a cds/co 3 o 4 Composite material, preparation method and its application in detection of acetone gas under light excitation

A composite material and gas detection technology, which is applied in the direction of analyzing materials, material resistance, and material analysis through electromagnetic means, can solve the problems of high maintenance and use costs, low detection sensitivity, high failure rate, etc., and achieve fast response and high sensitivity , the effect of high sensitivity

Active Publication Date: 2022-05-31

CHINA UNIV OF PETROLEUM (EAST CHINA)

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The methods for detecting acetone content in gas in the prior art include spectral detection method, chromatographic detection method, electrochemical sensor method, etc. However, spectral detection method and chromatographic detection method all need to use special reagents to carry out gas sampling in the environment to be tested, and then Use specific equipment for detection according to specific methods, for example, gas chromatography requires the use of gas chromatographs, and the specific equipment itself is expensive, maintenance and use of these equipment also have very high costs, and the detection sensitivity is low; electrochemical sensors Use ultraviolet light and electric field ionization to decompose acetone in the ambient gas and convert it into carbon monoxide, and then use electrochemical principles to detect the content of carbon monoxide to determine the content of acetone. The electrochemical sensor can only be measured at a single point, with low response and failure. high rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0112] Step 2, transfer the electrospinning precursor prepared in Step 1 to a stainless steel needle equipped with a 22 gauge (inner diameter 0.4 mm)

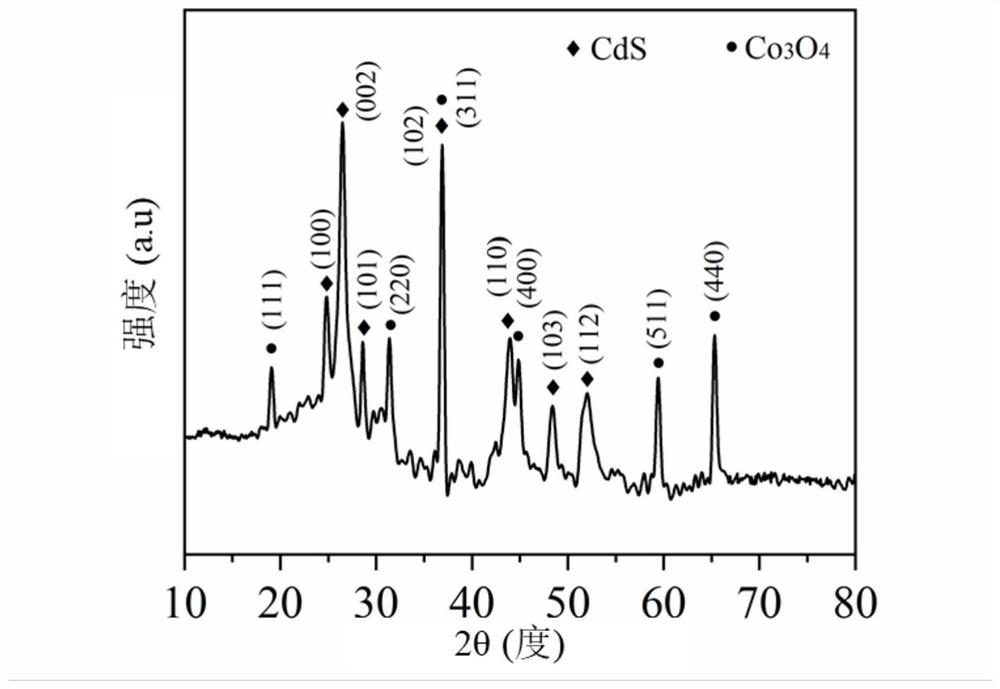

[0118] The results are shown in FIG. 1, and it can be seen from FIG. 1 that at 2θ=31.27°, 36.85°, 44.81°, 59.35° and 65.23°

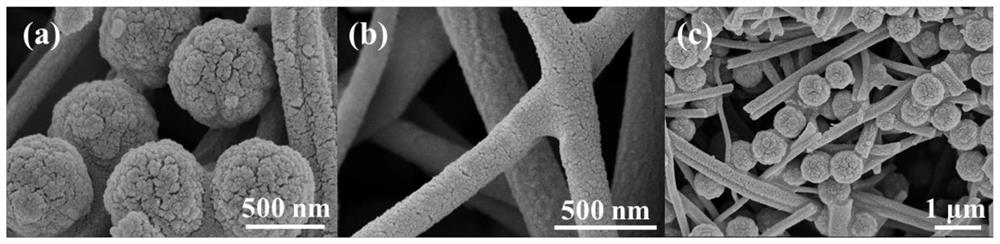

[0122] As shown in Figure 2a, the CdS samples are mostly nanoparticles with a diameter of about 400nm to 500nm;

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

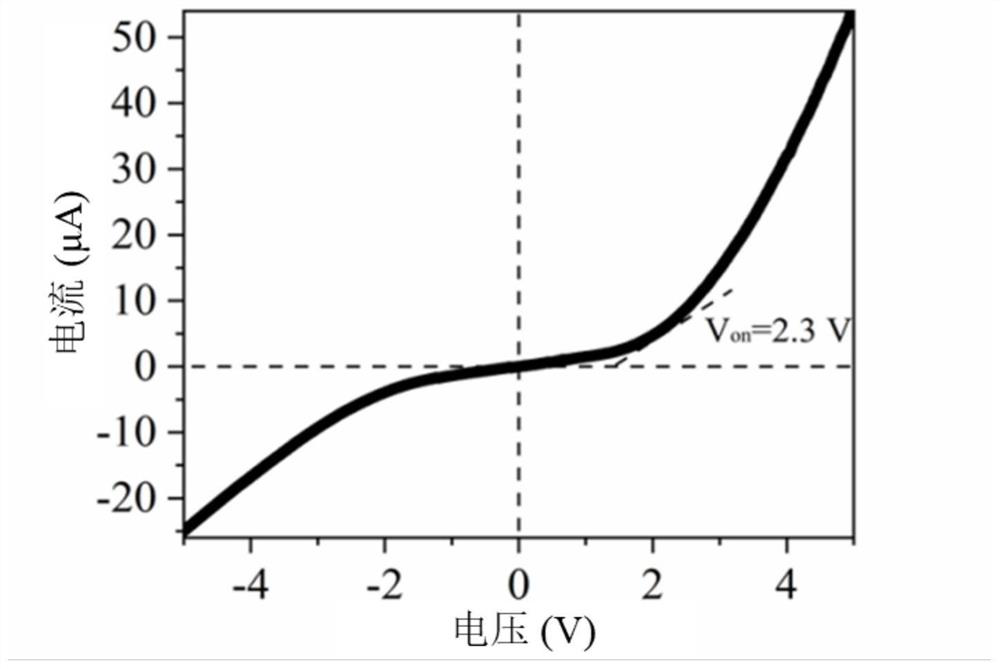

This application discloses a CdS / Co 3 o 4 Composite material and its preparation method and application, the CdS / Co 3 o 4 Composite materials include Co 3 o 4 Nanofibers are well attached to the Co 3 o 4 CdS nanoparticles between nanofibers, where the Co 3 o 4 The diameter of the nanofiber is 200-300nm, the diameter of the CdS nano-particle is 300-400nm, and the CdS / Co 3 o 4 The composite material can be made into a gas sensor, an acetone gas sensor, and a light-excited gas-sensing test platform. The CdS / Co 3 o 4 Composite materials and their products can detect acetone gas at room temperature (25°C), and have the advantages of high sensitivity, short response recovery time, good selectivity, etc., and a wide detection range, effectively solving the problem of traditional acetone gas sensors at low temperature and low temperature. The problem of poor gas sensitivity characteristics in the gas concentration area.

Description

A CdS / Co 3 O 4 Composite material, preparation method and effect on acetone gas under light excitation Applications in Body Detection technical field The application belongs to semiconductor oxide application field, particularly a kind of CdS / Co 3 O 4 Composite material, preparation method and its application in the detection of acetone gas under light excitation. Background technique Acetone is a kind of colorless, flammable, volatile compound, is widely used in explosives, paint and plastic field, has It has a pungent odor, and long-term exposure to acetone vapor will seriously endanger human health, causing eye irritation, dizziness, fatigue, Symptoms such as bronchitis and, in severe cases, damage to organs. On the other hand, with the continuous development of medical technology, in recent years, exhalation The detection of the biomarker acetone in gas has become a new method for non-invasive diagnosis of diabetes in medicine. Currently in th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G11/02C01G51/04G01N27/12

CPCC01G51/04C01G11/02G01N27/127C01P2002/72C01P2004/03C01P2004/62C01P2004/61Y02A50/20

Inventor 张冬至郭敬宇李停停

Owner CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com