System combining bottom seepage drainage and flood drainage facilities

A combination of technology and facilities, applied in the direction of waterway system, sewer system, sewage discharge, etc., can solve the problems that cannot be repaired, and achieve the effect of accelerating drainage consolidation, shortening the time of seepage discharge, and improving anti-sliding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

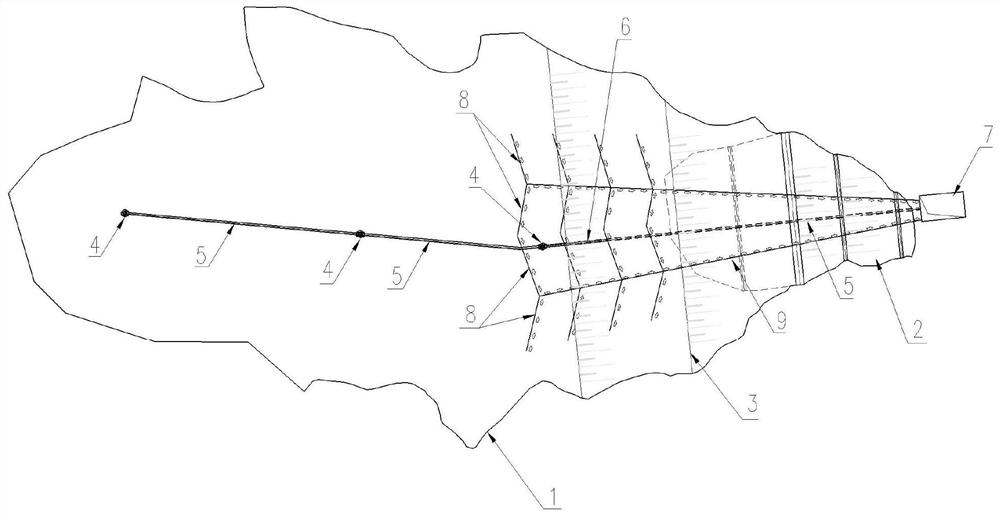

[0054] A system that combines bottom seepage and flood drainage facilities, such as Figure 4-9 Shown, with reference to comparative example, the difference with comparative example is as follows:

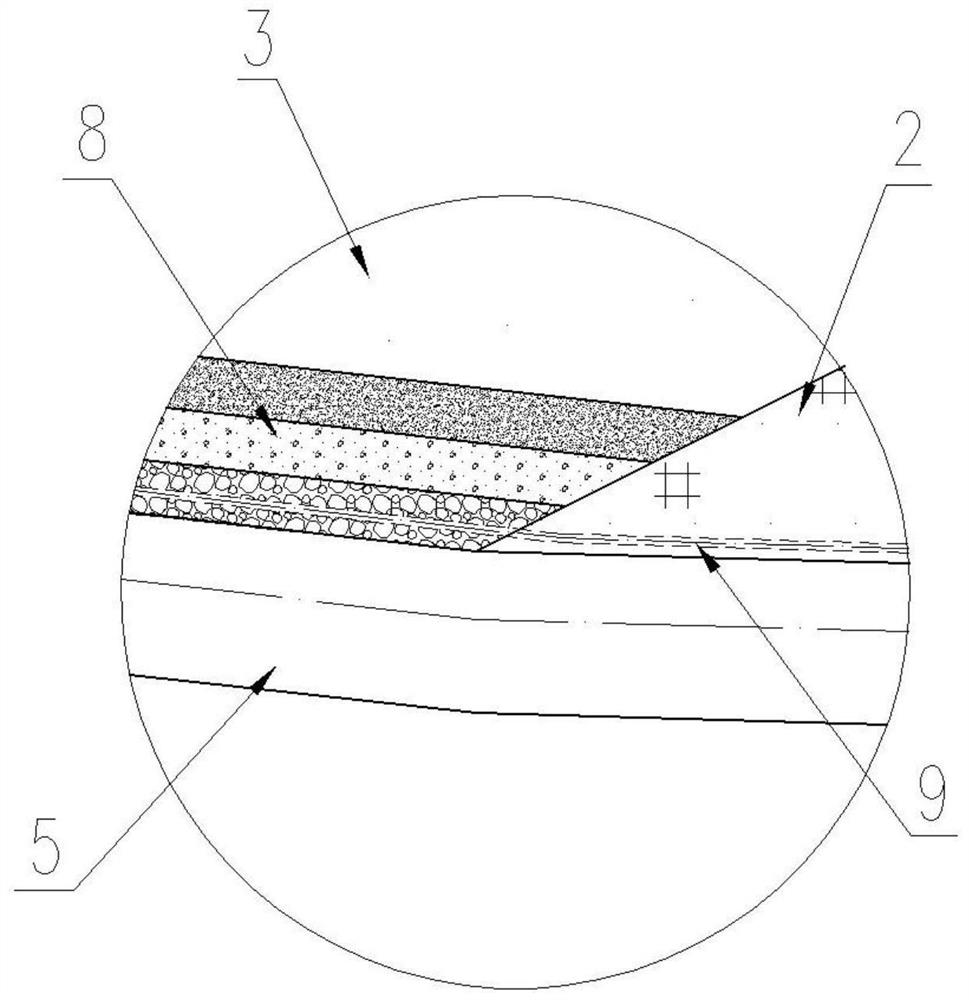

[0055] Seepage drainage facilities include seepage collection facility 8 and seepage guide pipe 9.1; described seepage collection facility 8 includes seepage collection pipe 8.1; described seepage collection pipe communicates with flood discharge facilities through seepage guide pipe 9.1, and seepage collection facility 8 is collected The seepage water is diverted to the flood drainage facilities.

[0056] The connection pattern between the seepage collection facility 8 and the drainage culvert pipe 5 and the drainage chute 6 is a fishbone arrangement; the connection pattern between the seepage collection facility 8 and the drainage well 4 is a radial arrangement.

[0057] The seepage collection pipe 8.1 is a perforated seepage collection pipe; the seepage collection facility 8 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com