Cold-rolled steel sheet metal part bending process

A technology of sheet metal parts and cold-rolled steel, which is applied in the field of bending process of cold-rolled steel sheet metal parts, can solve the problems of easy deviation of size and angle, and achieve the goal of improving accuracy, improving bending efficiency, and not easy to spring back Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

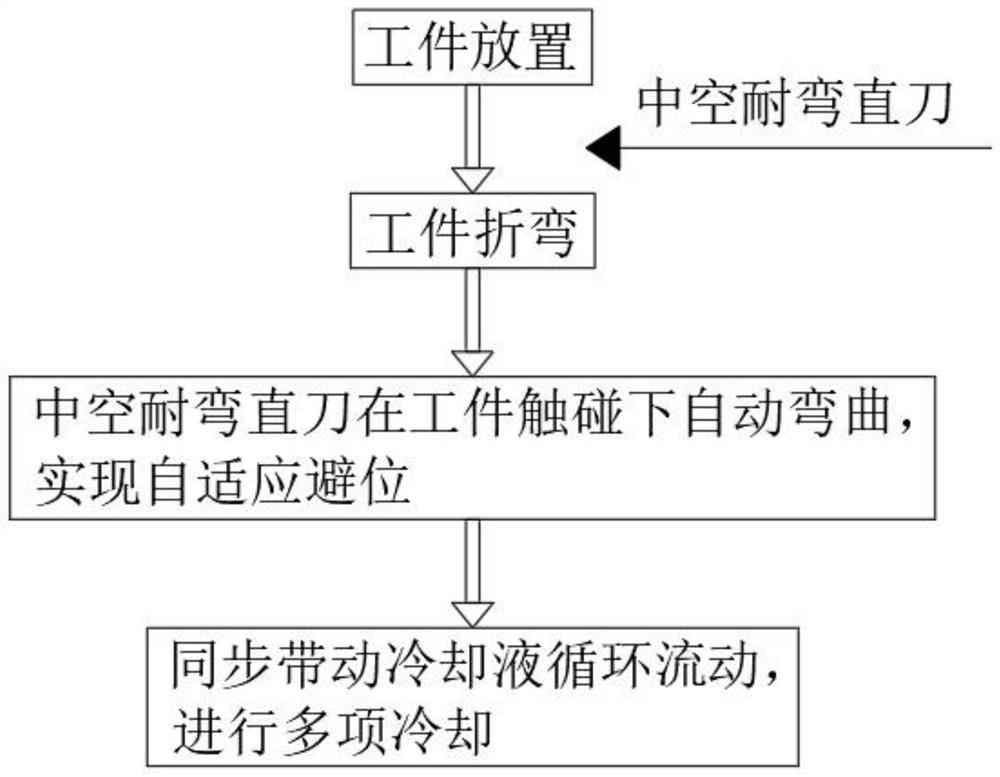

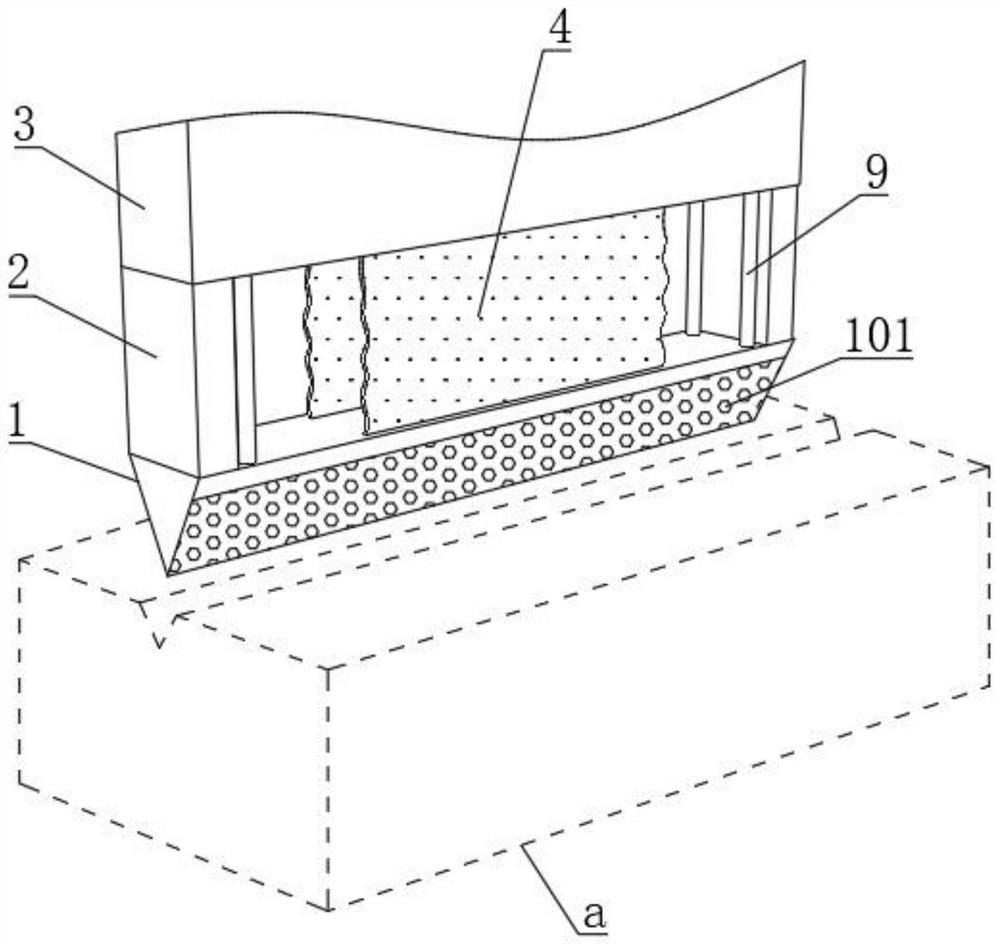

[0052] see figure 1 and figure 2 , a cold-rolled steel sheet metal bending process, comprising the following steps:

[0053] S1. Workpiece placement: Place the cold-rolled steel sheet metal parts to be processed stably on the bending table ( figure 2 Indicated by a), so that the bending part is directly facing the lower side of the hollow bending-resistant straight knife;

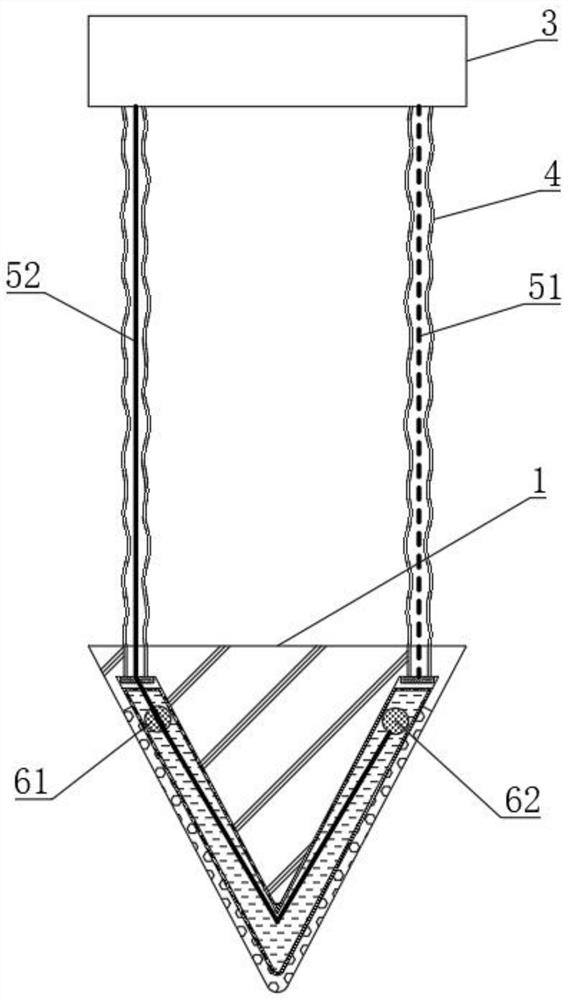

[0054] S2. Bending: Start the bending equipment, drive the hollow bending-resistant straight knife to move down, squeeze the cold-rolled steel sheet metal parts, and make them bend to the required angle;

[0055] S3. Adaptive avoidance: When the cold-rolled steel sheet metal part touches the side end of the hollow bending-resistant straight knife during the bending process, the hollow bending-resistant straight knife can be bent accordingly, and the cold-rolled steel sheet metal part is automatically Adapt to avoidance;

[0056] S4. Multiple cooling: At the same time, the bending process of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com