Weldment contour detection method

A contour detection and weldment technology, applied in computer parts, image analysis, image enhancement and other directions, can solve the problems of uneven illumination, weld edge detection interference, small gray value gradient, etc., to improve image contrast, enhance Dynamic range, simple operation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

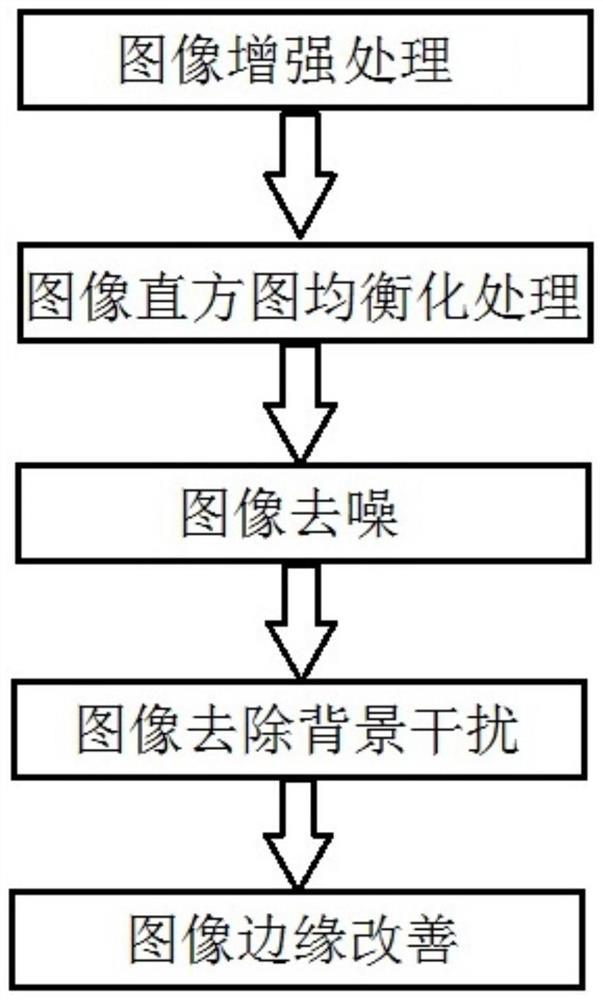

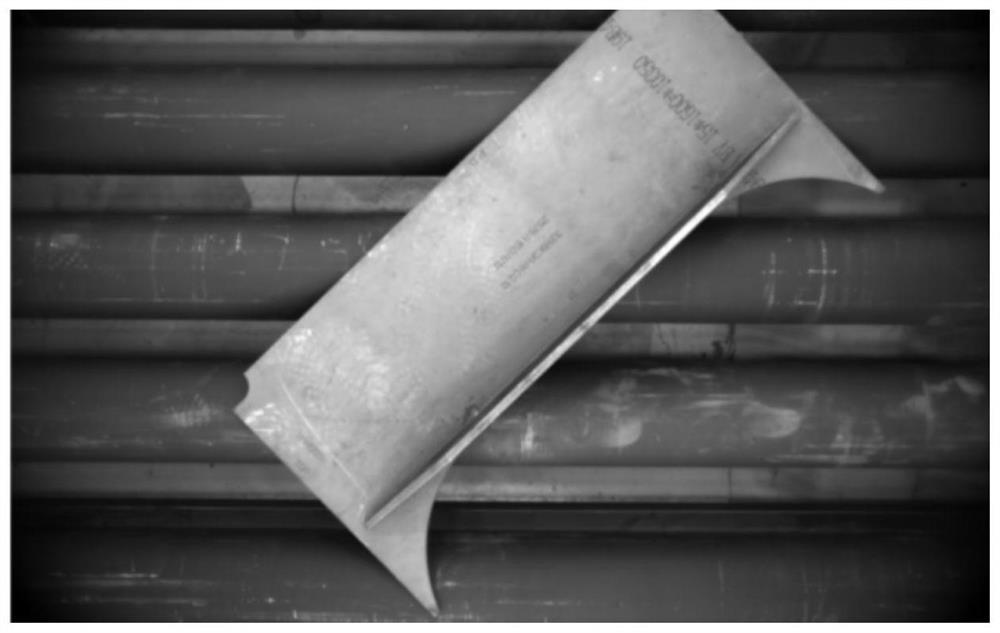

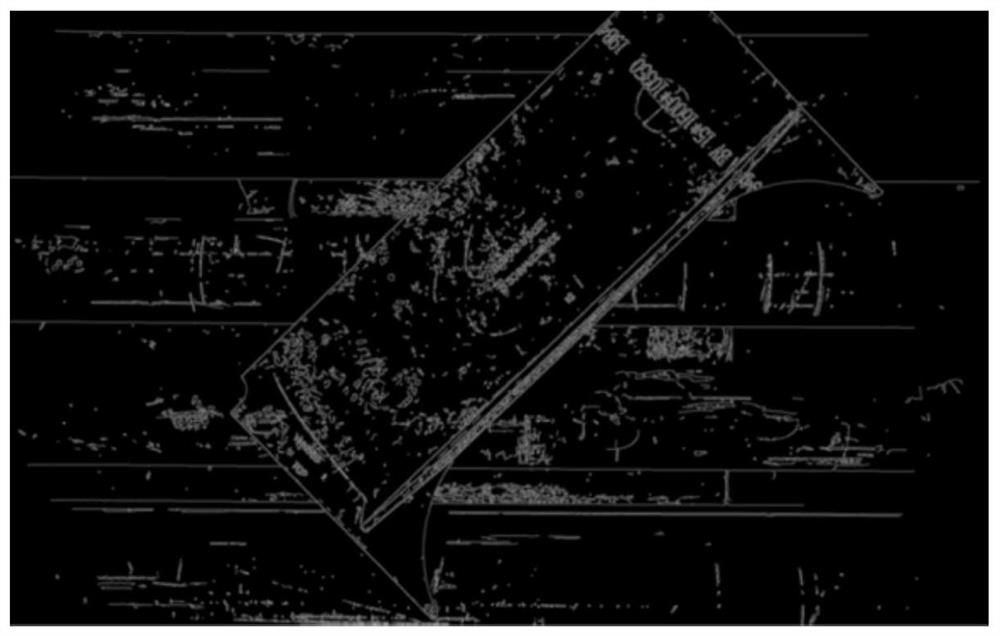

[0047] Such as figure 1 As shown, the weldment contour detection method of the present invention. Firstly, the image is enhanced, in order to solve the noise interference problem existing in the edge detection of the weldment image by the Canny edge detection algorithm, such as figure 2 and image 3 As shown, the present invention uses an image enhancement method to preprocess the collected weldment images to improve the accuracy of edge detection. The purpose of image enhancement is to perform a series of processing on the image to make it more suitable for some specific scenes than the original image. There are two main types of image enhancement method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com