Notched steel beam with flange embedded in floor slab and floor slab structure and construction method

A floor and flange technology, which is applied in the field of notched steel beams and floor structures and construction, can solve the problems of reduced space utilization rate, low space utilization rate, multiple indoor spaces, etc., to improve space utilization rate, improve quality, and improve resistance The effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

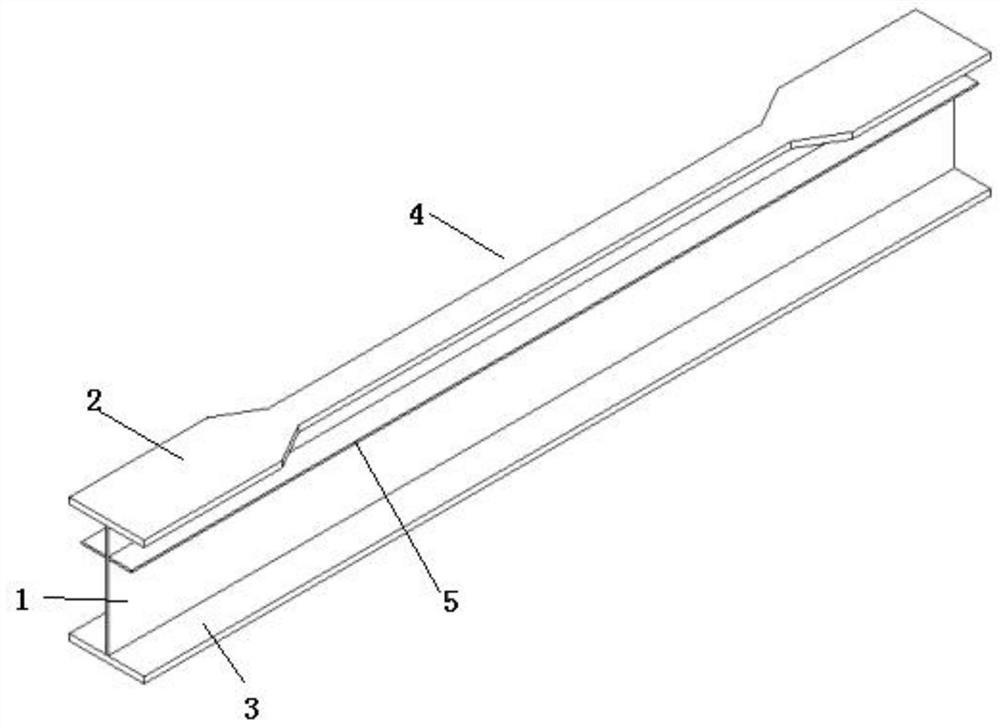

[0034] Example 1. Notched steel beams whose flanges are embedded in the slab, constituted as figure 1 , including a web 1, the upper and lower ends of the web 1 are respectively provided with an upper flange 2 and a lower flange 3; the upper flange 2 is provided with a gap 4.

[0035] The gap is used for the base plate of the laminated plate to be in place, and the length of the gap is greater than the width of the base plate of the laminated plate.

[0036] The notch 4 is located in the middle of the upper flange 2 .

[0037] Notches 4 are provided on one or both sides of the upper flange 2 .

[0038] The web 1 is also provided with a supporting plate 5 between the upper flange 2 and the lower flange 3 . The gap between the carrier plate and the upper flange is used for the installation of the plywood bottom plate.

[0039] The web 1 is also provided with openings for pipelines to pass through.

[0040] The web 1 and / or the upper flange 2 are also provided with pegs, she...

Embodiment 2

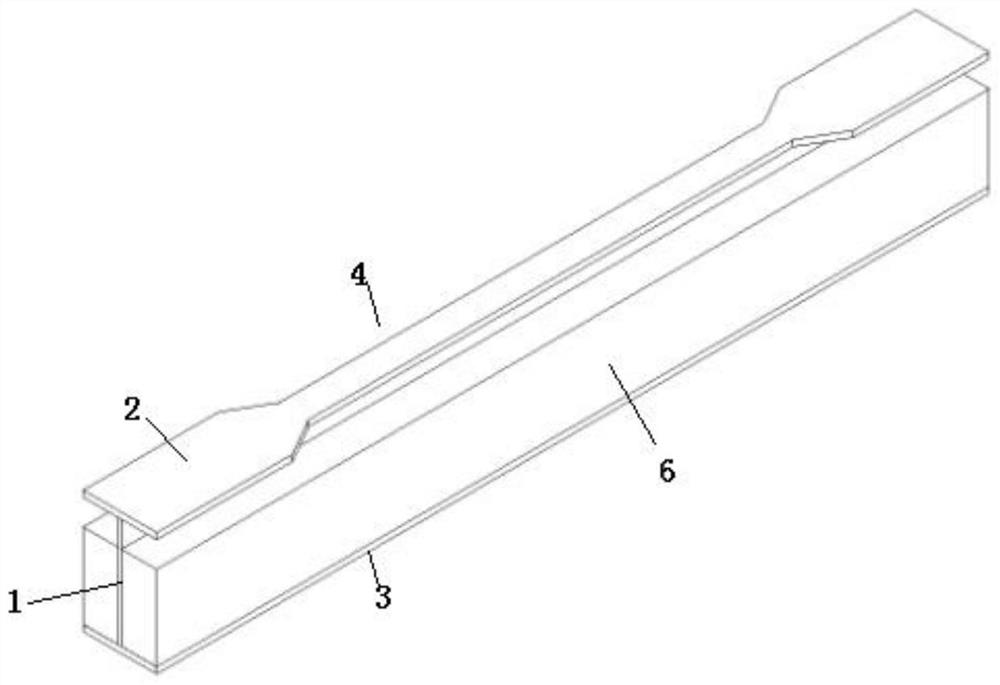

[0055] Example 2. Notched steel beams whose flanges are embedded in the slab, constituted as figure 2 As shown, including the web 1 , the upper and lower ends of the web 1 are respectively provided with an upper flange 2 and a lower flange 3 ; the upper flange 2 is provided with a gap 4 .

[0056] The gap is used for the base plate of the laminated plate to be in place, and the length of the gap is greater than the width of the base plate of the laminated plate.

[0057] The notch 4 is located in the middle of the upper flange 2 .

[0058] Notches 4 are provided on one or both sides of the upper flange 2 .

[0059] A concrete bracket 6 located above the lower flange 3 is also provided on the web 1 . The gap between the concrete support 6 and the upper flange is used to support the laminated slab bottom plate.

[0060] The web 1 is also provided with openings for pipelines to pass through.

[0061] The web 1 and / or the upper flange 2 are also provided with pegs, shear keys,...

Embodiment 3

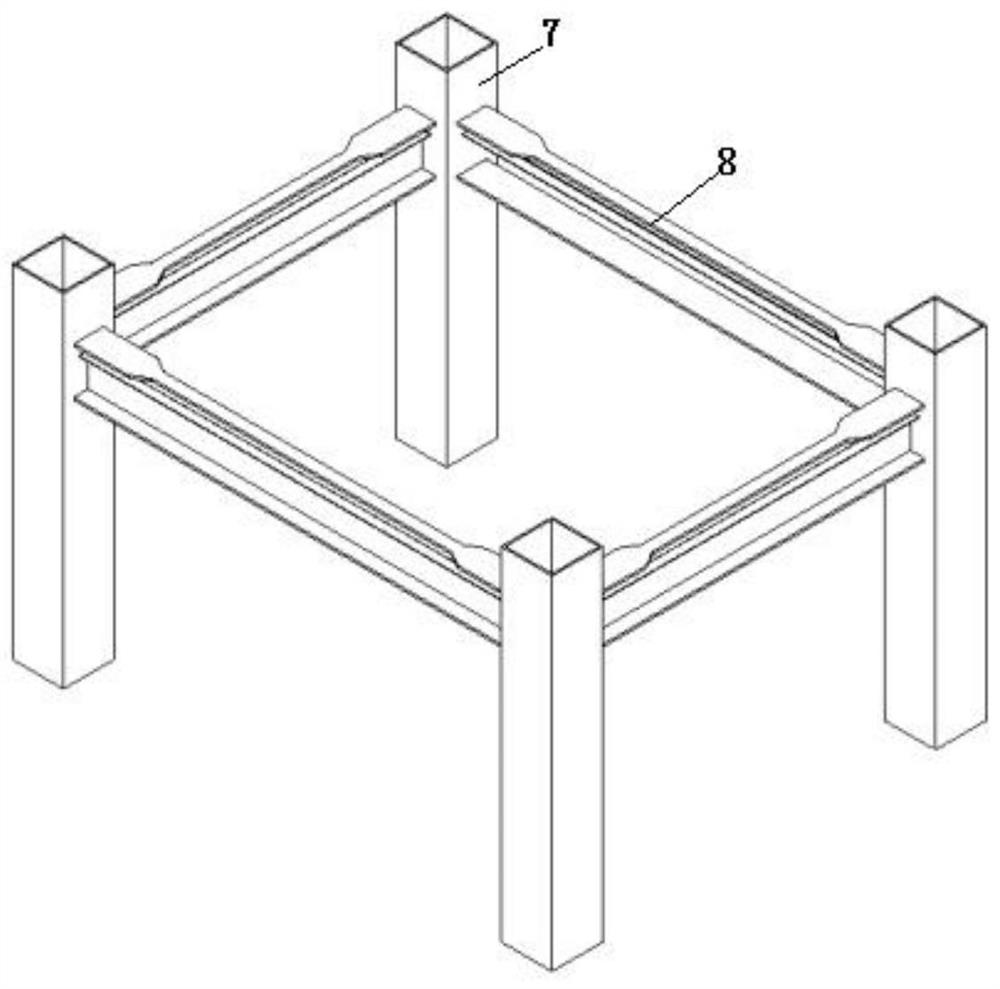

[0075] Example 3. Notched steel beams whose flanges are embedded in the slab, constituted as Figure 10 As shown, including the web 1 , the upper and lower ends of the web 1 are respectively provided with an upper flange 2 and a lower flange 3 ; the upper flange 2 is provided with a gap 4 .

[0076] Notches 4 are provided on one or both sides of the upper flange 2 .

[0077] The gap is used for the base plate of the laminated plate to be in place, and the length of the gap is greater than the width of the base plate of the laminated plate.

[0078] When the beam height is reduced to the same height as the floor, the lower flange of the steel beam directly acts as a support for the floor.

[0079] The notch 4 is located in the middle of the upper flange 2 .

[0080] The web 1 is also provided with openings for pipelines to pass through.

[0081] The web 1 and / or the upper flange 2 are also provided with pegs, shear keys, indentations and / or protrusions.

[0082] A floor st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com