Low-temperature-resistant PVC covering cloth and production method thereof

A production method and low temperature resistance technology, applied in the textile field, can solve the problems of poor stability, poor folding resistance, poor cold resistance, etc., and achieve the effects of high compatibility, long service life and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] As a preferred embodiment, the preparation of the PVC coating 3 includes the following raw materials in parts by weight:

[0056]

[0057] PVC coating 3 is plasticized with vinyl chloride copolymer, which has high compatibility with PVC resin, which solves the migration problem of plasticizer in low temperature environment or during long-term use, thus ensuring the PVC coating 3 and the stability of the tarpaulin in harsh environments.

[0058] As a preferred embodiment, the preparation process of the vinyl chloride copolymer is as follows: 70-90wt% vinyl chloride, 10-30wt% butyl linoleate, 0.3-1wt% sodium lauryl sulfate and 0.3-1 wt% potassium persulfate are put into a reaction kettle, the temperature is controlled at 45-60° C., and stirred for 4-6 hours to obtain the required vinyl chloride copolymer.

[0059] The beneficial effect of adopting the technical solution of this embodiment will be further described below through several groups of examples and comparati...

Embodiment 1

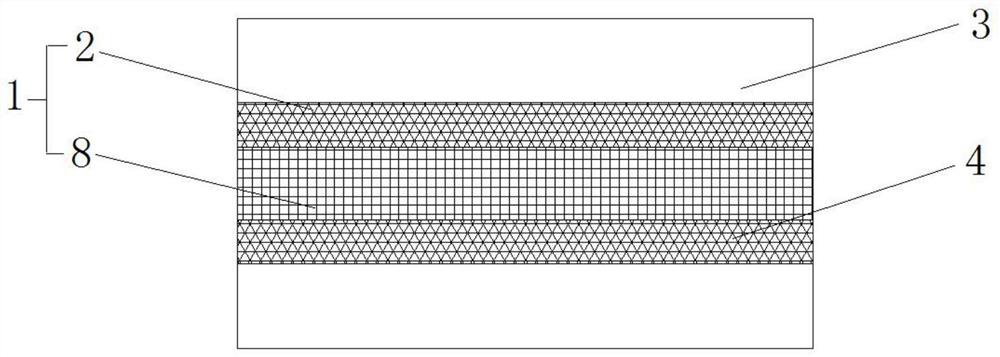

[0061] The production method of PVC tarpaulin in the present embodiment, concrete steps are as follows:

[0062] Step 1: Opening, mixing, and combing 40wt% polyester fiber with a specification of 3D*51mm and 60wt% polyester fiber with a specification of 1.5D*51mm to form a fiber web layer;

[0063] Step 2, transporting the fiber mesh layer to the middle of the two layers of woven cloth layers arranged up and down, and stitching and compounding the carbon fiber filaments to obtain the base cloth layer;

[0064] Step 3: Apply PVC coating on the upper and lower sides of the base cloth layer to obtain a PVC tarpaulin.

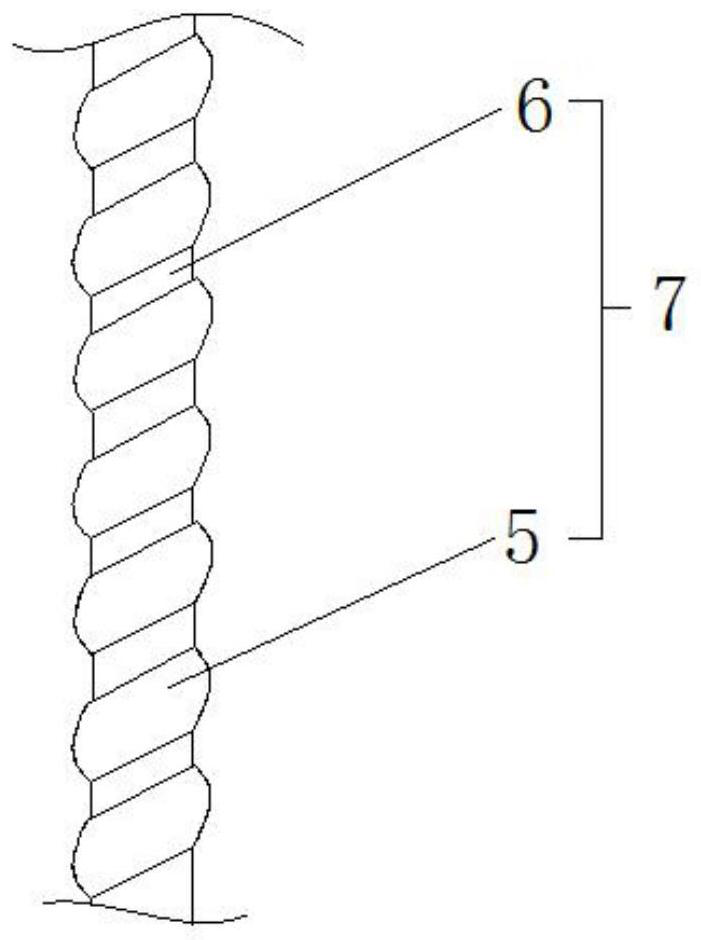

[0065] Wherein, the weft yarn of the woven fabric layer in step 2 is a core-spun yarn blended with carbon fiber as the skin and nylon filament as the core, and the use ratio of carbon fiber yarn and nylon fiber yarn is 1:1, and the mixing weight percentage It is 40%: 60%, the fineness of carbon fiber is 4D, and the length is 51mm; the fineness of nylon fiber is 2D...

Embodiment 2

[0068] The production method of PVC tarpaulin in the present embodiment, concrete steps are as follows:

[0069] Step 1: Opening, mixing, and combing 30wt% polyester fiber with a specification of 3D*51mm and 70wt% polyester fiber with a specification of 1.5D*51mm to form a fiber web;

[0070] Step 2, transporting the fiber mesh layer to the middle of the two layers of woven cloth layers arranged up and down, and stitching and compounding the carbon fiber filaments to obtain the base cloth layer;

[0071] Step 3: Apply PVC coating on the upper and lower sides of the base cloth layer to obtain a PVC tarpaulin.

[0072] Wherein, the weft yarn of the woven fabric layer in step 2 is a core-spun yarn blended with carbon fiber as the skin and nylon filament as the core, and the use ratio of carbon fiber yarn and nylon fiber yarn is 1:3, and the mixing weight percentage It is 30%: 70%, the fineness of carbon fiber is 2.5D, and the length is 51mm; the fineness of nylon fiber is 1.5D, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com