Polymer solid electrolyte membrane and its preparation method and all-solid-state battery

A technology of solid electrolyte membrane and polymer, applied in the direction of nonaqueous electrolyte batteries, solid electrolytes, nonaqueous electrolytes, etc., can solve the problem of low room temperature conductivity, achieve high room temperature ion conductivity, improve safety and service life, The effect of improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

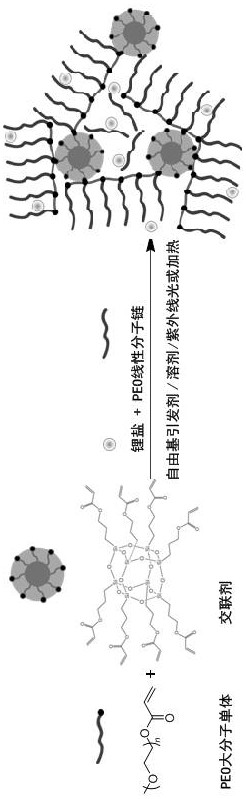

[0043] A polymer solid electrolyte membrane, the preparation method of which comprises the steps of:

[0044] (1) Take 440.4 mg of methoxypolyethylene glycol acrylate (PEO macromer) with a molecular weight of 750 Da, 145.2 mg of 8-acrylic cage polysilsesquioxane (crosslinking agent), 4.4 mg 2-Hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone (free radical initiator), 878.4 mg polyethylene glycol methyl ether with a molecular weight of 750 Da (PEO linear molecular chain), 432.0 mg LiN(SO 2 CF 3 ) 2 (Lithium salt) into a reaction flask, add 2 ml of tetrahydrofuran to dissolve, and stir for 30 minutes under the protection of an inert atmosphere to mix well.

[0045] (2) Take 2.5 ml of the mixture prepared in step (1) and spread it evenly to an area of 100 cm 2 On the polytetrafluoroethylene mold, use ultraviolet light to irradiate the surface of the mold coated with the reaction solution, irradiate for 20 minutes, let it stand for 8 hours, and dry it in vacuum at 25 ° C fo...

Embodiment 2

[0047] A polymer solid electrolyte membrane, the preparation method of which comprises the steps of:

[0048] (1) Take 110.1 mg of methoxypolyethylene glycol acrylate (PEO macromer) with a molecular weight of 750 Da, 36.3 mg of 8-acrylic cage polysilsesquioxane (crosslinking agent), 1.1 mg 2-Hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone (free radical initiator), 219.6 mg polyethylene glycol methyl ether with a molecular weight of 750 Da (PEO linear molecular chain), 108.0 mg LiN(SO 2 CF 3 ) 2 (Lithium salt) in a reaction bottle, add 500 μl tetrahydrofuran to dissolve, and stir for 30 minutes under the protection of an inert atmosphere to mix well.

[0049] (2) Take 50 μl of the mixture prepared in step (1) and spread evenly to an area of 2 cm 2 On the surface of the lithium metal negative electrode, use ultraviolet light to irradiate the surface of the lithium metal sheet coated with the reaction solution, irradiate for 20 minutes, let it stand for 8 hours, and dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com