A kind of geotechnical engineering fault fissure rock mass grouting equipment

A technology of fractured rock mass and geotechnical engineering, applied in the direction of infrastructure engineering, construction, sheet pile wall, etc. The effect of strengthening strength and reducing pulp consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

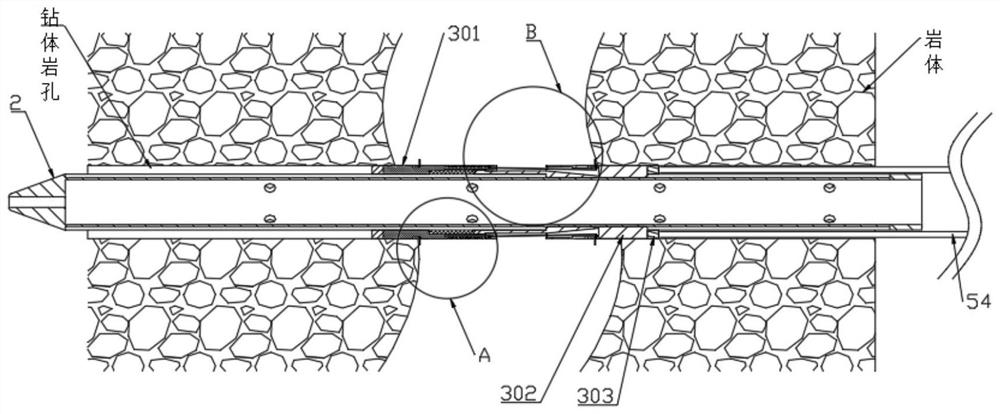

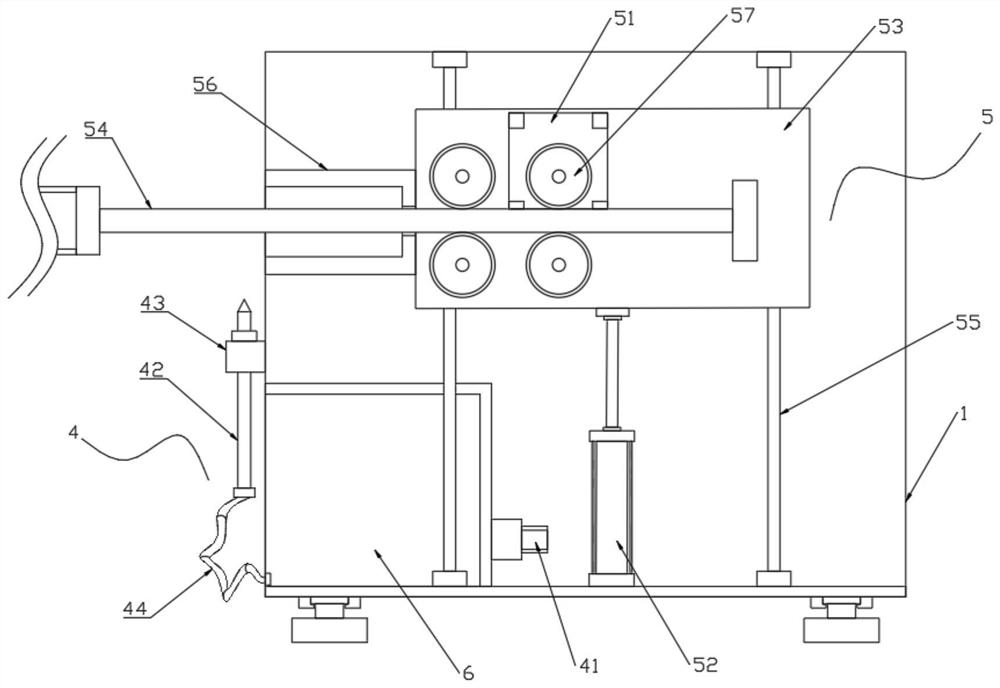

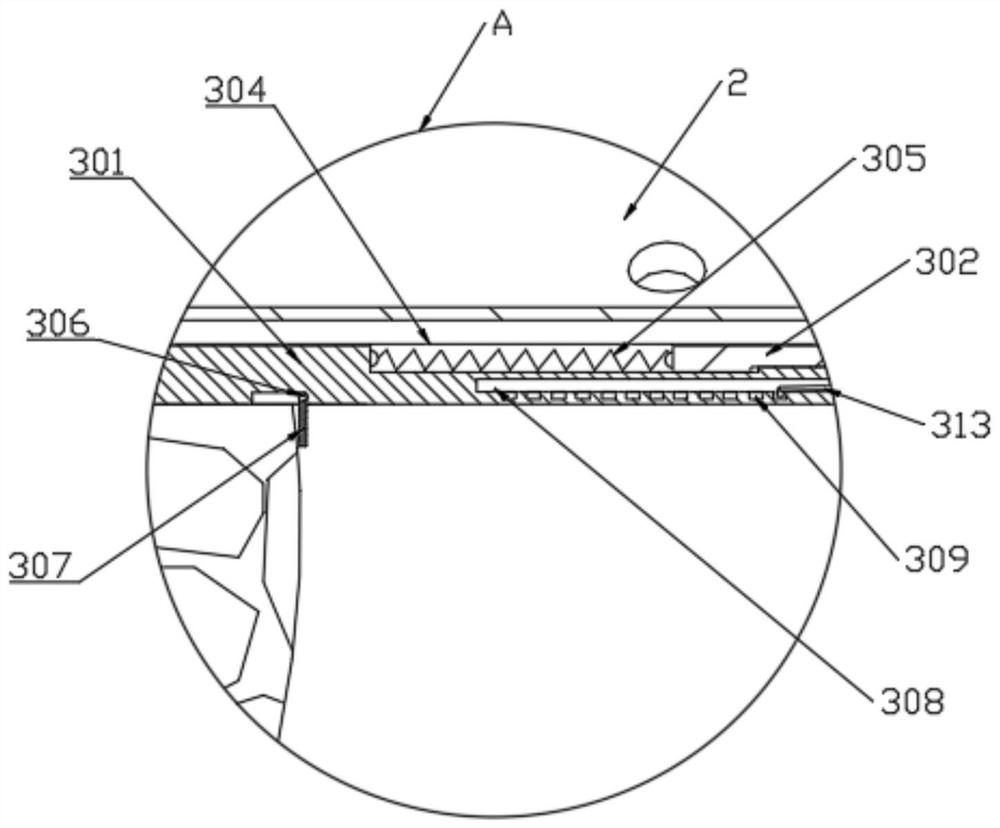

[0024] like Figure 1 to Figure 6 As shown, a geotechnical engineering fault fissure rock mass grouting equipment includes a trolley 1, an anchor rod 2, a partition 3, a grouting mechanism 4 and a jacking mechanism 5. The interior of the trolley 1 is provided with a slurry storage chamber 6. The grouting mechanism 4 is installed on the slurry chamber 6 and is used to inject mortar into the drilling hole of the rock mass. In terms of application height, the partition part 3 is sleeved on the bolt 2 and used to prevent the slurry from spreading in the crack of the rock fault.

[0025] In this embodiment, the reinforcing slurry used is fluidized mortar, and a quick-setting agent and a micro-expansion agent are added inside.

[0026] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com