Pintle injector achieving head cooling through jet flow self-impact type membrane

A technology of injector and self-impact, which is applied in the direction of jet propulsion device, machine/engine, rocket engine device, etc. It can solve the problems of high cooling cost, only one-time use, complicated processing, etc., and achieve low processing cost and repeated High usability, improve the effect of atomization and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

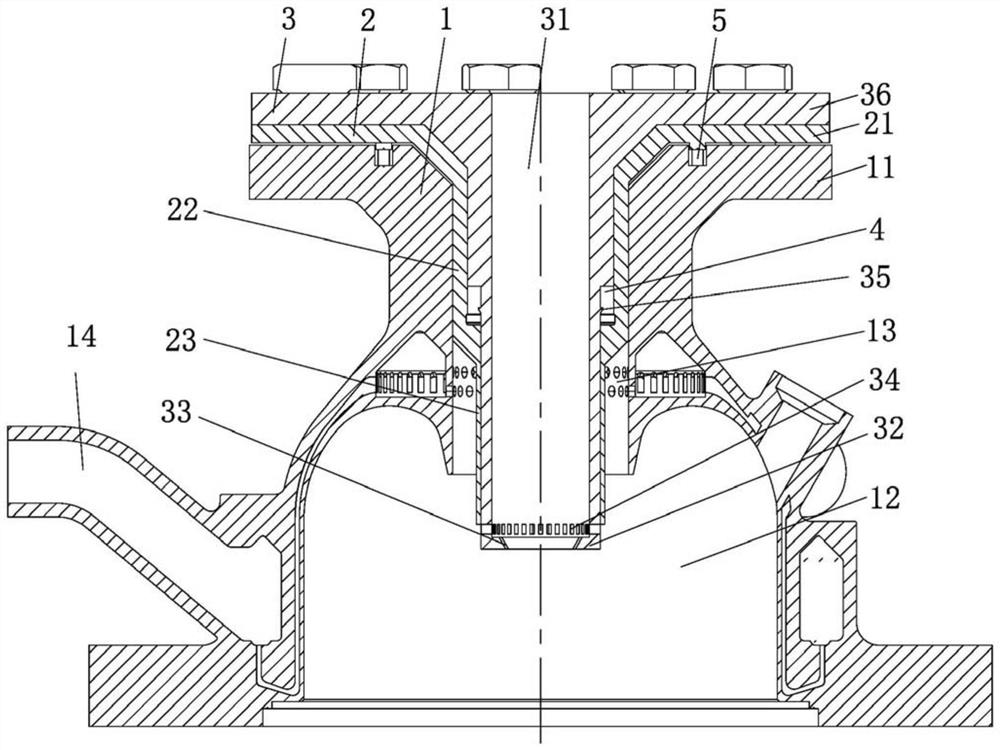

[0024] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

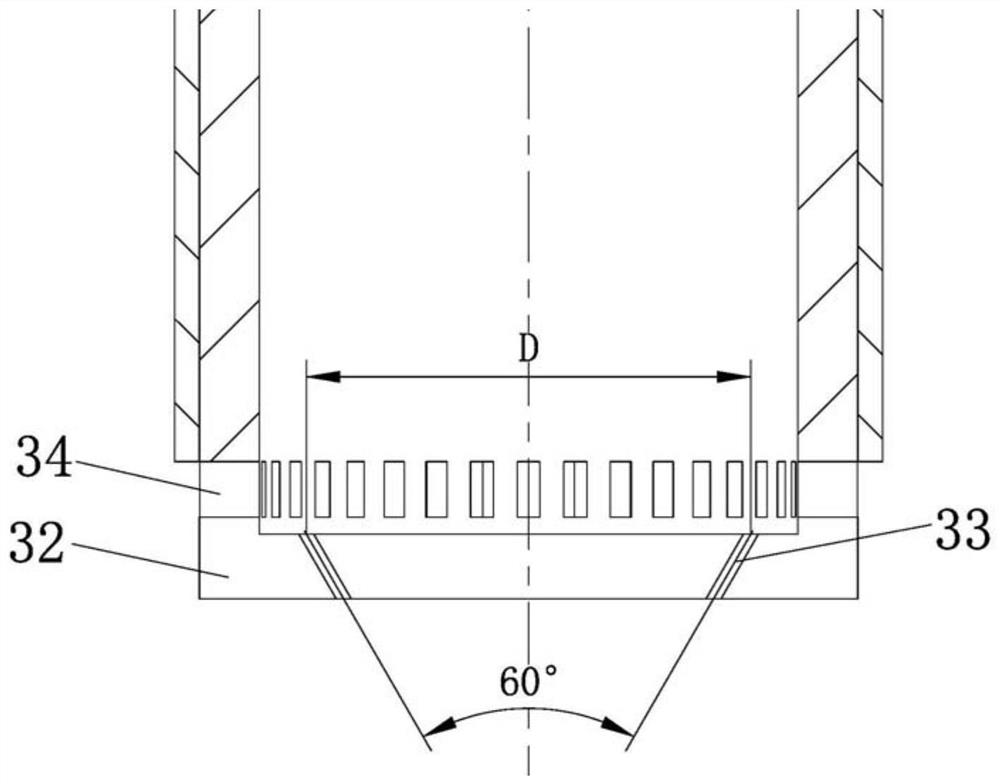

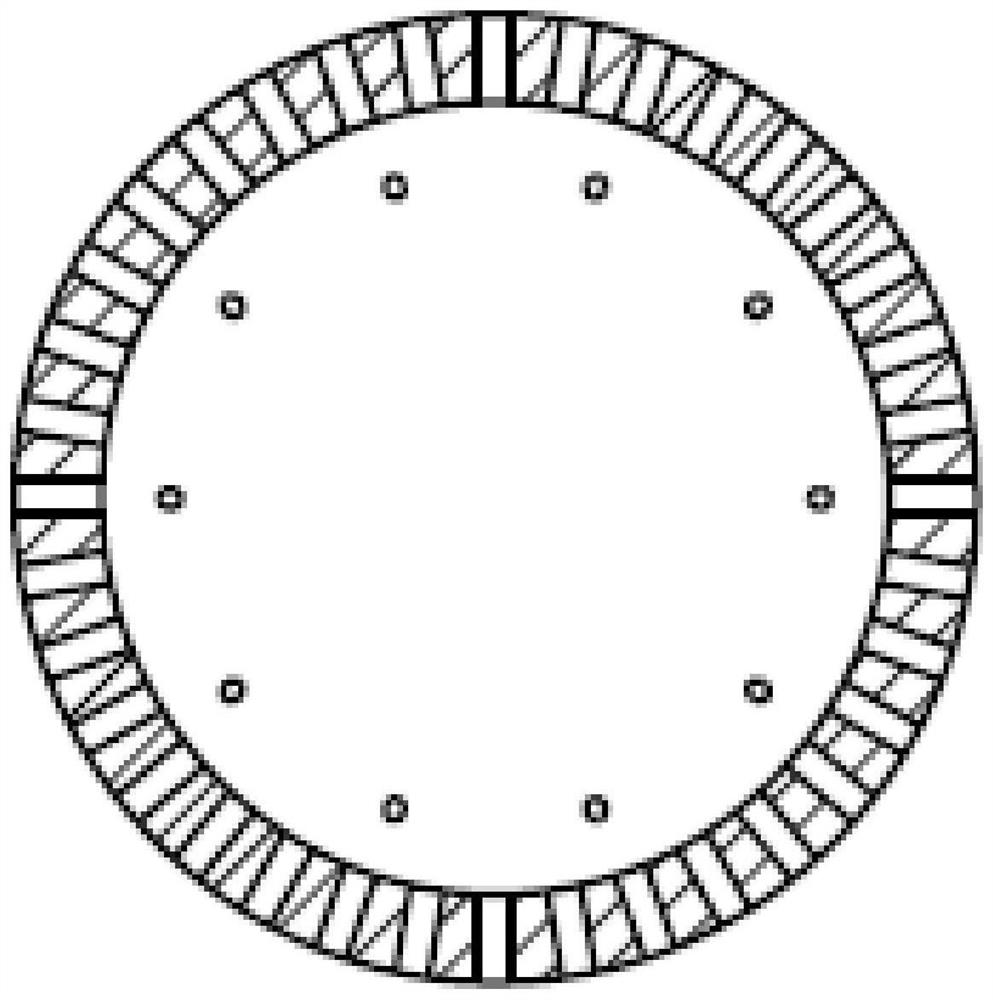

[0025] The present invention provides a needle pintle injector which realizes cooling of the head through jet self-impact film. A reliable way to achieve cooling of the pintle injector head. The cooling structure of the pintle injector of the present invention is mainly composed of a central cylinder and a number of impact holes connected with the inner cavity of the central cylinder. The jet formed by the hole hits a point at a certain distance from the head of the pintle injector, and a conical liquid film is formed at the point of impact. The jet and liquid film can make the pintle head and the returning high-temperature gas in the combustion chamber generate a certain At the same time, after the liquid film is broken, it evaporates and absorbs heat to reduce the temperature near the pintle head, protecting the pint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com