insulator is reduced, the electrical breakdown resistance is increased, and the heat transfer from the heating element to the heat carrier 5 is maximized. Capacitor 10 may be located outside or inside tank 2 . In the second case, the heat from the capacitor is also transferred to the heat carrier 5 . As the heat carrier 5, any liquid substance such as transformer oil, glycerin, paraffin (liquid), etc. that does not damage the insulation of parts and materials located inside the storage tank 2 can be used. The spacer 4 is intended to dampen the effects of vibrations produced by the core of the throttle valve 1 .

[0028] When the switch 13 is closed, the electrical part of the heater 15 immediately goes into ferroresonant mode. It provides all circuit details and correct selection of AC pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com