PC structure grouting sleeve connection construction method

A grouting sleeve and construction method technology, which is applied to structural elements, building components, building structures, etc., can solve the problems of lack of on-site construction quality control regulations and specifications, and the on-site connection quality is difficult to meet the design requirements, and achieves convenient construction and installation. Simple and effective to ensure connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

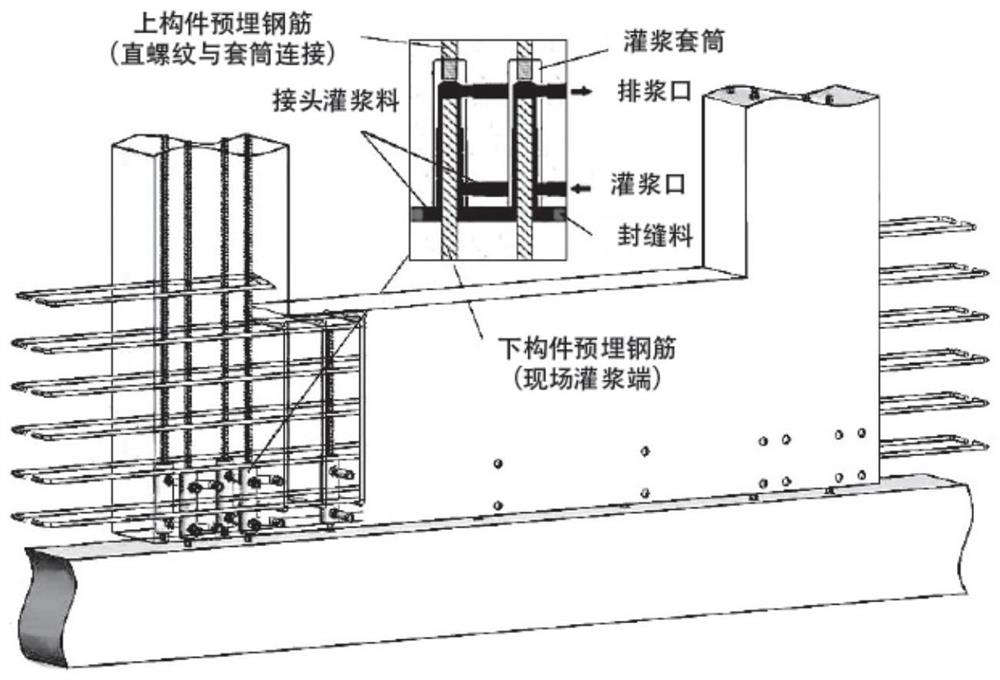

[0023] refer to Figure 1-2 , PC structure grouting sleeve connection construction method, including the following steps:

[0024] In the present invention, the preparation of the connection part; S1. Before construction, the connection part needs to be prepared at first, and the specific steps are to clean the base layer of the structure to make it reach a clean state; measure the boundary line and control line of the control member; adjust the bolt Make its elevation the same as the design elevation at the bottom of the component.

[0025] Preferably, the sub-compartment and its surroundings are blocked before the hoisting; S1. Use the method of sub-compartment grouting, and control the length of the grouted single compartment within 150cm. When the width of the PC wallboar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com