Viscosity reducer, preparation method of viscosity reducer and method for reducing viscosity of fermented mash

A kind of technology of fermentation mash and viscosity reducing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

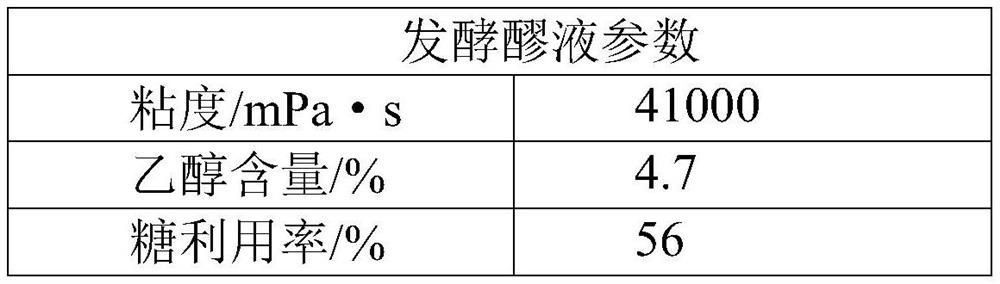

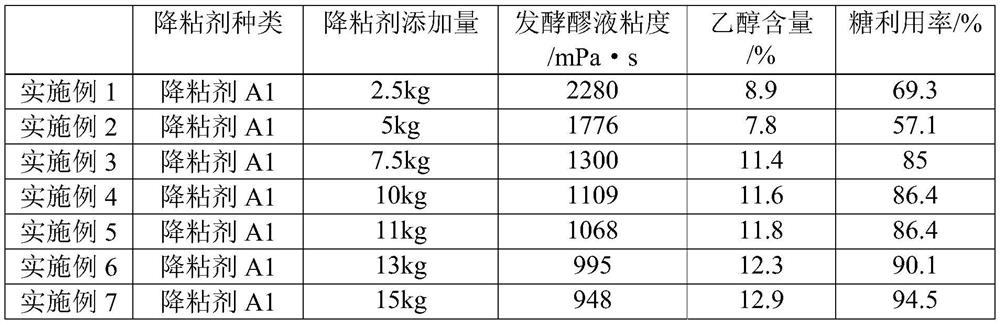

Examples

Embodiment approach

[0041] According to a particularly preferred embodiment of the present invention, the method for preparing the viscosity reducer comprises:

[0042] (1) Dissolving lignin in 0.05-0.5mol / L alkali metal hydroxide solution, then adding formaldehyde until the volume concentration of formaldehyde is 0.2-3%, then reacting at 60-100°C for 30-90min, then adding sulfurous acid with 0.5-5wt% of the total mass of lignin, reacting at 70-90°C for 20-60min, then adjusting the pH of the system to 3-4, then centrifuging, washing, and drying to obtain lignosulfonate;

[0043] (2) Under water-containing conditions, the lignosulfonate and the aluminum source are mixed and dissolved according to a mass ratio of 1-4:1 to obtain a mixed solution;

[0044] (3) In the presence of a noble metal catalyst, the mixed solution is subjected to a catalytic reaction at 40-80° C. for 20-50 minutes to obtain a viscosity reducer solution;

[0045] (4) Drying the viscosity reducer solution to obtain the viscosi...

preparation example 1

[0050] (1) Dissolving lignin in 0.2mol / L sodium hydroxide solution, then adding formaldehyde until the volume concentration of formaldehyde is 1%, and then reacting at 80°C for 50min to obtain a mixed system A;

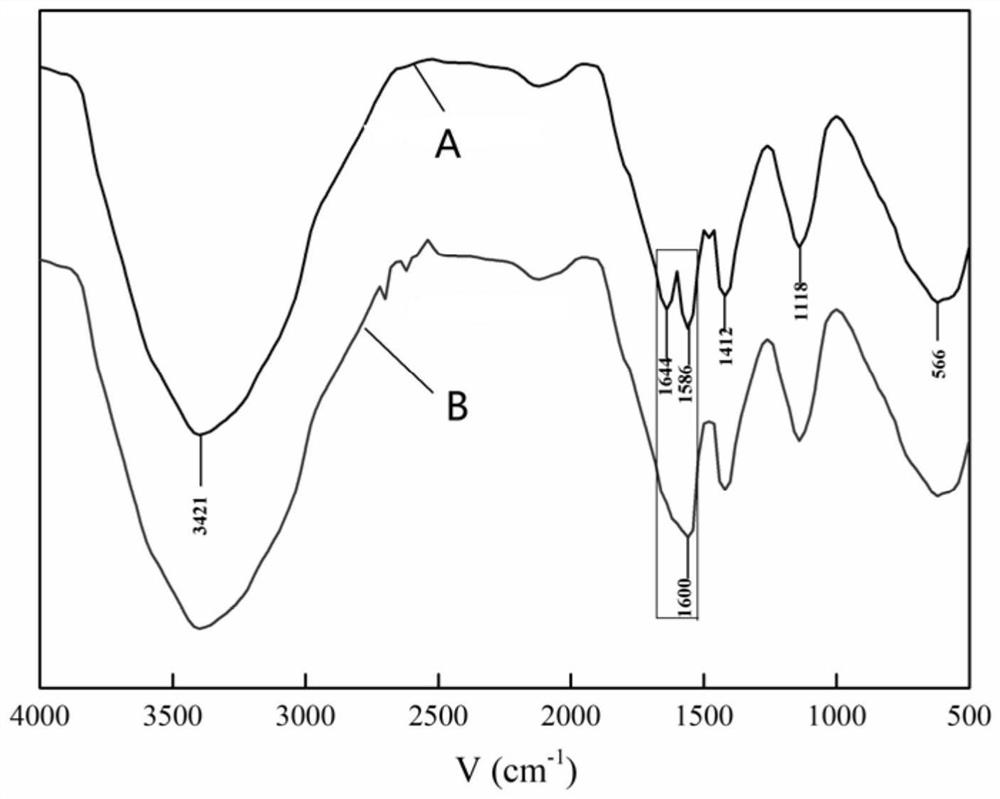

[0051] Add sulfurous acid with a total lignin content of 2wt% to the mixed system A, react at 85°C for 30min, then adjust the pH of the system to 3-4, then centrifuge, wash and dry to obtain sodium lignosulfonate, its infrared spectrum Such as figure 1 shown;

[0052] (2) Sodium lignosulfonate and aluminum chloride are stirred and dissolved in water according to a mass ratio of 1.5:1 to obtain a mixed solution;

[0053] (3) The mixed solution of step (2) is put into a shaking table, and at a shaking speed of the shaking table is 100rpm / min, a platinum calcium carbonate catalyst is added in the mixed solution (the concentration of platinum calcium carbonate in the mixed solution is 1wt%) , catalyzed at 75°C for 40 minutes to obtain a viscosity reducer solution;

[0...

preparation example 2

[0057] According to the method of Example 1, the difference is that the mass ratio of lignosulfonate to alumina is 0.8:1 to obtain viscosity reducer powder A2 (aluminum lignosulfonate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com