Floating type cooling tower anti-overflow device and water collecting tray with same

A cooling tower and anti-overflow technology, which is applied to water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of complicated anti-overflow process, troublesome manufacture, and complex structure of anti-overflow devices, etc. problem, to achieve the effect of simple and reliable anti-overflow operation and process, simple structure and improved protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

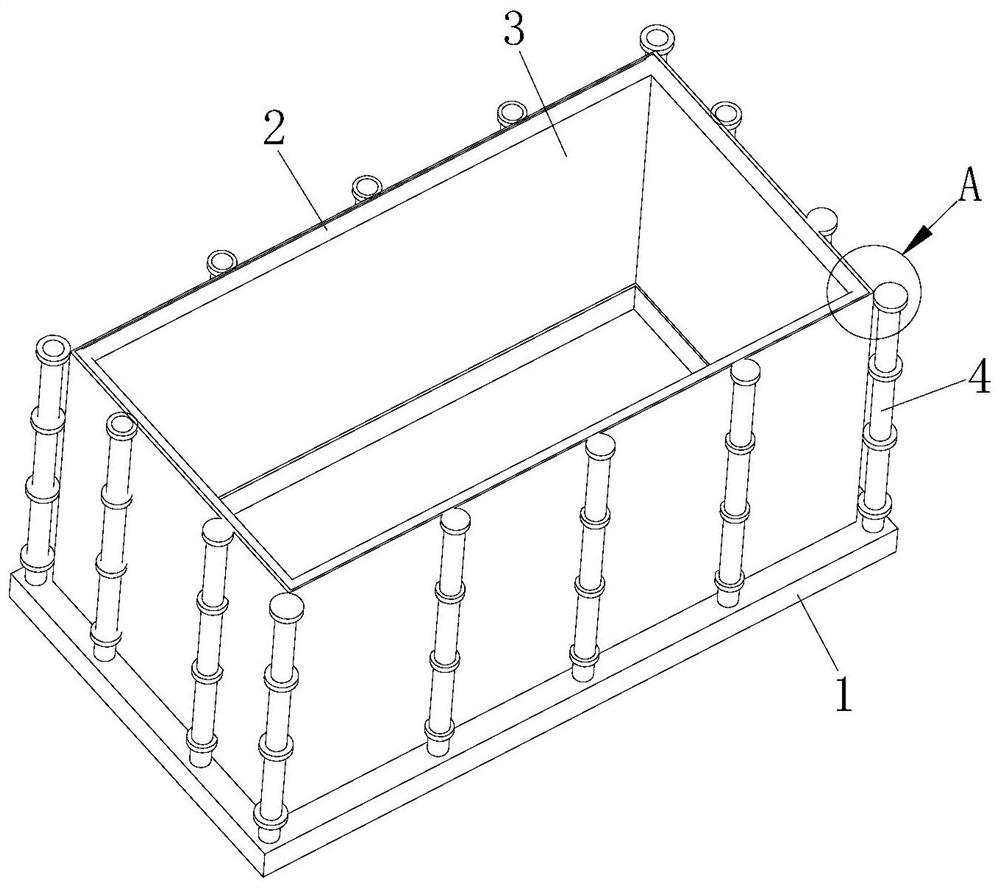

[0043] refer to figure 1 , the present embodiment discloses a floating cooling tower anti-overflow device, including a fence base 1, a floating frame 2, a stretchable waterproof cloth 3 and a strip stretching assembly 4.

[0044] The fence base 1 is a "mouth"-shaped structure surrounded by four square tubes. And the fence base 1 is fixed on the bottom of the water collecting pan in the cooling tower by bolts or clips or welding. A floating frame 2 is arranged above the fence base 1 .

[0045] refer to Figure 4 , the floating frame 2 is a "mouth"-shaped structure surrounded by four round tubes. And the overall length and width of the floating frame 2 is slightly smaller than the overall length and width of the fence base 1 . The floating frame 2 is a structure that is lightweight and can float on the water surface when encountering water. When the water surface is flush with the bottom surface of the floating frame 2, the bottom surface of the floating frame 2 is in cont...

Embodiment 2

[0053] refer to Figure 6 The difference between the second embodiment and the first embodiment is that the cloth strip stretching assembly 4 includes a bottom cylinder 404, a first stop ring 405, a first slider 406, a second stop ring 407, a second slider 408 , the third limiting ring 409 , the third sliding cylinder 410 and the top connecting block 403 . The number of the bottom cylinders 404 is four, and they are respectively arranged at the four corners of the top surface of the fence base 1 . And the bottom cylinder 404 is arranged outside the stretchable water-proof cloth 3 .

[0054] The top of the bottom cylinder 404 is welded with a first limiting ring 405 . The bottom cylinder 404 is sleeved with a first sliding cylinder 406 that can slide up and down inside the bottom cylinder 404 . The bottom of the first sliding cylinder 406 is welded with a first limiting block (not shown) that blocks each other with the first limiting ring 405 .

[0055] A second limiting ri...

Embodiment 3

[0063] The floating frame 2 is a square frame structure surrounded by driftwood. The floating effect of the floating frame 2 is improved to facilitate straightening the telescopic water barrier 3 when the liquid level of the water surface rises.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com