A buck-boost converter control circuit with mode switching

A buck-boost converter and control circuit technology, applied in control/regulation systems, DC power input conversion to DC power output, instruments, etc., can solve problems such as uncertain working modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0074] The specific details in the embodiments described below, such as the specific circuit structure in the embodiments and the specific parameters of these circuit elements, are used to provide a better understanding of the embodiments of the present invention, wherein the first and second are used to distinguish and Not intended to be limiting, such as the first state and second state of a signal. It will be understood by those skilled in the art that embodiments of the present invention may be practiced even without certain details or other combinations of methods, elements, materials, and the like.

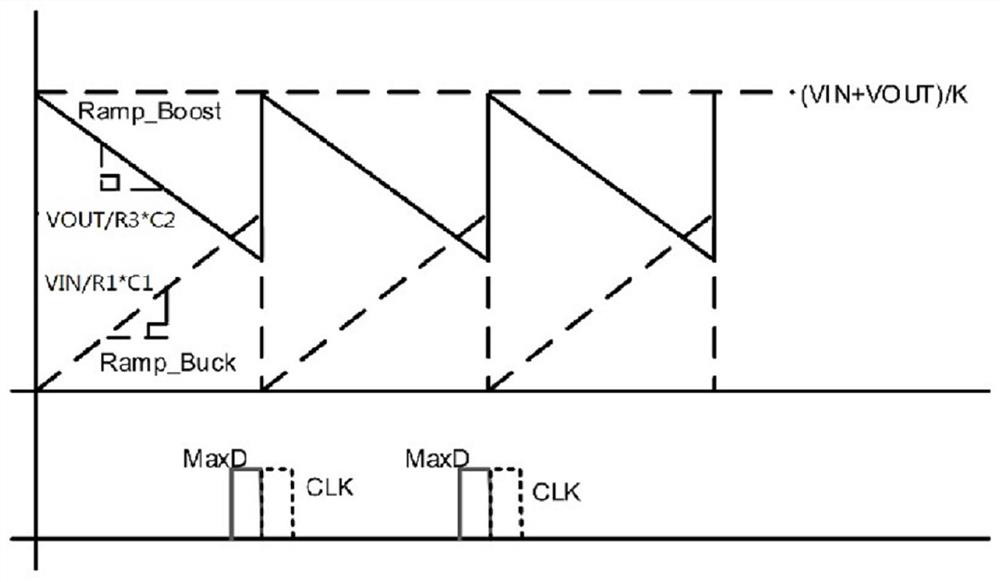

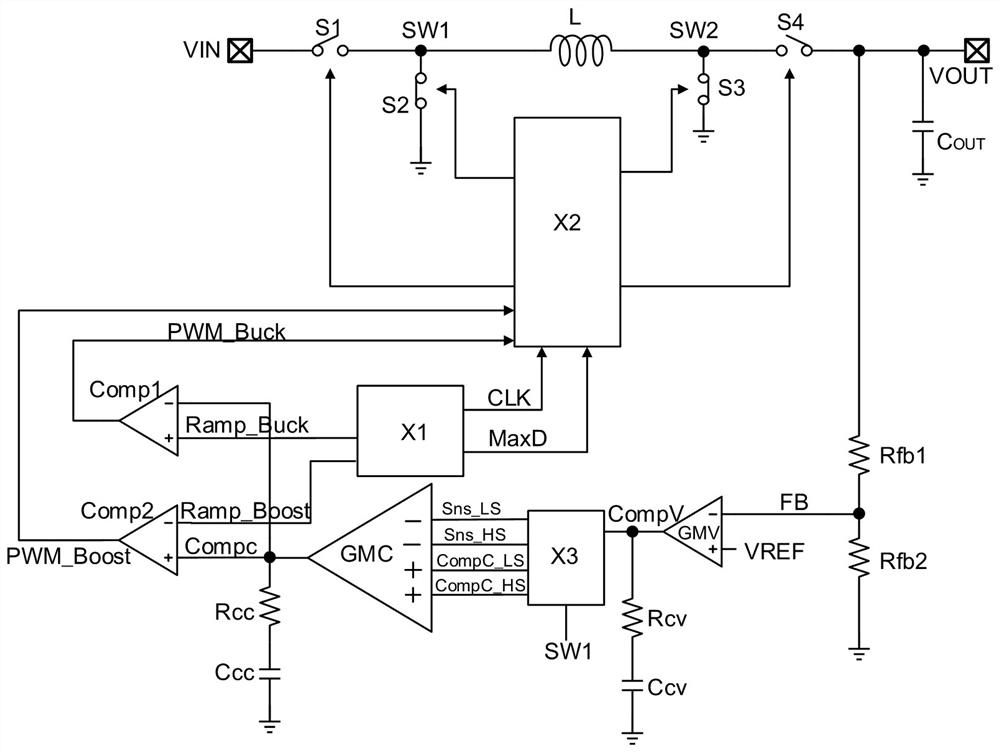

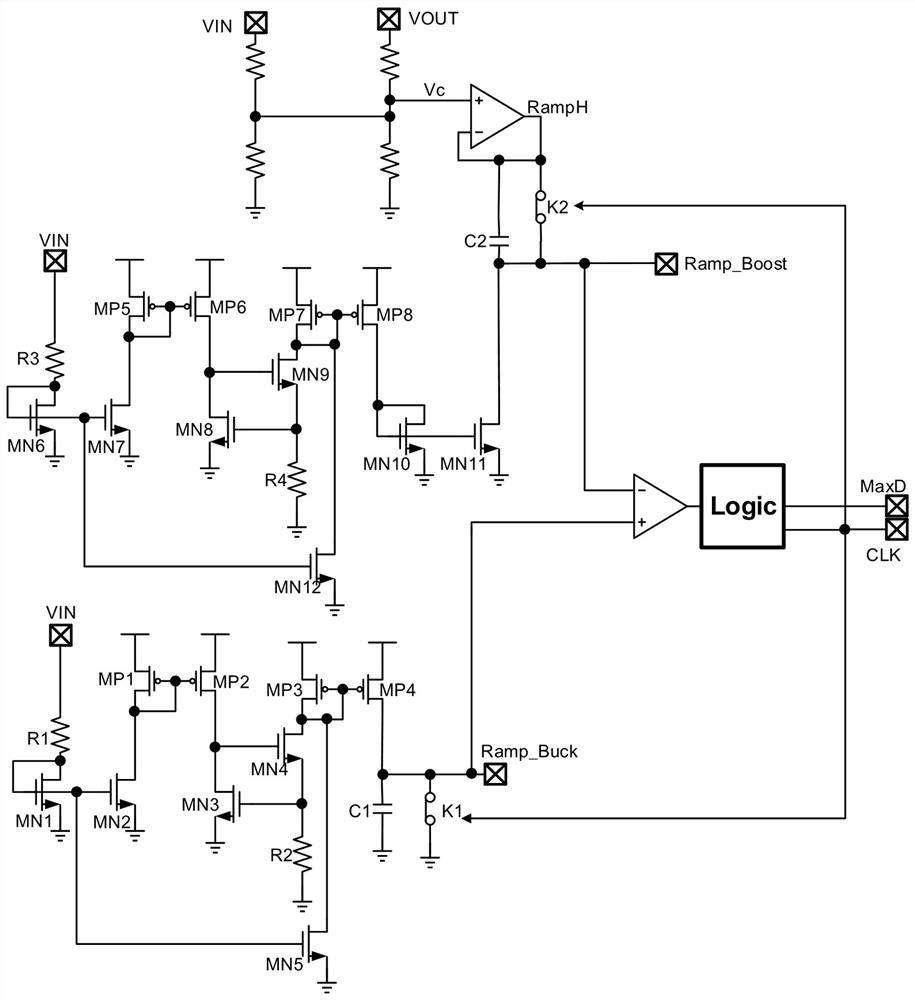

[0075] like figure 1 As shown, the buck-boost converter includes a first switch tube S1, a second switch tube S2, a third switch tube S3, a fourth switch tube S4 and an inductor L, and the first switch tube S1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com