Heat-resistant and fireproof building fire-fighting floor slab

A fire protection and construction technology, applied in the field of floor fire protection, can solve the problems of weak fire protection measures and unsatisfactory fire extinguishing effect, and achieve the effect of reducing losses and hazards and improving the flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

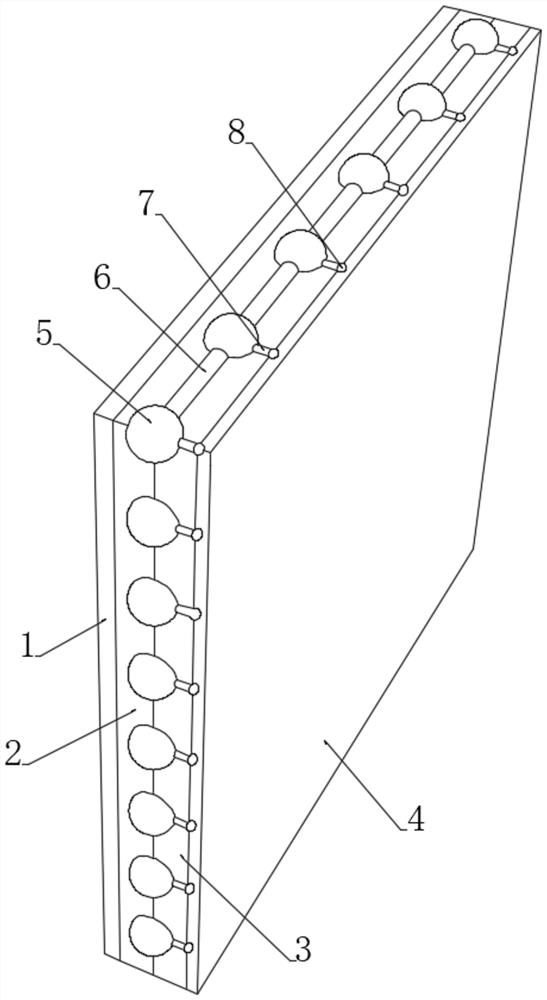

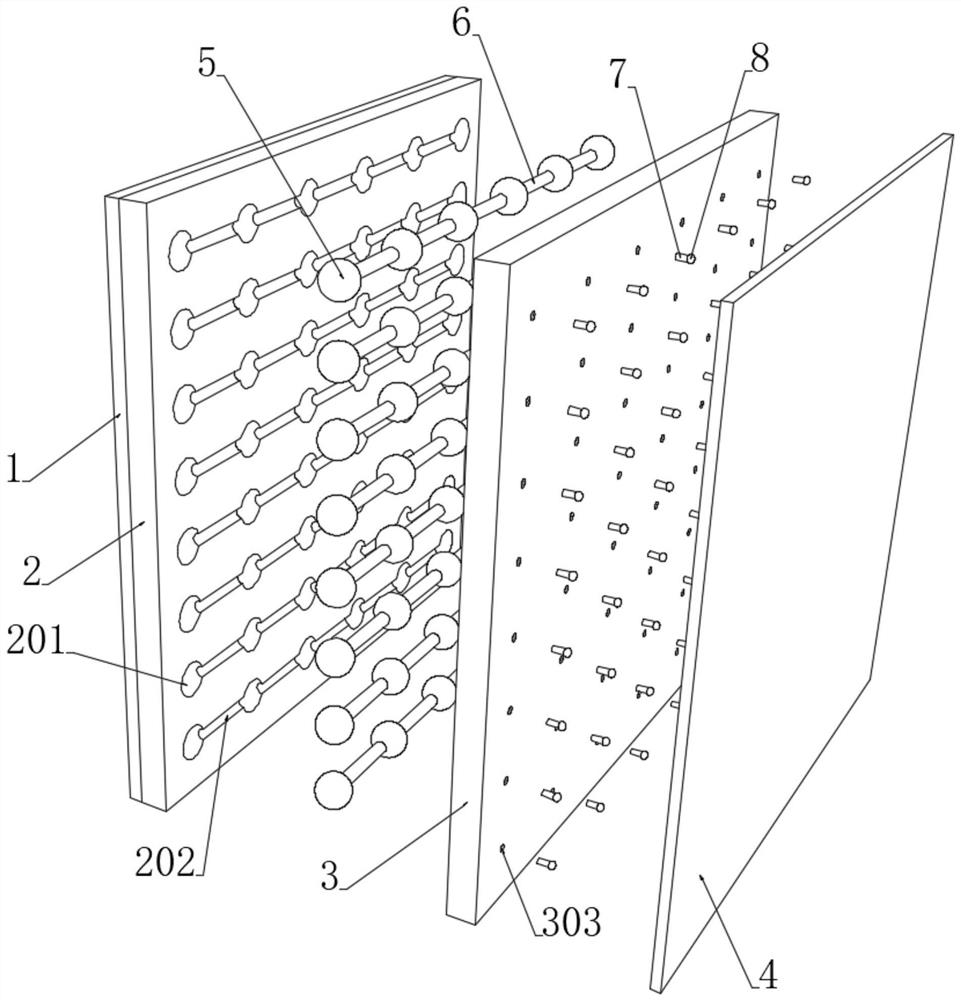

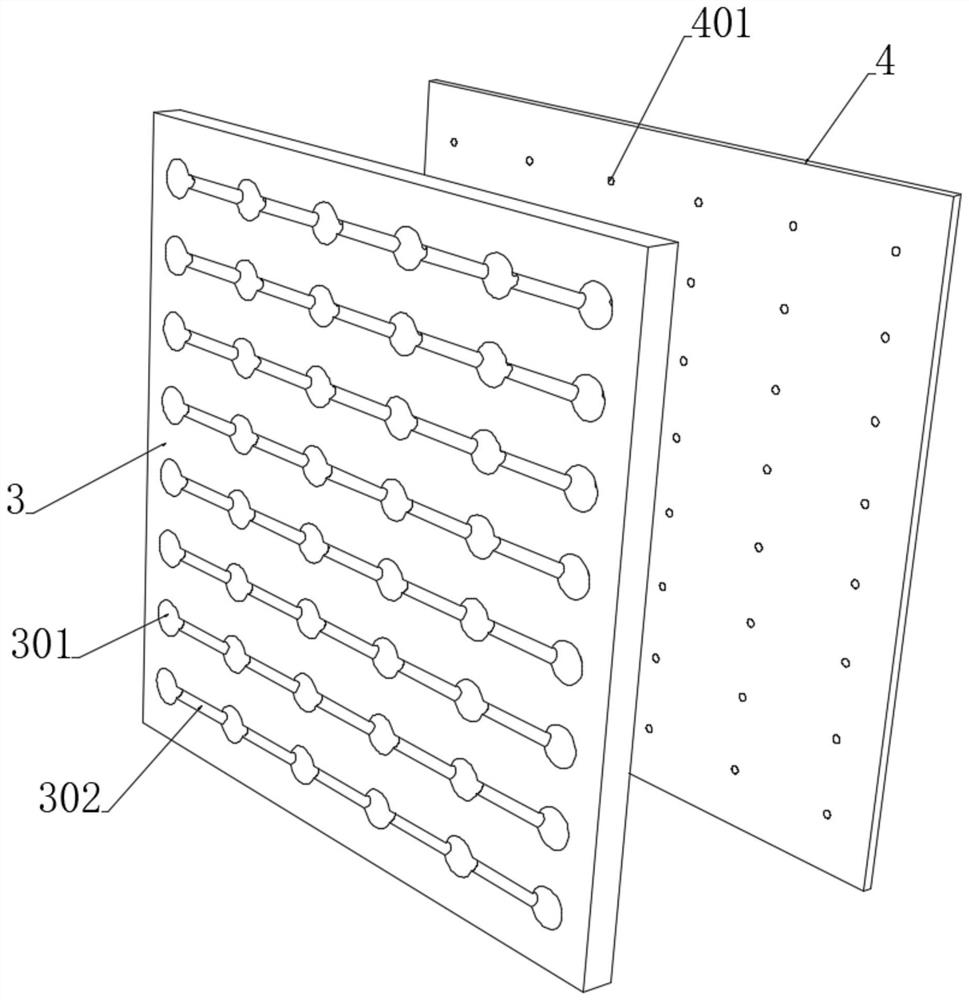

[0038] see Figure 1-3 , a heat-resistant and fire-resistant building fire-fighting floor, including an inner base plate 1, a flame-retardant layer and an outer decorative plate 4 distributed sequentially from the inside to the outside, the flame-retardant layer includes an inner heat-insulating layer 2 and an outer fire-proof layer 3 distributed inside and outside, The exterior decorative panel 4 includes a fireproof decorative layer located on the outside, and the interior of the fireproof decorative layer is provided with a mineral glass magnesium fireproof material filling layer, which plays a good decorative role on the one hand, and can resist high temperature on the other hand, and is suitable as the exterior decoration of the fire floor. The inner base plate 1 is a polymer mortar board connected to the inner end of the inner heat insulation layer 2, and a glass fiber mesh cloth is arranged between the polymer mortar board and the inner heat insulation layer 2, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com