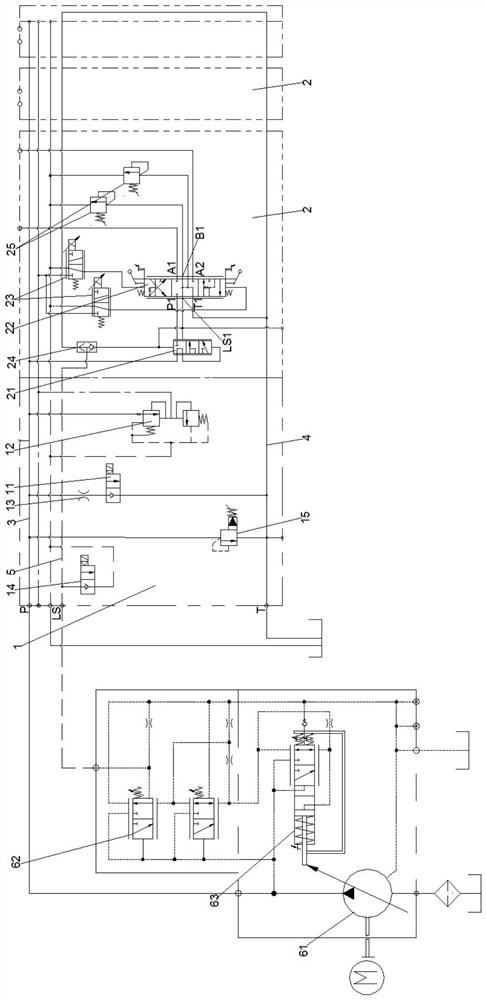

Load-sensitive multi-way valve, boom hydraulic control system and concrete pump truck

A load-sensitive, multi-way valve technology, used in fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc. Guaranteed service life, good flow stability, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0041] In addition, the terms "first" and "second" are only used for the purpose of description, and cannot be understood as indicating or implying relative importance or implicitly specifying the number of indicated technical features. Therefore, the terms "first", "second" are limited to A "second" feature may explicitly or implicitly include one or more of said features.

[0042] In the description of the present invention, it should be noted that unless otherwise specified and limited, the terms "installation", "setting", and "connection" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection. A connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com