A cross shaft cleaning device

A cleaning device and cross shaft technology, applied in cleaning methods and utensils, liquid cleaning methods, chemical instruments and methods, etc., can solve the problems of cross shaft residual oil and metal debris, poor cleaning effect of cross shaft, etc., to achieve Ensure normal transmission, ensure smooth flipping, and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

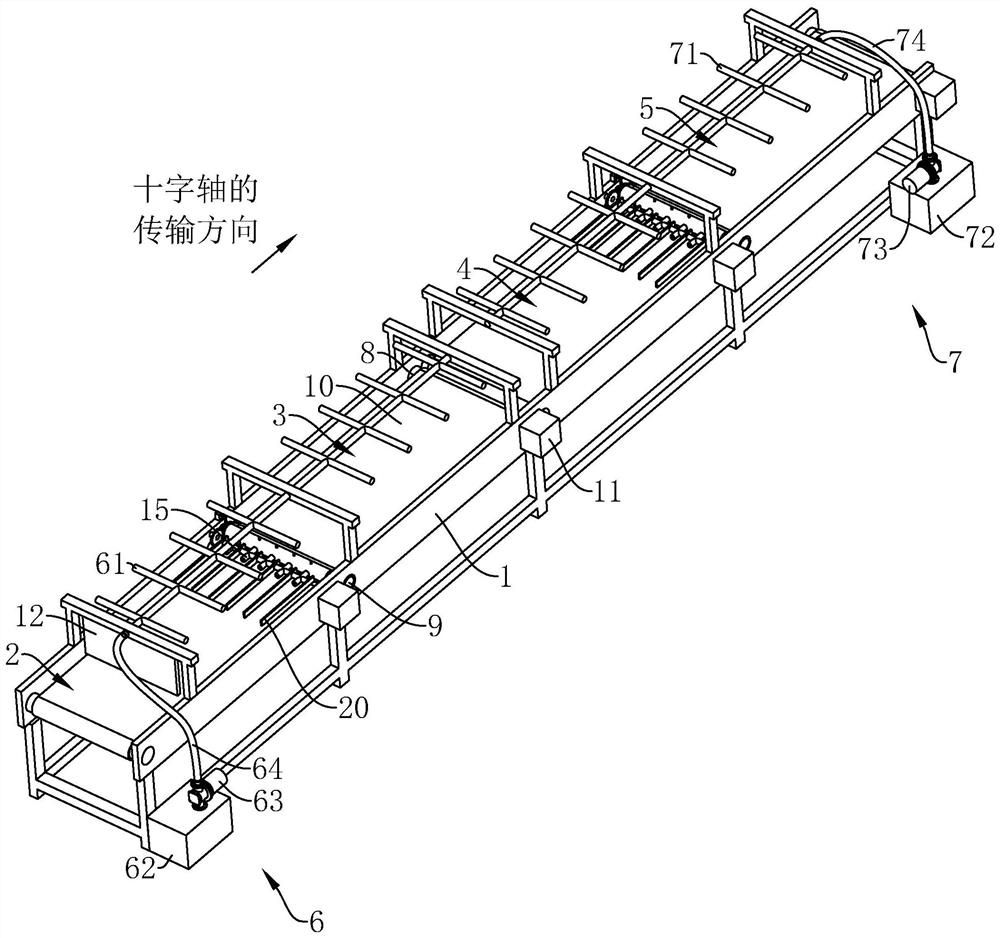

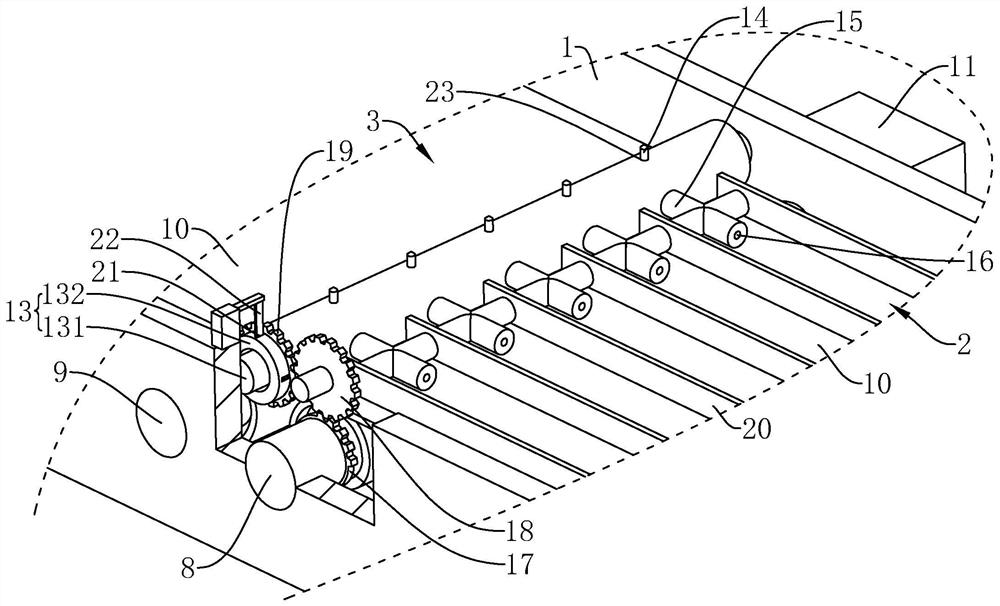

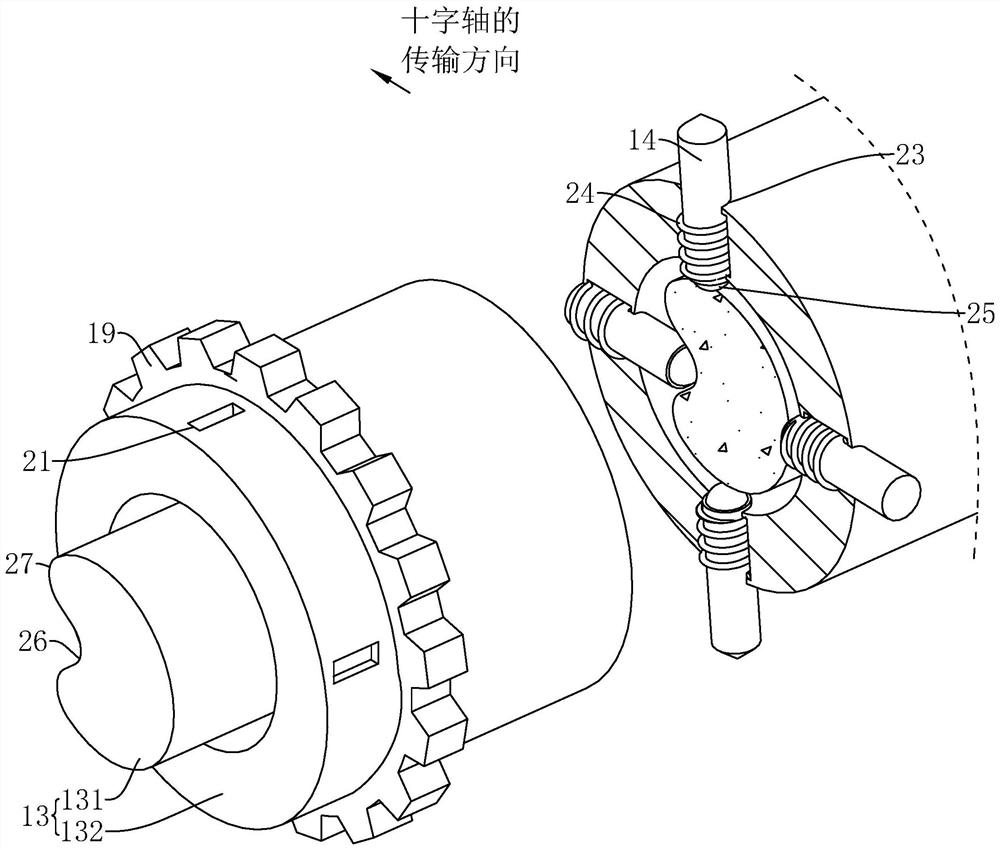

[0033] Contraction below Figure 1-3 Further detailed description of the present application.

[0034] Refer figure 1 , A cross shaft cleaning device, including a rack 1, a first transfer belt 2, a second transmitted belt 3, a third conveyor belt 4, and a fourth transfer belt 5, a third conveyor belt 4, and a fourth transfer belt 3, a third conveyor belt 4, and a fourth transmission belt 5, and a third conveyor On the frame 1 and located above the first spray tube 61 above the first transfer belt 2 and the second drive zone, the first box of the frame 1 is placed on the frame 1 for the first box 62 of the detergent, mounted in the first box 62 The first pump body 63 in which the first box 62 is connected is connected to the first connecting tube 64 between the first pump body 63 and the first spray tube 61, and is fixed to the frame 1 and located in the third conveyor belt. 4 and the second spray tube 71 above the fourth transmission belt, placed on the frame 1 side for the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com