An ultrasonic nebulizer

An ultrasonic and nebulizer technology, applied in the field of ultrasonic nebulizers, can solve the problems of e-liquid consumption, ultrasonic atomizing chips being easily soaked in e-liquid, and ultrasonic atomizing chips, so as to avoid local dry burning and ensure The effect of ultrasonic atomization efficiency and stable smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

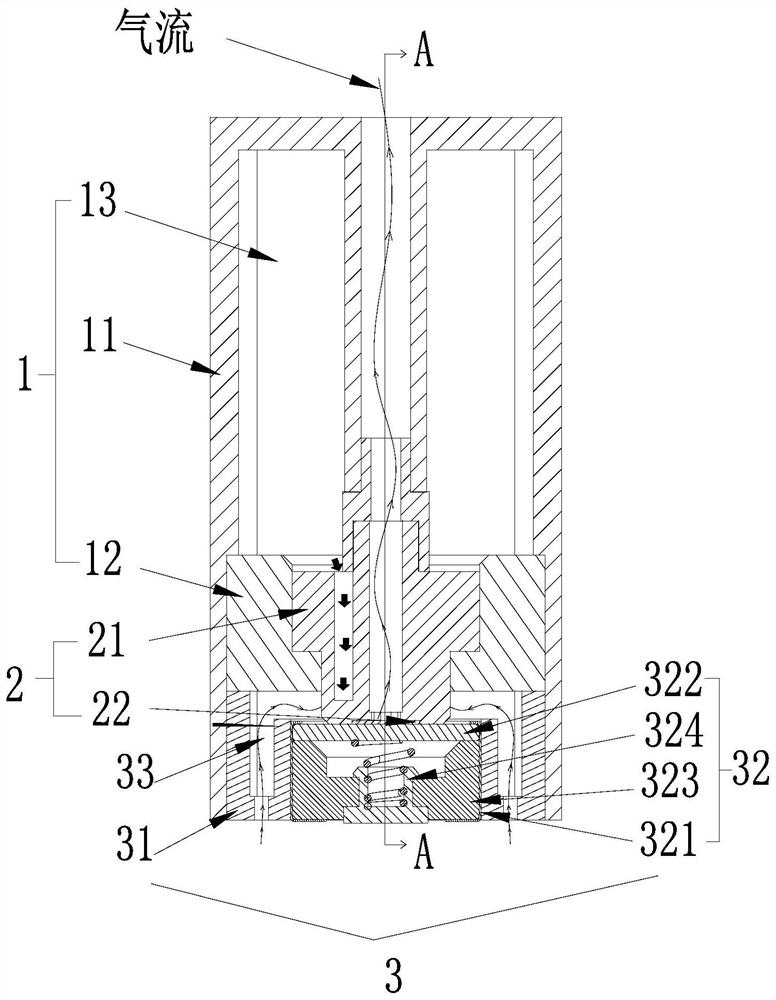

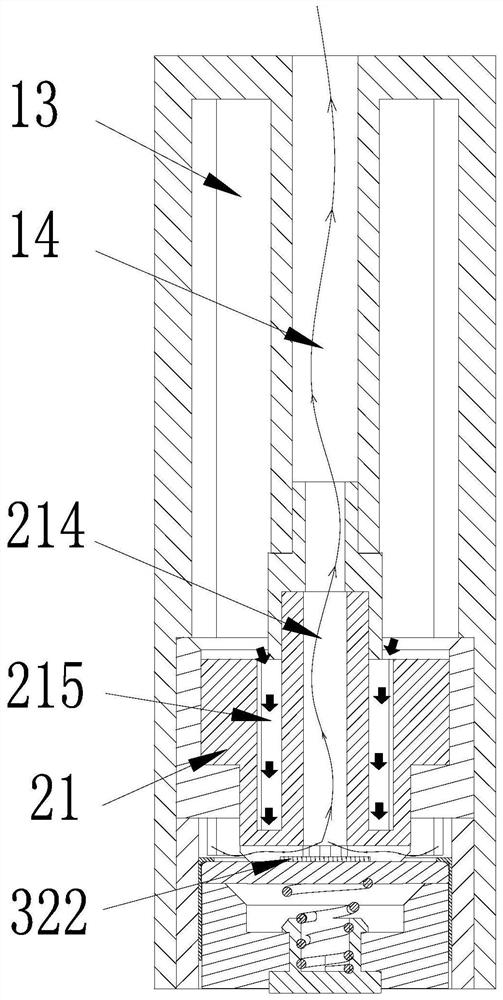

[0033] like figure 1 - Image 6 As shown, the ultrasonic atomizer of this embodiment includes an oil storage assembly 1 , an oil guide assembly 2 and an atomization assembly 3 , and the oil guide assembly 2 and the atomization assembly 3 are sequentially installed at the bottom of the oil storage assembly 1 .

[0034] The oil storage assembly 1 includes a housing 11 and a plug body 12 that are joined to each other, and an oil reservoir 13 is formed inside the housing 11 and the plug body 12 after the housing 11 and the plug body 12 are joined. The plug body 12 is preferably an elastic silicone plug.

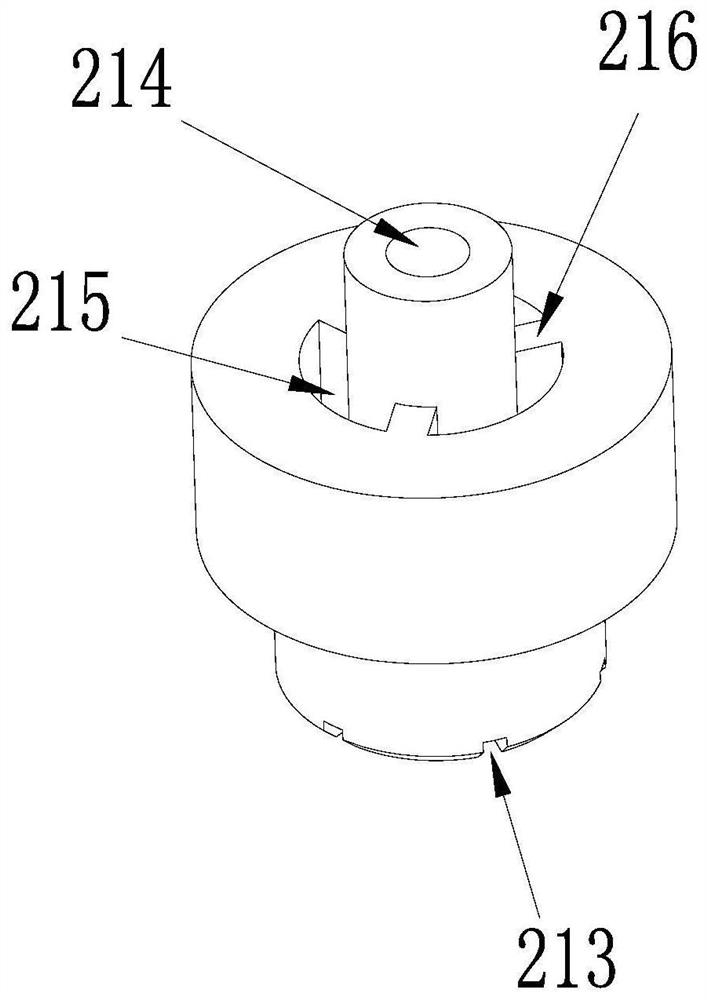

[0035] The oil guide assembly 2 includes an oil guide ceramic 21 and an oil storage cotton 22 . The thickness of the oil storage cotton 22 is 0.1-1.0 mm.

[0036] A placement groove 211 is provided in the middle of the lower surface of the oil-conducting ceramic 21,

[0037]The size of the placement groove 211 is consistent with the size of the oil storage cotton 22, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com