MOS tube voltage difference automatic adjusting device and method

A MOS tube, automatic adjustment technology, applied in the direction of secondary battery repair/maintenance, secondary battery charging/discharging, electrical components, etc. problems such as small voltage drop, to achieve the effect of improving heat dissipation, reducing power consumption, and improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

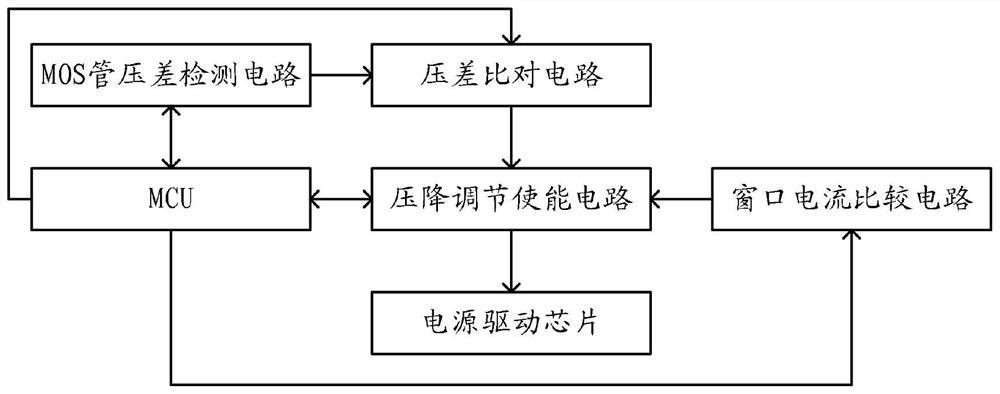

[0038] The general idea of the technical solution in the embodiment of this application is as follows: compare the front-end voltage value FB_VOUT and the back-end voltage value VF_MOS by setting the MOS tube pressure difference detection circuit in real time, and set the window current comparison circuit to compare the output current value FB_IOUT and the current standard in real time The value ICON_SET, based on the comparison result, enables the voltage drop adjustment enabling circuit to work, adjusts the front-end voltage output value V_SET and the divided voltage value V_SET_F; the MCU sets the back-end voltage value VF_MOS based on the front-end voltage output value V_SET and outputs it to the MOS tube pressure difference detection circuit , the power driver chip sets the output voltage of the front-end power supply based on the divided voltage value V_SET_F, so as to realize adaptive adjustment of the voltage difference of the MOS tube, thereby reducing the power consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com