Split type thrust tool

A split and thrust technology, which is applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problem that the product cannot be fully stressed, and achieve accurate and consistent force application and uniform force , the effect of pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

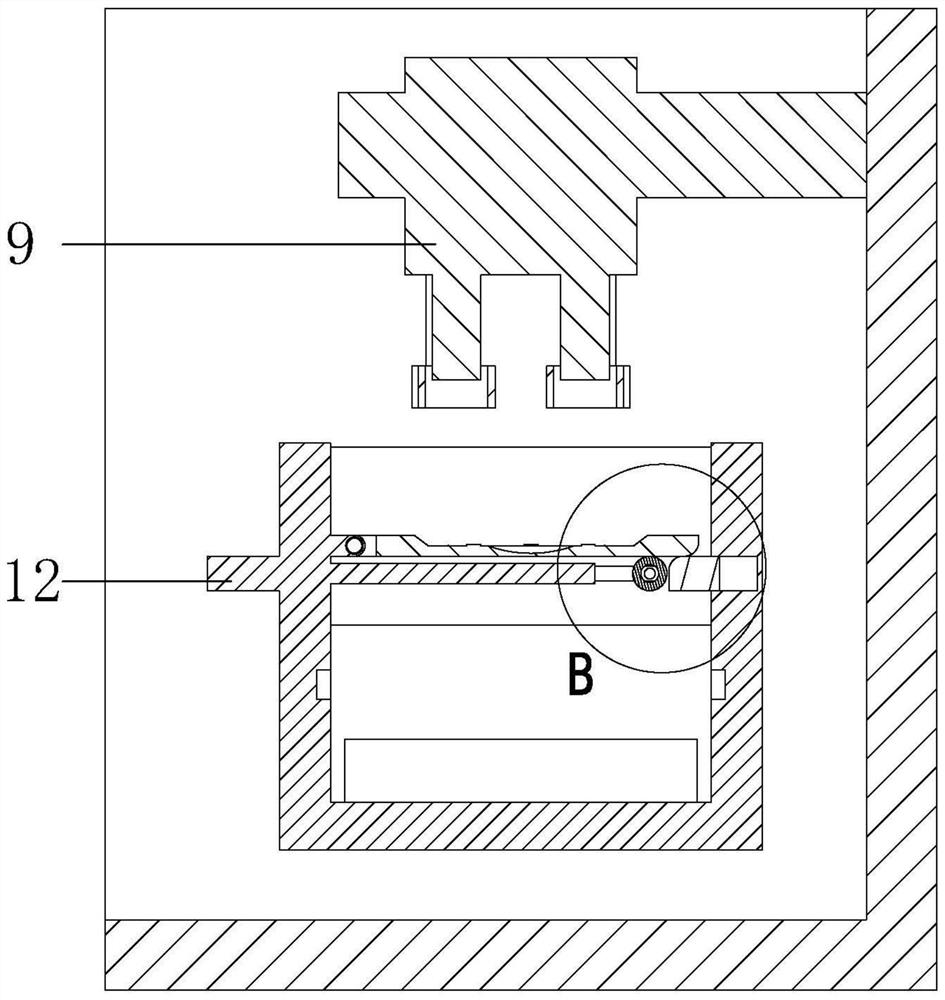

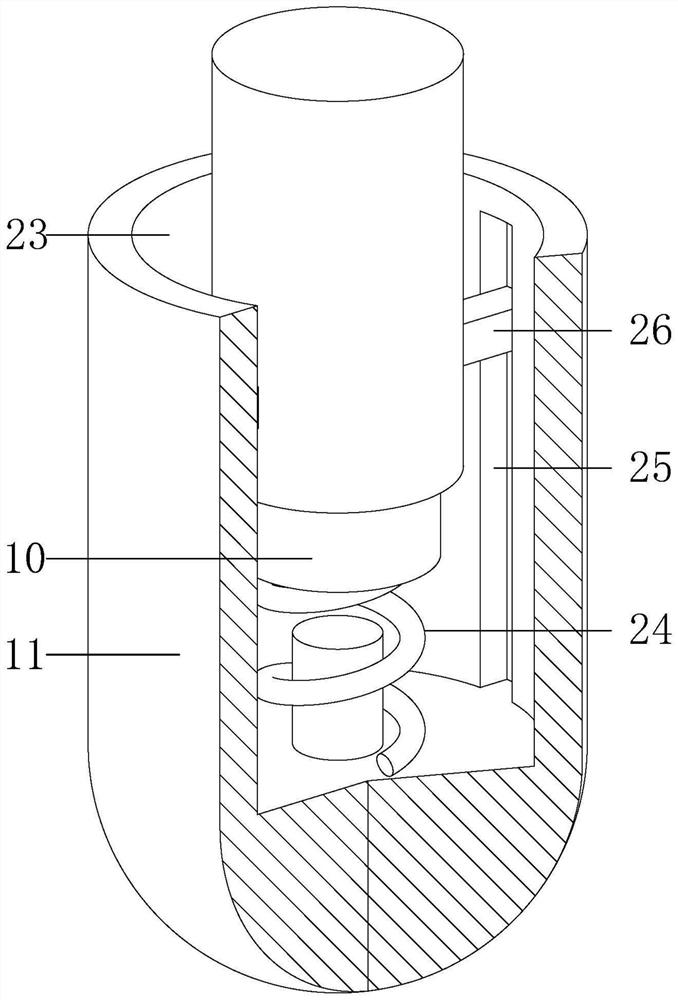

[0027] Such as figure 1 In the shown embodiment, a split-type thrust tooling includes a frame 1, a placement table 2, a conveyor belt 3, a slide plate 4 and several split-type cylinders 5, and the placement table 2 is horizontally arranged on the inner bottom of the frame 1 , the top surface of the placement platform 2 is provided with a transmission slot 6 that runs through the left and right sides, the right end of the conveyor belt 3 passes through the left side wall of the frame 1 and is placed on the left side of the placement platform 2 and corresponds to the transmission slot 6, and the slide plate 4 The top of the placing table 2 is connected with the frame 1, and the split cylinders 5 are evenly arranged and distributed from left to right on the slide plate 4. The thrust assembly 7 is arranged on the split cylinder 5, and several split...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com