Novel blade type demister

A vane type, mist eliminator technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as reducing separation efficiency and separation effect, reducing steam turbine power generation, and steam turbine mechanical damage, etc. The effect of small airflow pressure drop, increasing effective separation area, and no energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

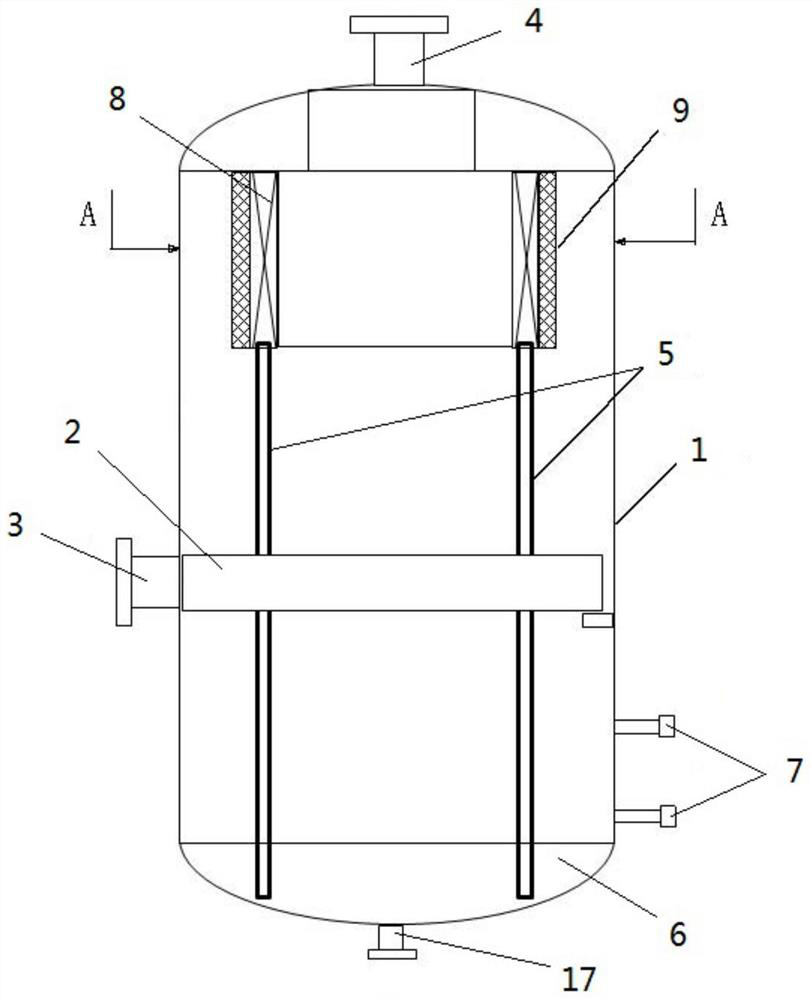

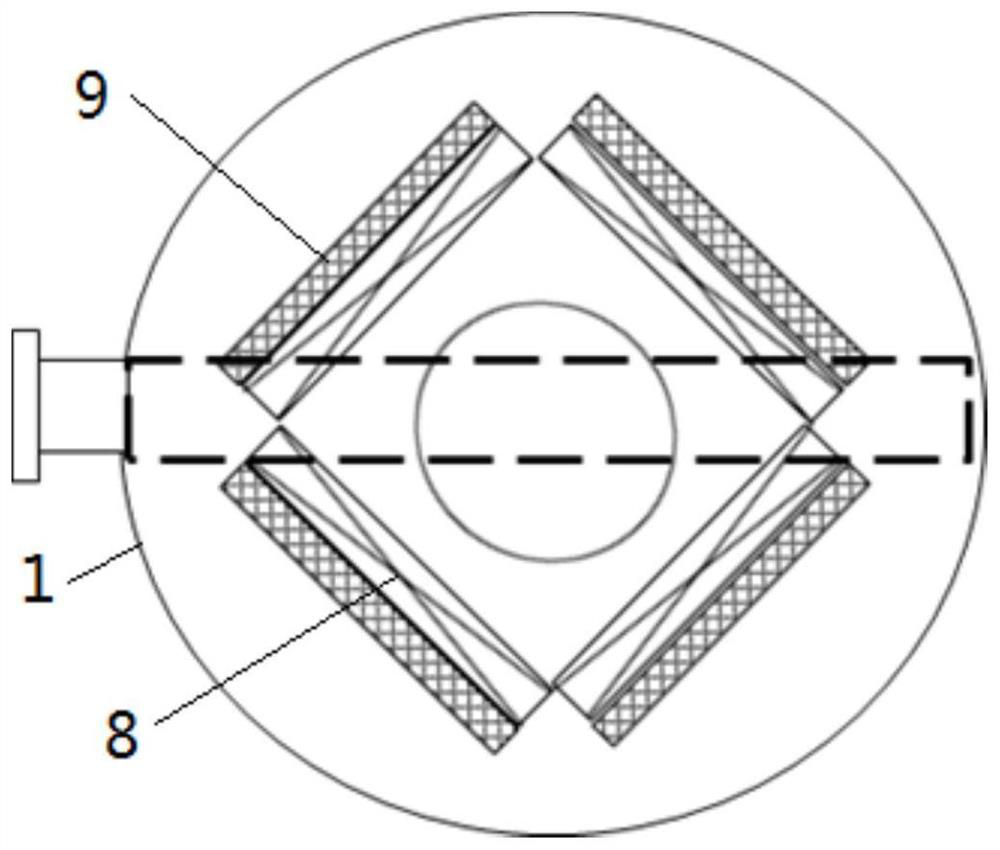

[0032] Such as figure 1 As shown, a new vane type demister includes a housing 1, a pre-separator 2 and a separator, one side of the housing 1 is provided with an air inlet 3, and the top of the housing 1 is provided with an air outlet 4, and the air inlet Port 3 communicates with the pre-separator 2. The pre-separator 2 is arranged in the horizontal direction of the housing 1. A separator is located vertically above the pre-separator 2 in the housing 1. The air outlet of the pre-separator 2 corresponds to the air inlet of the separator. , the air outlet at the top of the separator corresponds to the air outlet 4, the liquid outlet at the bottom of the separator is connected to the condensate discharge pipe 5, the inner bottom of the shell 1 is provided with a condensate tank 6, and the condensate discharge pipe 5 extends into the condensate tank 6 , The bottom of the condensate tank 6 is provided with a condensate discharge outlet 17 .

[0033] Specifically, the separator inc...

Embodiment 2

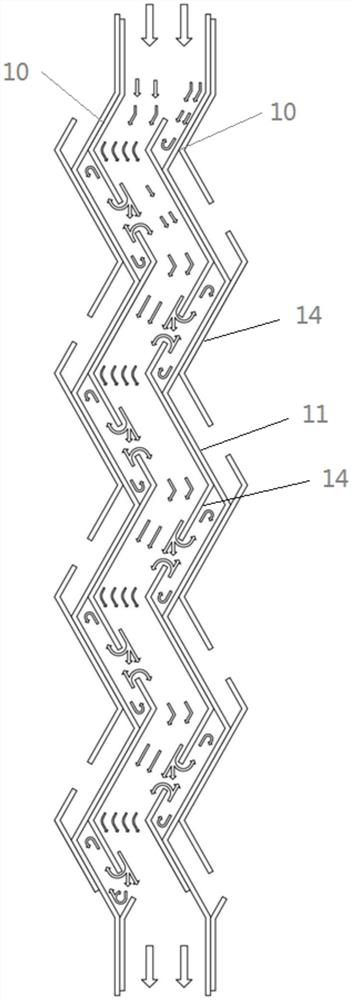

[0053] The difference between this embodiment and Embodiment 1 is that the structure of the blade group is as follows: Figure 5 As shown, two other composite blade sandwich types of blades 10 are shown.

[0054] Under different working conditions and different material media, different blade types can be selected, which are also composite blade interlayers, to achieve a higher capacity to handle liquid loads.

[0055] The specific implementation principle of the present invention is: in the present invention, during the working process of the mist eliminator, the gas and the condensate flow separately, which avoids the situation that the gas entrains the separated condensate to form a secondary entrainment, and effectively increases the separation efficiency .

[0056] In the present invention, the blades 10 are designed according to aerodynamic optimization. The blades 10 use the inertia difference between the air flow and the contained fine liquid droplets to effectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com