Intelligent control system for forging and pressing line

An intelligent control system and forging line technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as equipment instability, reduce processing costs, improve efficiency, and achieve the effect of visual management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

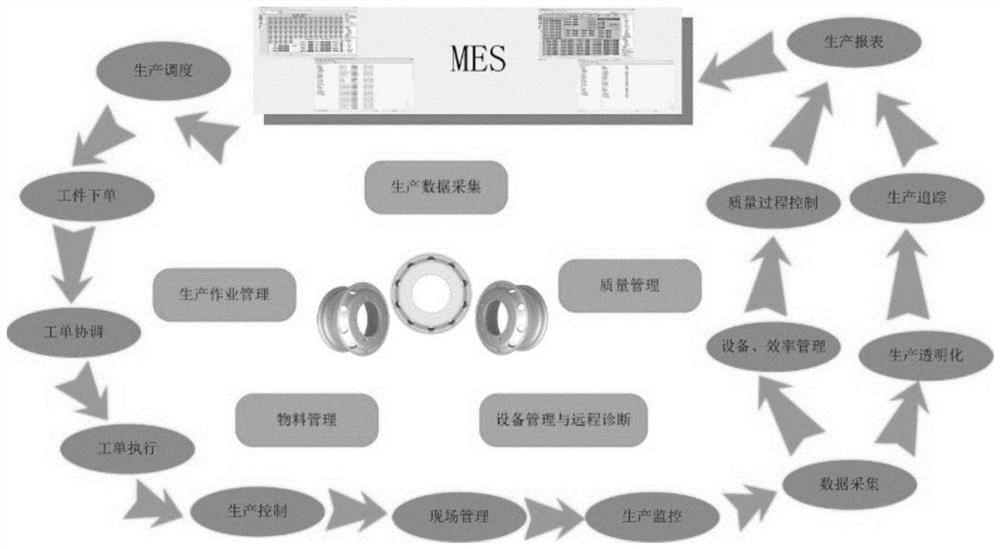

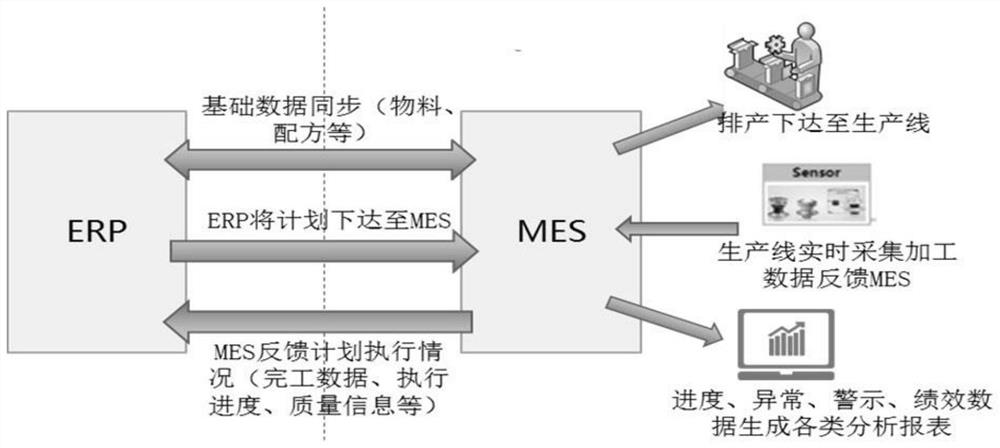

[0033] The present disclosure provides an intelligent control system for a forging line. The above-mentioned intelligent control system for a forging line can realize the formulation of the process parameters of the forging line, optimize the control of the production operation of the forging line, realize the visual management of production, and solve the management of the process implementation process of the forging line , and then improve the pressure accuracy and speed control, etc., which can greatly improve the efficiency of the forging line, increase the yield, and reduce the processing cost.

[0034] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0035] In an embodiment of the present disclosure, an intelligent control system for a forging line is provided, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com