Intelligent electric spark cutting machine tool

A cutting machine tool and electric spark technology, applied in the field of machine tools, can solve the problems of inability to adjust the overall height, inability to freely move and adjust, and easy occurrence of sparks, etc., to increase the anti-splash protection function, ensure cutting convenience, and avoid sparks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

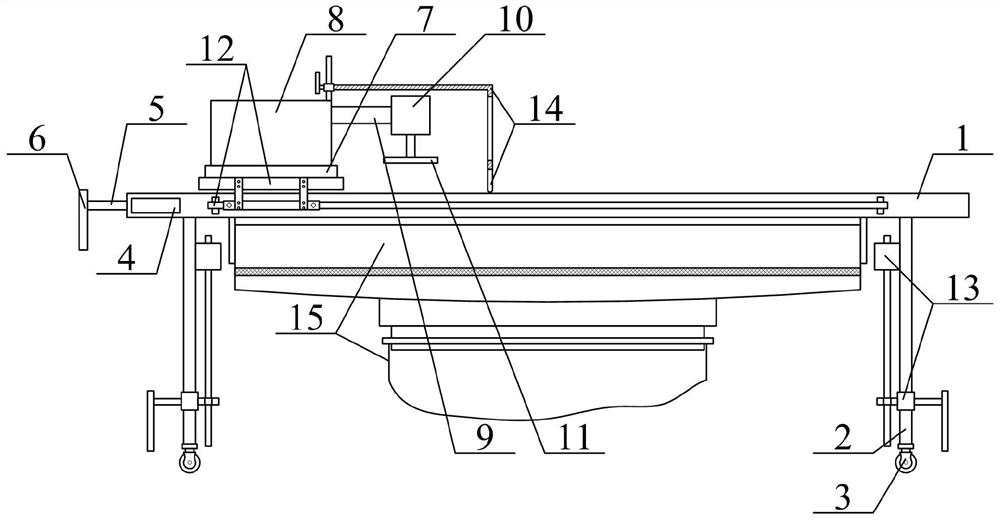

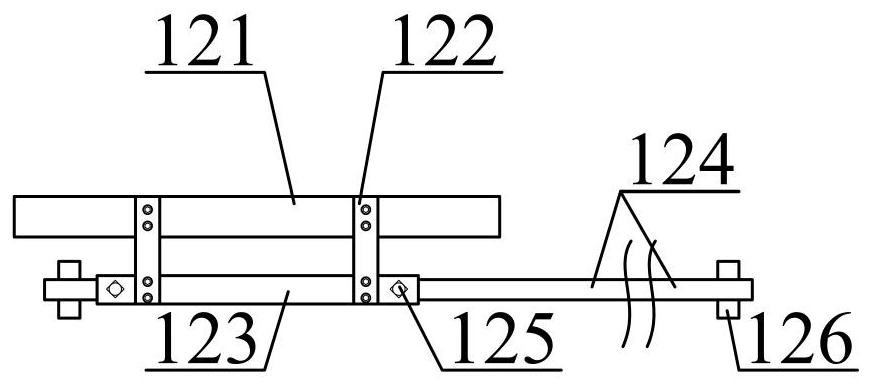

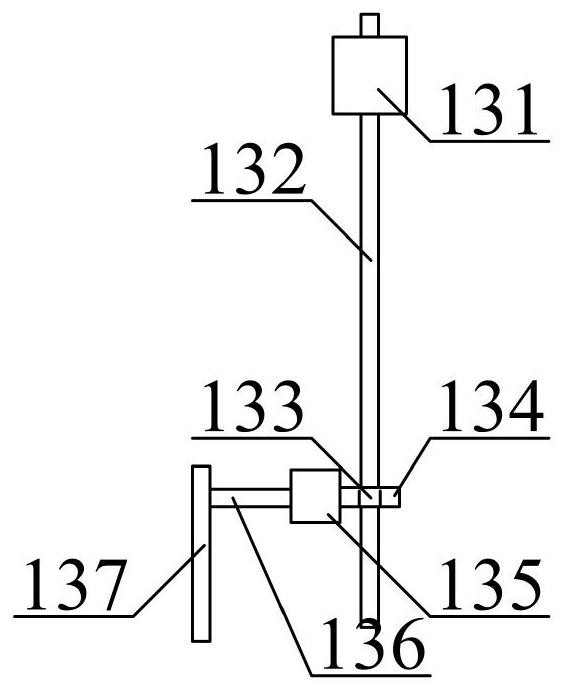

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, an intelligent EDM machine tool includes machine tool body 1, machine column 2, mobile casters 3, intelligent control panel 4, pull rod 5, push-pull handle 6, mounting seat 7, electric control box 8, connecting rod 9, EDM cutting machine body 10, cutting head 11, freely movable adjustment rail structure 12, height adjustment support machine structure 13, adjustable splash protection cover structure 14 and debris splash collection box structure 15, the machine tool body 1 The four corners of the bottom are all connected with mobile casters 3 through the machine column 2; the left side screw of the front part of the machine tool body 1 is connected with an intelligent control panel 4; 6. The upper part of the mounting seat 7 is bolted to an electric control box 8; the upper right side of the electric control box 8 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com