Physical property testing system for modified asphalt waterproof coiled material

A technology for waterproofing membranes and physical properties, which is applied in the directions of measuring devices, analysis materials, and material thermal analysis, etc. It can solve the problems of affecting the judgment of testers, being in a wrinkled state, and unstable transportation of modified asphalt waterproofing membranes, etc., to achieve convenience The effect of detecting operations, improving accuracy, and facilitating observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

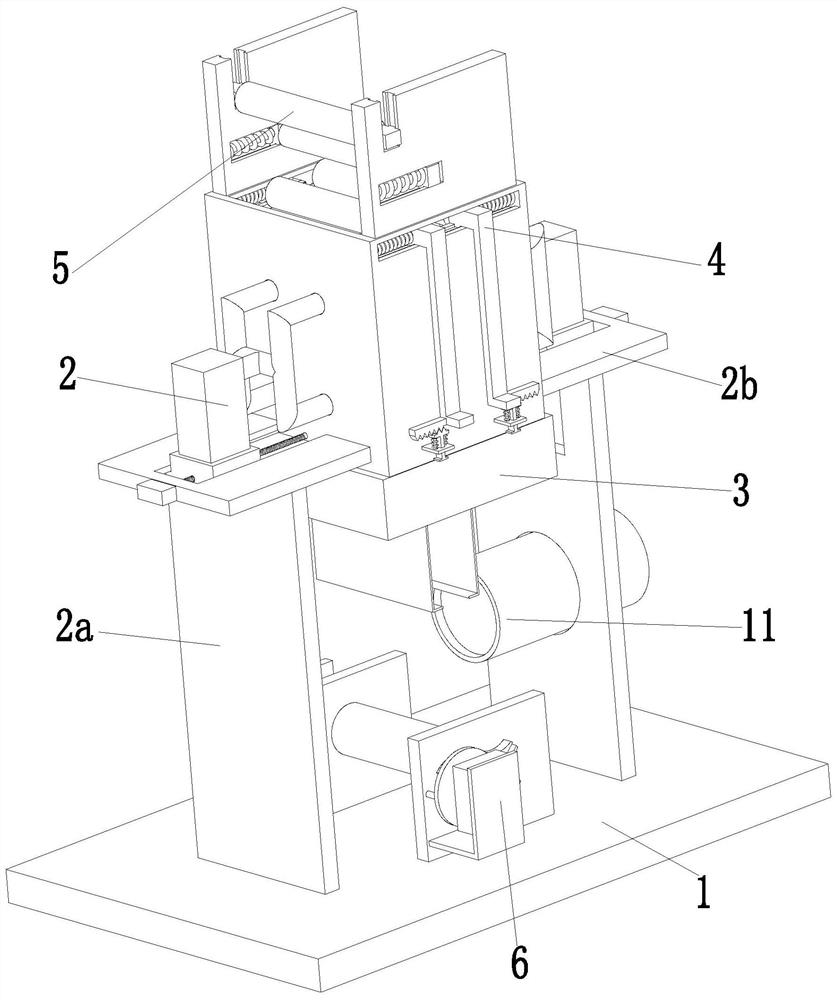

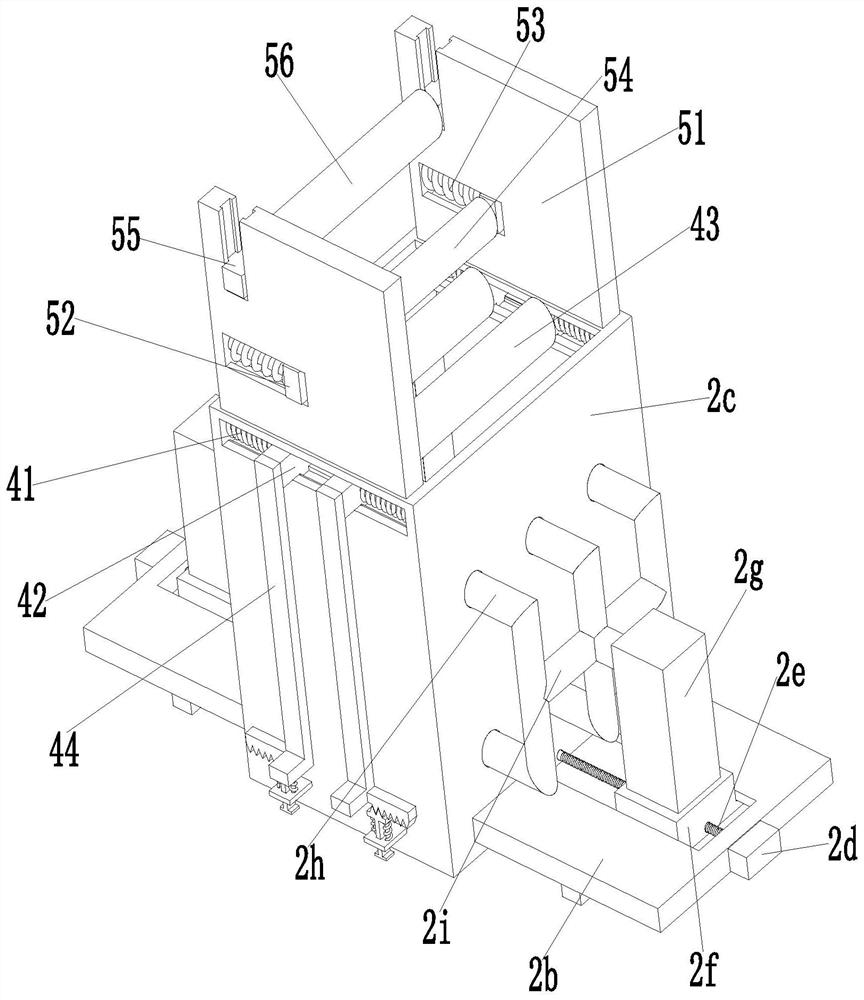

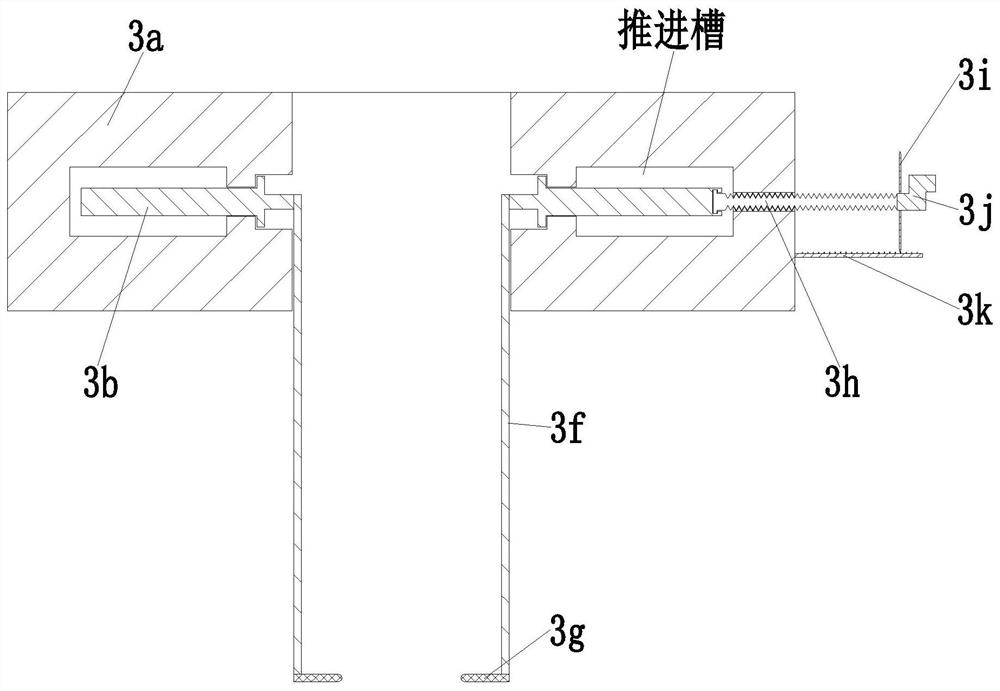

[0031] Such as Figure 1 to Figure 8 As shown, a physical performance testing system of modified asphalt waterproofing membrane, including a base plate 1, a heating device 2, a scraping device 3, a feeding device 4, a roll feeding device 5 and a winding device 6, the base plate 1 A heating device 2 is installed on the top, and a scraping device 3 , a feeding device 4 and a roll feeding device 5 are installed on the heating device 2 , and a winding device 6 is installed in the middle of the bottom plate 1 .

[0032]The coil feeding device 5 includes a square plate 51, a block 52, a return spring rod 53, a pressing round roller 54, a flat block 55 and a coil feeding round roller 56, and the outer wall of the upper end of the heating box 2c is symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com