Packaging equipment

A technology of packaging equipment and charging box, which is applied in the directions of packaging, transportation packaging, and food packaging, can solve the problems of manual packaging, such as labor-intensive, unprotected hygiene, and hidden hygiene problems, and achieve smooth transportation and good hygiene conditions. Guaranteed, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

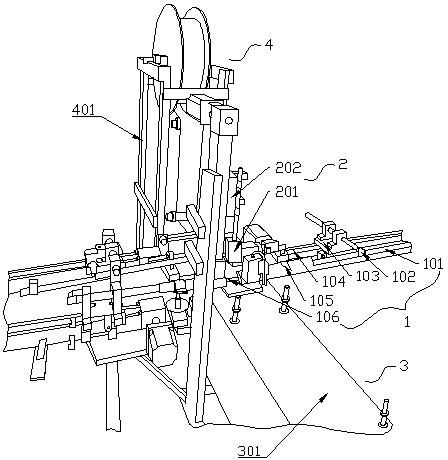

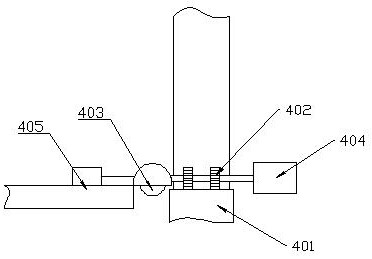

[0062] Such as figure 1 As shown, the present embodiment provides a packaging device, including a feeding part 1, a feeding part 2 and a packaging part 3, and the feeding part 2 is located between the feeding part 1 and the packaging part 3 and accepts the feeding part 1 and the packaging part 3. The packing part 3 and one side of the unloading part 2 are provided with a paper feeding mechanism 4 .

[0063] Specifically, the feeding part 1 includes a feeding trough 101 for carrying materials, and one side of the feeding trough 101 is provided with a pushing plate 102 for pushing the materials forward.

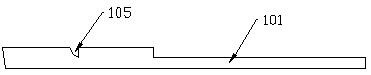

[0064] Such as figure 2 As shown, the feed trough 101 is in the shape of a strip, the end of the feed trough 101 close to the briquetting block 201 is a tubular structure, and the rest of the feed trough 101 is a groove structure with an open top; the feed trough 101 tubular structure is close to The end surface of the pressing block 201 is a forward inclined surface, and on...

Embodiment 2

[0095] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are: Image 6 , Figure 7 As shown, in this embodiment, one side of the second roller 304 is provided with a third roller 307, and the third roller 307 is located on the side of the second roller 304 away from the first roller 303, and the first roller Outer edges of the shaft 303 , the second roller shaft 304 and the third roller shaft 307 protrude above the charging box 302 . The third roller 307 can share the pressure and friction force applied to the second roller 304 by the top surface of the packaging channel 301 , so as to slow down the wear of the second roller 304 and prolong the service life of the charging box 302 .

Embodiment 3

[0097] The features of this embodiment that are the same as those of the preceding embodiments will not be described in detail. The features of this embodiment that are different from those of the preceding embodiments are as follows: Figure 9 As shown, in this embodiment, the side wall of the charging box 302 and the bottom surface 311 form a flexible connection so that the side wall has a degree of freedom of movement in the axial direction of the first roller shaft 303, and the two sides of the charging box 302 One or more springs 312 are connected between the two side walls.

[0098] Specifically, the mounting hole connecting the bottom surface 319 of the charging box 302 with the side wall in this embodiment is an oblong hole 320, the first roller 303, the second roller 304, the third roller 307, the first roller 305 and the second roller The two ends of the two rollers 306 leave a movable space for the side walls of the charging box 302 to realize the change of the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com