Precise design method for casting shrinkage size based on local envelope density

A design method and casting shrinkage technology, applied in the direction of constraint-based CAD, design optimization/simulation, special data processing applications, etc., can solve the problems of large dimensional accuracy error of castings and insignificant accuracy effect, and achieve the solution of large precision error, The design method is reasonable and feasible, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: present embodiment a kind of accurate design method of casting shrinkage size based on local enveloping density, finish according to the following steps:

[0021] 1. Divide the test model into several local envelopes according to the contraction center ray division method, first calculate the local envelope density of any local envelope, and according to the quadratic relationship curve between the local envelope density and the shrinkage rate, get Calculate the shrinkage of the local envelope, and then use the same method to obtain the shrinkage of all the local envelopes of the test model;

[0022] 2. Convert the shrinkage rate of all local envelopes of the test model into the shrinkage rate of the same part on the casting. The conversion formula is as follows:

[0023] ε li = α 1 ·ε 1 +α 2 ·ε 2 +…+α n ·ε n +(1-α 1 -α 2 -...-α n )·ε 0

[0024] In the formula, ε n Represents the shrinkage rate of the nth local envelope of the test ...

specific Embodiment approach 2

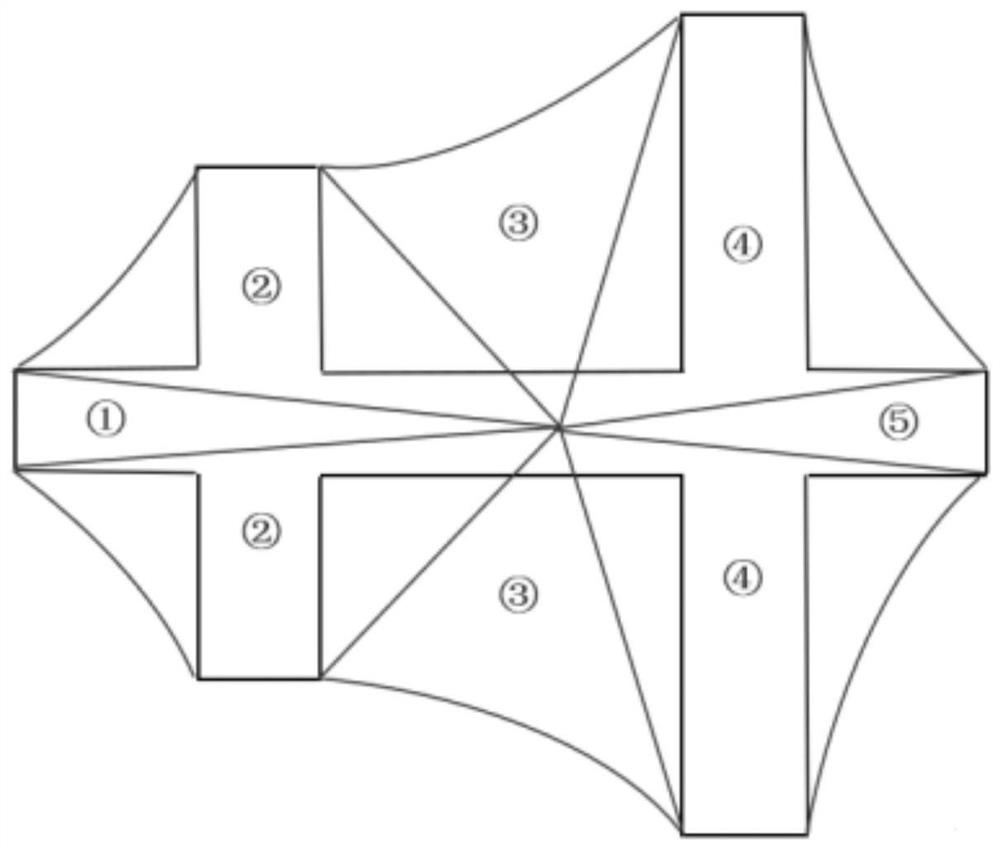

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the shrinkage center ray division method described in step one includes the following steps: first determine the shrinkage center of the test model and the envelope of the test model, and then start from the shrinkage Make several rays from the center to the envelope of the test model, and the closed space formed by two adjacent rays and the edge of the envelope is a local envelope.

[0029] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the shrinkage center of the test model is the center of mass of the test model.

[0031] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com