Optical fiber mode field adapter with cladding power stripping function and preparation method thereof

A mode field adapter and cladding technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of damage to subsequent devices, damage to lasers, device influence, etc., and achieve the effect of reducing difficulty, reducing operating temperature, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

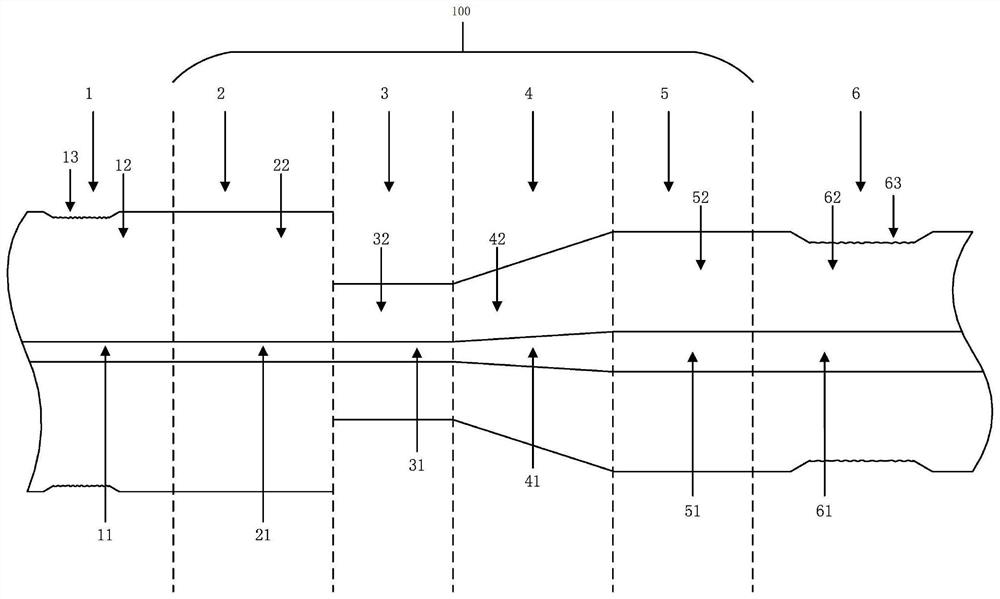

[0051] The present invention also provides a method for preparing an optical fiber mode field adapter with cladding power stripping function, comprising the following steps:

[0052] In the first step, the input optical fiber 2 and the output optical fiber 5 are prepared, wherein the core diameter of the output optical fiber 5 is greater than the core diameter of the input optical fiber 2;

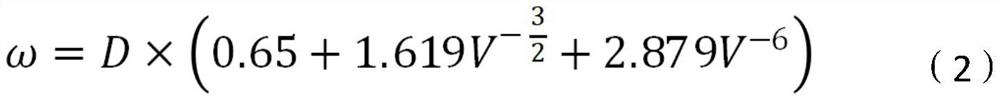

[0053] In the second step, according to the parameter requirements of the input optical fiber 2 and the output optical fiber 5, including the numerical aperture NA1 and the core diameter D1 of the input optical fiber 2, the numerical aperture NA2 and the core diameter D2 of the output optical fiber 5, and the operating wavelength λ of the device, by The following formula calculates the mode field diameter ω of the input fiber;

[0054]

[0055]

[0056] where NA is the numerical aperture of the fiber, V is the V value of the fiber, D is the core diameter, ω is the mode field diameter...

Embodiment 1

[0076] The core and cladding diameters of input fiber 2 are 10 μm and 130 μm, NA 0.075, and the core and cladding diameters of output fiber 5 are 25 μm and 400 μm, NA 0.065, respectively.

[0077] 1) Prepare the input optical fiber 2 and the output optical fiber 5, wherein the core diameter of the input optical fiber 2 is 10 μm, the cladding diameter of the input optical fiber is 130 μm, the core diameter of the output optical fiber 5 is 25 μm, and the cladding diameter of the output optical fiber is 400 μm. Strip off a section of the outer cladding of the input fiber 2 close to the end face of the fiber, the stripping length is not less than 10cm, and strip off a section of the outer cladding of the output fiber 5 near the middle position, the stripping length is not less than 20cm.

[0078] 2) The operating wavelength λ of the device is determined to be 1080nm, and the core diameter of the cone waist region 3 of the mode field adapter is calculated to be about 9.9 μm.

[007...

example 2

[0084] 1) The core and cladding diameters of input fiber 2 are 20 μm and 400 μm, NA0.065 respectively, and the core and cladding diameters of output fiber 5 are 25 μm and 400 μm, NA0.065. Strip off a section of the outer cladding of the input fiber 2 close to the end face of the fiber, the stripping length is not less than 10cm, and strip off a section of the outer cladding of the output fiber 5 near the middle position, the stripping length is not less than 20cm.

[0085] 2) The operating wavelength λ of the device is determined to be 1080 nm, and the core diameter of the tapered waist region 3 of the mode field adapter is calculated to be about 20 μm.

[0086]3) Under the condition of about 1400°C, heat the middle section of the output optical fiber 5 stripped of the outer cladding until it is melted, and then use an optical fiber fusion tapered machine to taper the melted output optical fiber 5, so that the mode field after tapered The core diameter of the tapered waist reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap