Machining jig with automatic positioning and fixing effects

A fixture and fixing seat technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of unstable fixing of arc-shaped workpieces such as balls, small contact area between workpieces and fixing parts, and workpieces not up to standard, etc., to achieve Significant fixing effect, stable processing and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

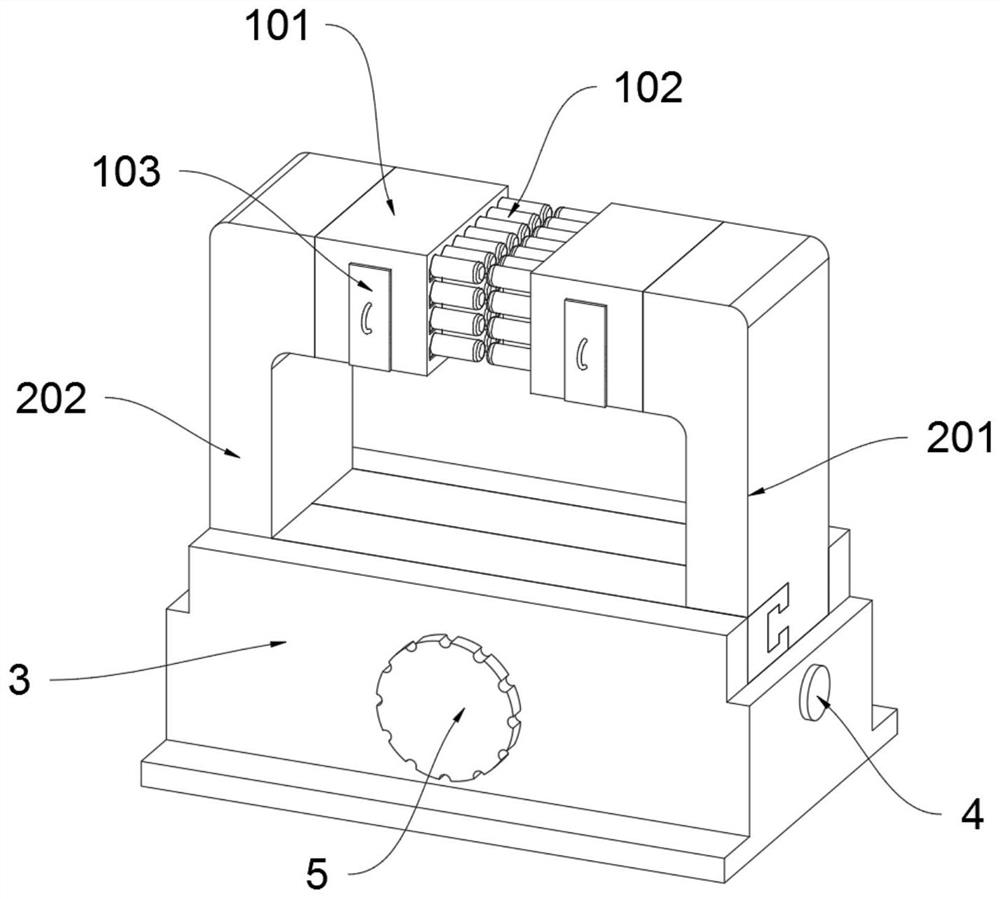

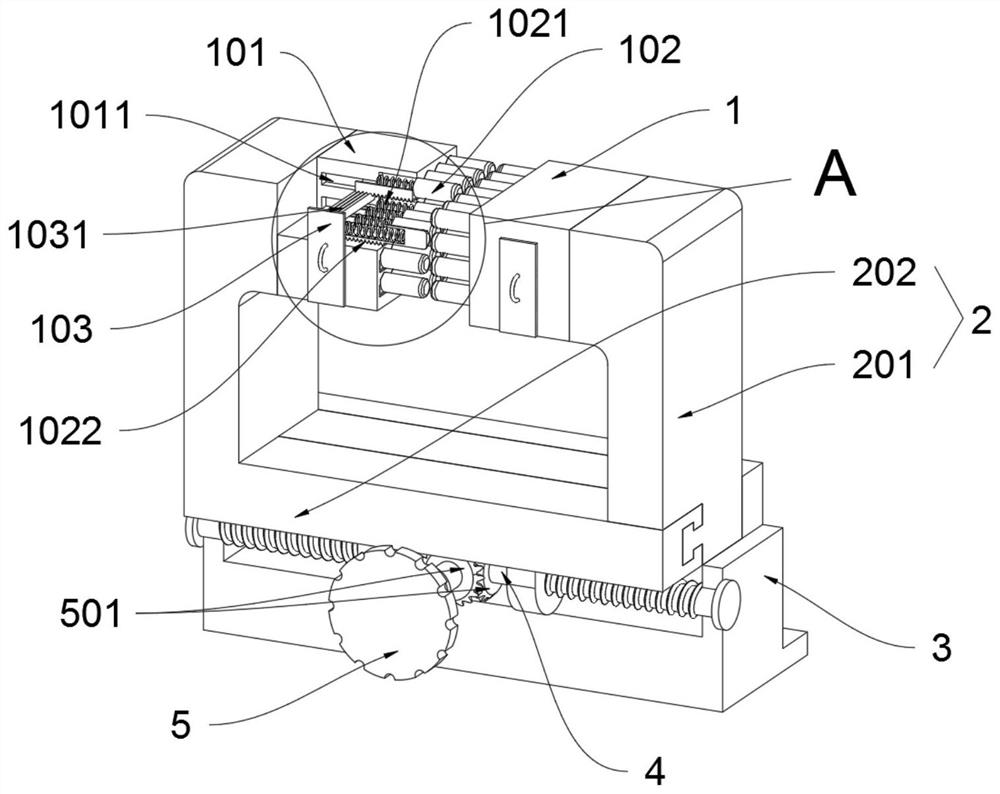

[0032] as attached figure 1 to attach Figure 7 Shown:

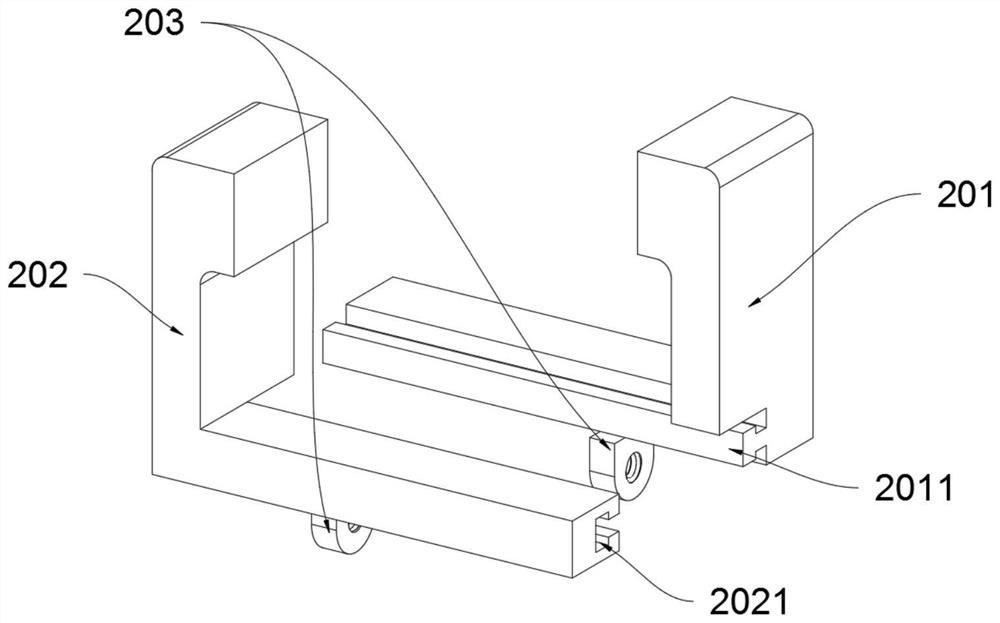

[0033]The invention provides a processing jig with automatic positioning and fixing effects, comprising a special-shaped positioning mechanism 1, a clamping arm mechanism 2, a mounting seat 3, a linkage rod 4 and an adjusting rod 5; the special-shaped positioning mechanism 1 is composed of a positioning shell 101, a special-shaped The interference rod 102 and the special-shaped positioning rod 103 are composed; the clamping arm mechanism 2 is composed of the right clamping arm 201 and the left clamping arm 202; the positioning shell 101 is screwed and fixed on the top of the clamping arm of the clamping arm mechanism 2; the special-shaped conflicting rod 102 is plugged in In the inside of the positioning shell 101; the special-shaped positioning rod 103 is plugged in the inside of the positioning shell 101 from the side; the mounting base 3 is screwed and fixed on the top surface of the working platform; the right jig a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com