Plant fiber-based controllable permeable material and preparation method thereof

A technology of plant fibers and water-permeable materials, applied in botany equipment and methods, fiber raw material processing, non-fibrous pulp addition, etc., can solve the problems of non-degradable water storage containers, uncontrollable irrigation rates, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

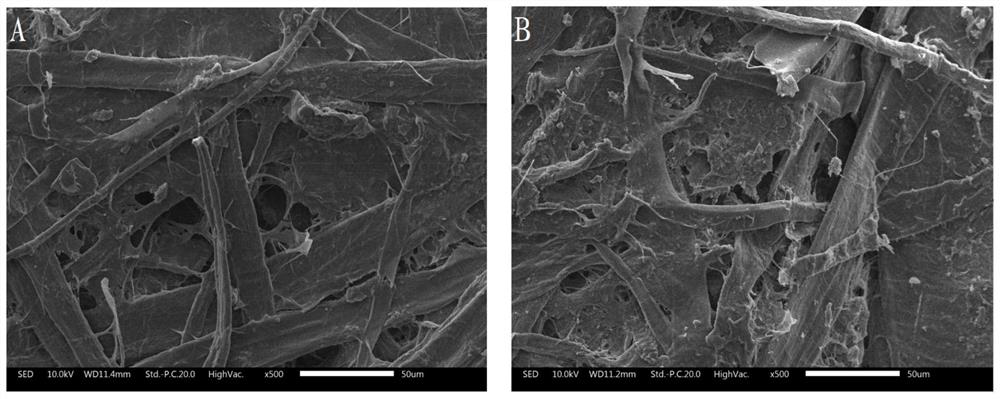

[0073] The embodiment of this application provides the first plant fiber-based controllable water-permeable material, and the specific preparation method is as follows:

[0074] Mix waste paper fiber slurry, polyamide polyamine-epichlorohydrin resin, carboxymethyl cellulose and styrene-acrylic acid ester, form it by wet method, and then dry it by hot pressing to obtain a controllable plant fiber base. Permeable material, labeled Sample 1.

[0075] Wherein, the addition of polyamide polyamine-epichlorohydrin resin is 1.5% of the dry pulp quality of waste paper fiber slurry; the addition of styrene-acrylate is 1.5% of the dry pulp quality of waste paper fiber slurry. 5%; the added amount of carboxymethyl cellulose is 0.5% of the weight of the dry pulp of waste paper fiber pulp. The beating degree of the waste paper fiber slurry is 30°SR, the drying method is hot-press drying, the drying temperature is 180°C, and the drying time is 20 minutes.

Embodiment 2

[0077] The embodiment of this application provides the second plant fiber-based controllable water-permeable material, and the specific preparation method is as follows:

[0078] Take agricultural straw fiber slurry, alkyl ketene dimer, styrene-acrylic ester and polyamide polyamine-epichlorohydrin resin, mix them, use wet papermaking to form paper, and then dry in an oven to obtain plant fiber base The controllable water-permeable material is marked as sample 2.

[0079] Wherein, the addition amount of polyamide polyamine-epichlorohydrin resin is 2% of the dry pulp mass of agricultural straw fiber slurry; the addition amount of alkyl ketene dimer is the dry pulp of agricultural straw fiber slurry 0.5% of the mass of the material; the addition of styrene-acrylate is 4% of the dry mass of the agricultural straw fiber slurry. The beating degree of the agricultural straw fiber slurry is 40°SR, the drying method is oven drying, the drying temperature is 160°C, and the drying time ...

Embodiment 3

[0081] The embodiment of this application provides the third plant fiber-based controllable water-permeable material, the specific preparation method is as follows:

[0082] The waste paper fiber slurry, urea-formaldehyde resin, cationic polyacrylamide and styrene-acrylate were mixed, formed by wet method, and then dried by hot pressing to obtain a plant fiber-based controllable water-permeable material, marked as sample 3.

[0083] Among them, the addition of urea-formaldehyde resin is 3% of the dry pulp mass of waste paper fiber pulp; the addition of styrene-acrylate is 15% of the dry pulp mass of waste paper fiber pulp; cationic polypropylene The amount of amide added is 1% of the dry pulp mass of the waste paper fiber pulp. The beating degree of the waste paper fiber slurry is 25°SR, the drying method is hot-press drying, the drying temperature is 140°C, and the drying time is 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com