Engine lubricating oil liquid level monitoring and early warning device

A technology of early warning device and liquid level monitoring, applied in the direction of engine lubrication, lubrication indicating device, engine components, etc., can solve the problems of time-consuming inspection, low efficiency, loss of lubricating oil, etc., and achieve convenient installation and operation, compact structure, and integration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with accompanying drawing and specific embodiment, the present invention is described:

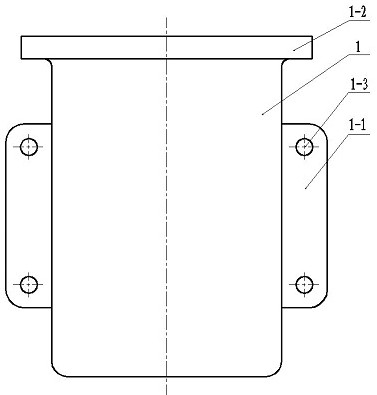

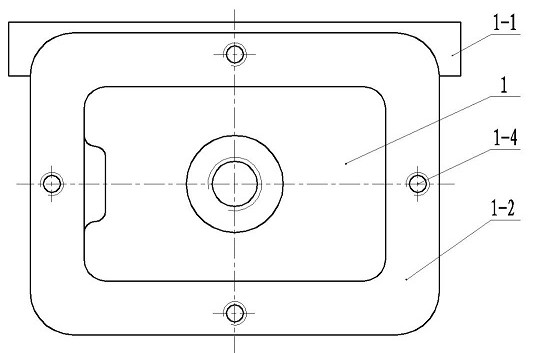

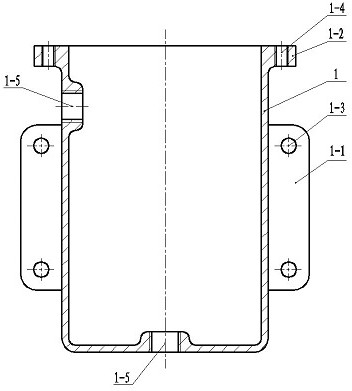

[0027] Such as Figure 11 As shown, an engine lubricating oil liquid level monitoring and early warning device mainly includes: housing 1, gasket 2, end cover 3, oil dipstick 4, sleeve I5, sleeve II6, liquid level switch I7, liquid level switch II8, Oil pan 9, sound and light alarm 10, stuffing box 11, bolt I12, O-ring 13, lubricating oil pipe I14, bolt II15, lubricating oil pipe II16. The pressure test sleeve is as figure 1 The main body shown is a hollow cuboid, and the back is designed with a rectangular flange I1-1, and the rectangular flange I1-1 is designed with four circular through holes I1-3, which are used to install the housing 1 to the oil pan 9 on, such as figure 2 The shown top is designed with a rectangular flange Ⅱ1-2, and the rectangular flange Ⅱ1-2 is designed with four threaded through holes Ⅰ1-4 for the installation of the end cover 3, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com