Rolling method for metal composite plate with prefabricated crossed corrugated interface

A metal clad plate and cross-corrugation technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of low bonding strength, warpage and edge cracking of metal clad plates, and solve the problem of plate warpage Problems, small reduction, simple effect of blank making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

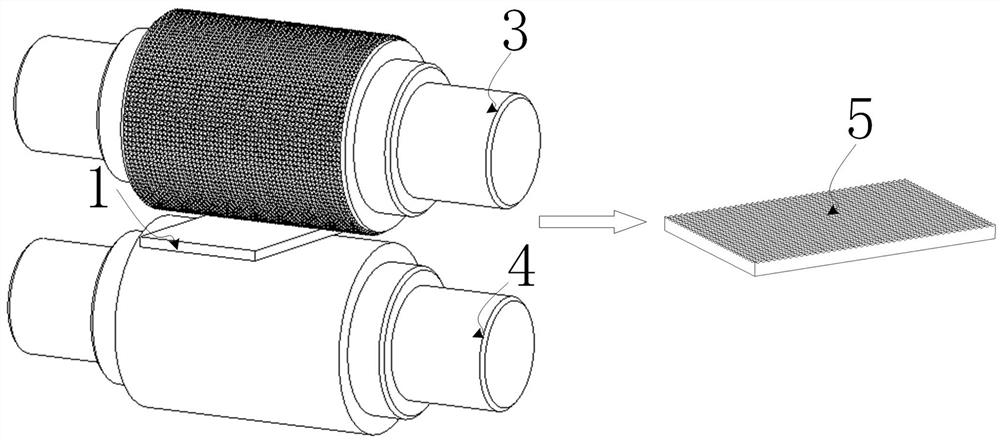

[0025] refer to Figure 1-6 , a method for rolling a metal clad plate with a prefabricated cross corrugated interface, comprising the following steps:

[0026] S1. Substrate and compound board preparation: Select the 5052 brand aluminum alloy plate with relatively small deformation resistance as the substrate 1, the length, width and height are 100, 100, and 3 mm respectively, and select the AZ31 brand magnesium alloy plate with relatively large deformation resistance as the compound board 2. The length, width and height are 100, 100, and 1mm respectively;

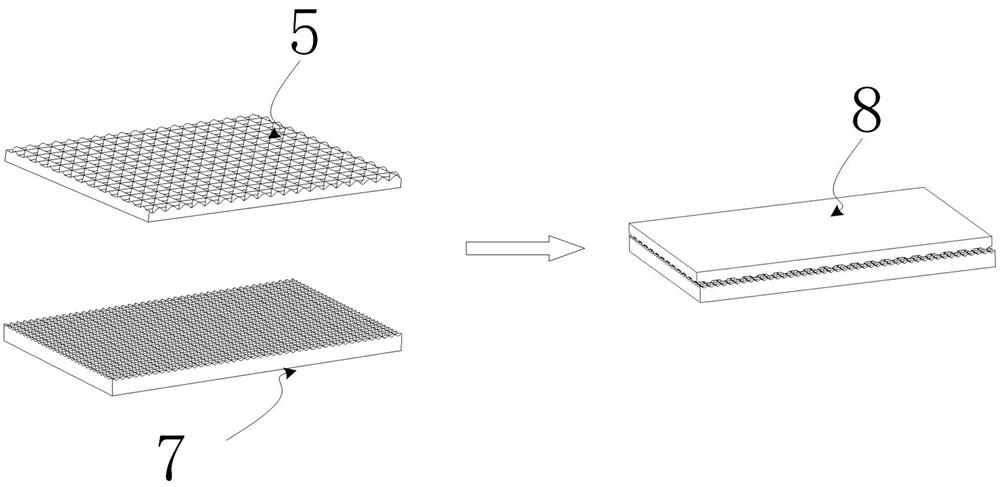

[0027] S2. Blank making: Put the base plate 1 into a corrugated roll mill for rolling. The upper roll of the corrugated flat rolling mill is a cross corrugated roll a3. 2mm, the lower roll is a flat roll 4, the average radius of the upper and lower rolls is 75mm, and the reduction rate is 10%. After rolling, the upper surface of the substrate 1 is a cross corrugated surface, and the lower surface is a plane to form a subs...

Embodiment 2

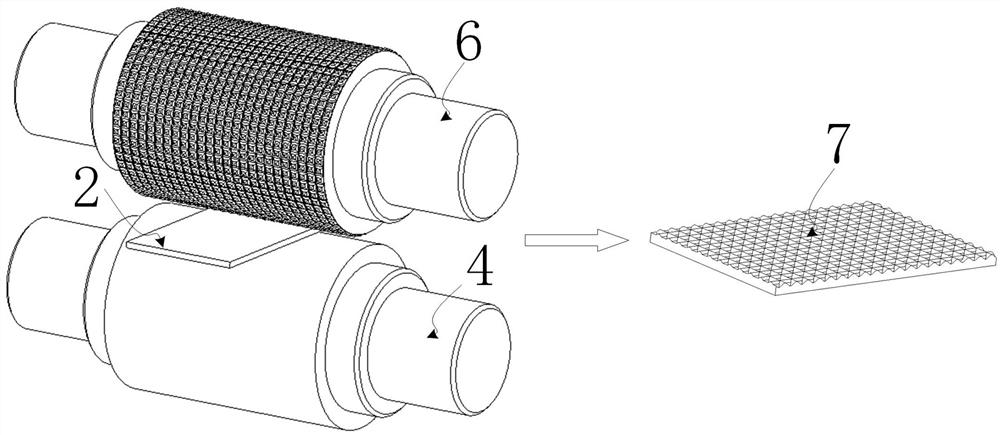

[0032] refer to Figure 1-6 , a method for rolling a metal clad plate with a prefabricated cross corrugated interface, comprising the following steps:

[0033] S1. Substrate and compound board preparation: Select the 5052 brand aluminum alloy plate with relatively small deformation resistance as the substrate 1, the length, width and height are 100, 100, and 3 mm respectively, and select the AZ31 brand magnesium alloy plate with relatively large deformation resistance as the compound board 2. The length, width and height are 100, 100, and 1 mm respectively.

[0034] S2. Billet making: put the base plate 1 into a corrugated roll rolling mill for rolling, the upper roll of the corrugated flat rolling mill is a cross corrugated roll b6, and the radial section equation of the cross corrugated roll b6 is Where R is the radius of the cross corrugated roller b6, 0≤t≤1; the equation of the axial section line is Wherein 0≤t≤1, the reduction rate is 10%, the linear speed of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com