Engine controller for extended-range hybrid unmanned aerial vehicle

An engine controller and hybrid power technology, applied in engine control, machine/engine, electrical control, etc., can solve the problems of engine temperature being fixed at a certain speed, tracking, and unable to adjust fuel injection quantity and ignition timing, etc., to achieve Low energy consumption, improved economy, and the effect of ensuring flight safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments.

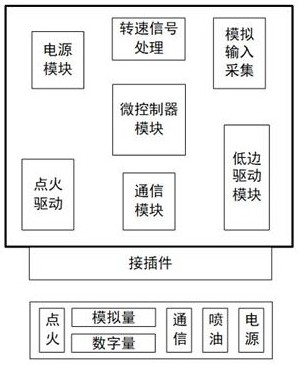

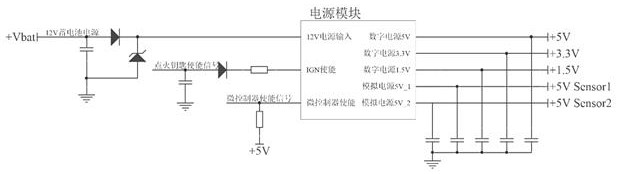

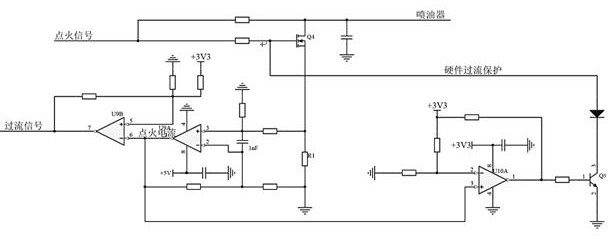

[0022] Such as figure 1 As shown, the engine controller for the extended-range hybrid unmanned aerial vehicle of the present invention includes a circuit board and a connector, wherein the circuit board is provided with a microcontroller module, a power supply module, a speed signal processing module, a communication Module, analog input module, low-side drive module and ignition drive module, the microcontroller module performs control instruction analysis and processing and post-processing of collected data, the microcontroller module is connected with the power supply module, speed signal processing module, The communication module, the analog input module, the low-side drive module, and the ignition drive module are electrically connected; the connector is provided with an analog signal interface, a digital signal interface, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com