Hollow stabilizer bar conveying system

A conveying system and stabilizer bar technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, large waist injury, low work efficiency, etc., to save manpower and material resources, smooth movement, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

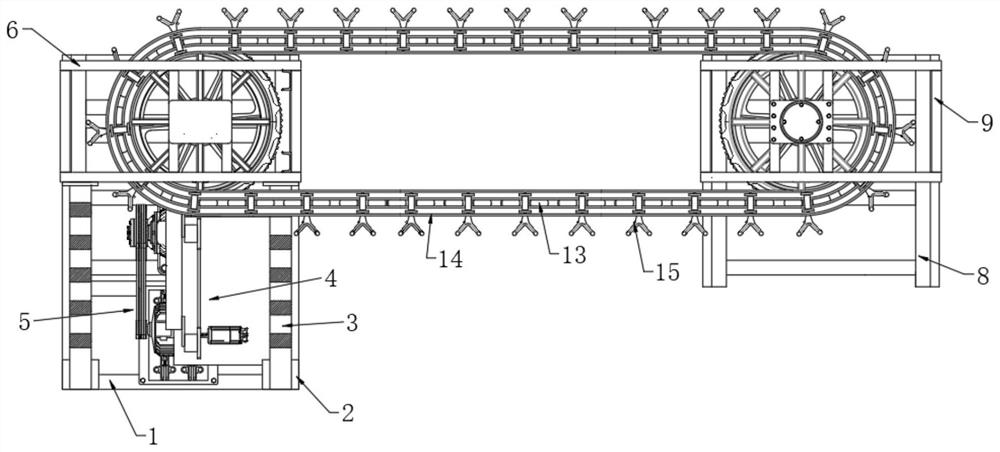

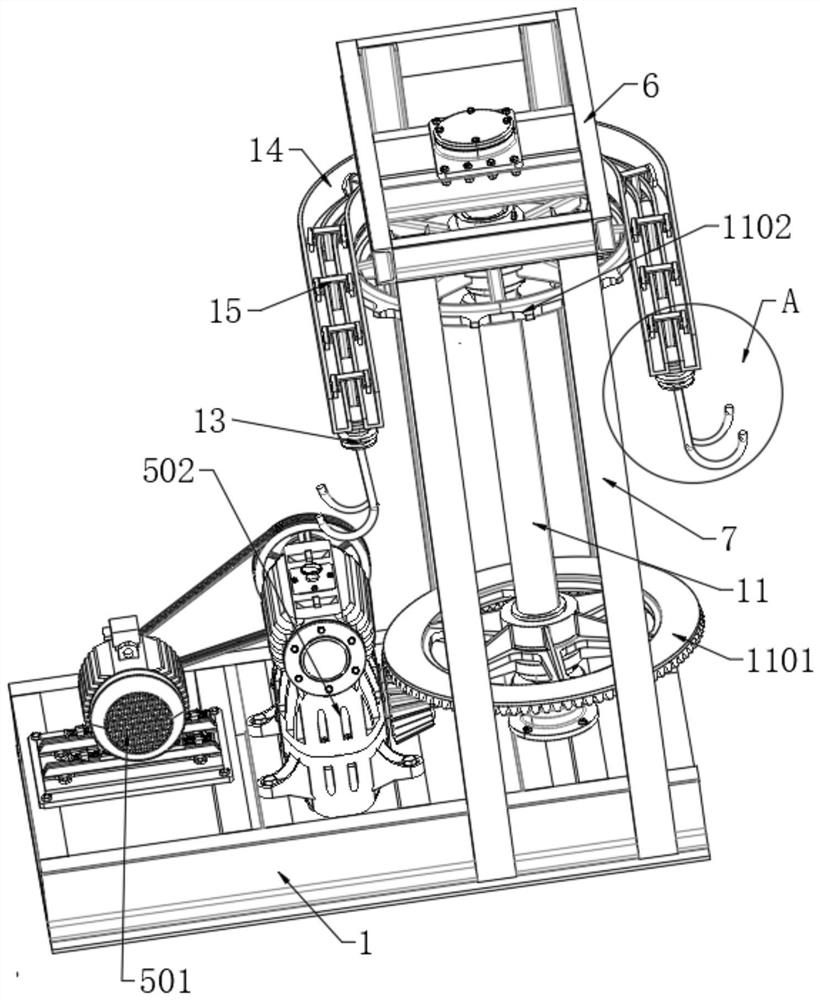

[0039] Please refer to the attached Figure 1-6 , a hollow stabilizer bar delivery system comprising:

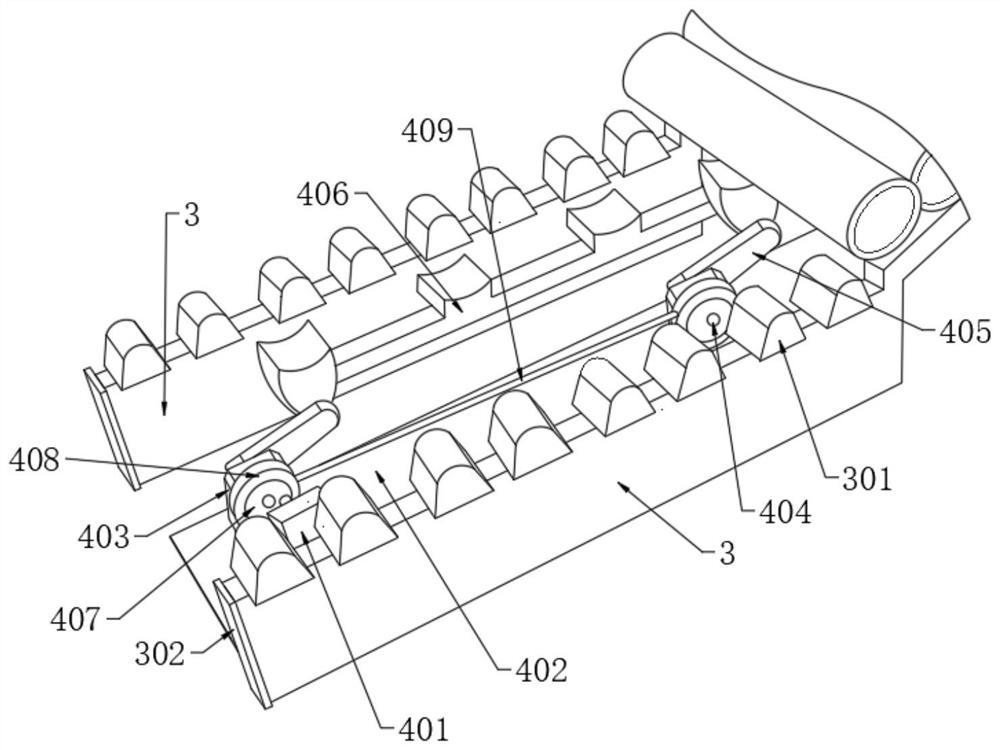

[0040] The first base 1, a pair of first supporting legs 2 are vertically welded on one side of the first base 1, and a pair of first supporting legs 2 are welded with a feeding plate 3, and a pair of feeding plates 3 are rotationally connected with a second A driving device 4 .

[0041]Further, the set first base 1 is in the shape of a rectangular frame, which is stable and saves the use of materials. A layer of rubber pad is provided on the contact surface between the first base 1 and the ground to play the role of anti-slip and anti-friction. Prevent the first base 1 made of metal from being directly contacted with the ground to cause abrasion.

[0042] The second driving device 5 is formed on the upper surface of the first base 1 .

[0043] Further, a connecting plate is horizontally connected to the first base 1, and the second driving device 5 is screwed on the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com