Annealing device and working method thereof

An annealing device and annealing chamber technology, applied in chemical instruments and methods, crystal growth, diffusion/doping, etc., can solve problems such as temperature unevenness, and achieve the effects of improving uniformity, avoiding adverse effects, and avoiding insufficient annealing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

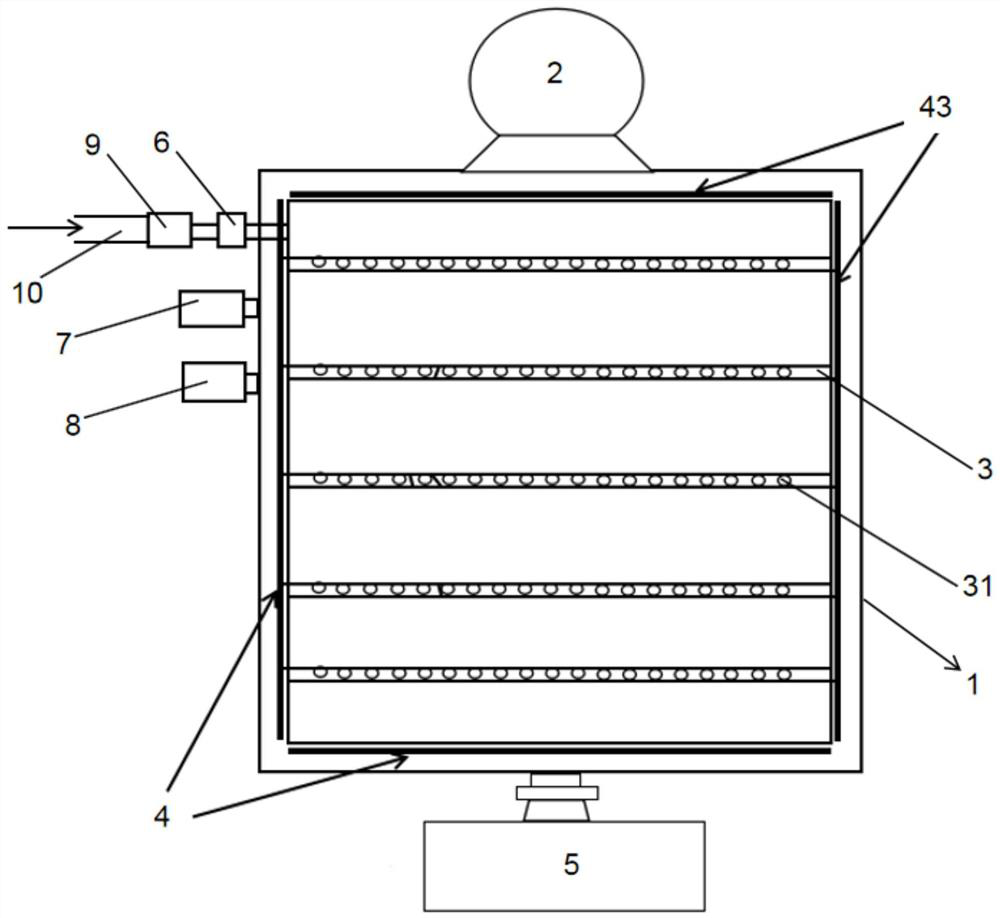

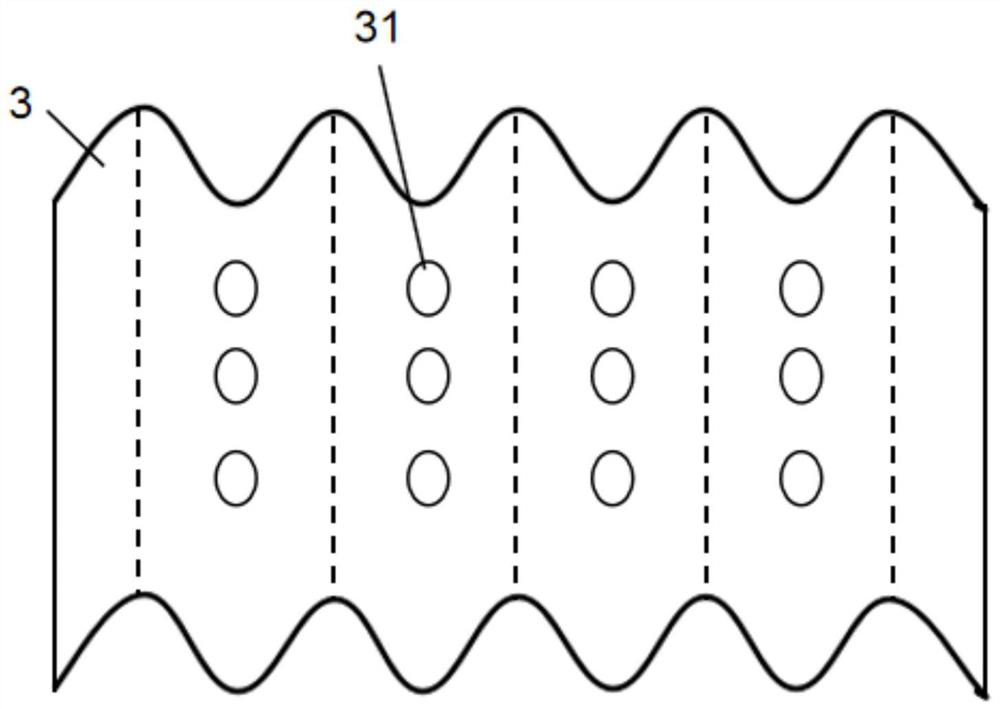

[0035] Such as figure 1 As shown, this embodiment provides an annealing device, including: an annealing chamber main body 1; an air circulation fan 2 arranged outside the annealing chamber main body 1, the air circulation fan 2 includes a rotating part and is arranged on the rotating part The outer shell is in sealing communication with the annealing chamber main body 1 .

[0036] In the above-mentioned annealing device, during the annealing process, the rotating member rotates to drive the airflow in the annealing chamber main body 1, so that heat exchange occurs at different positions in the annealing chamber main body 1, thereby improving the temperature of the annealing chamber main body 1. The uniformity of temperature at different positions avoids insufficient annealing degree of the parts to be annealed due to the low temperature in some areas of the annealing chamber main body 1, and avoids adverse effects on the performance of the semiconductor chip; at the same time,...

Embodiment 2

[0058] This embodiment provides a working method of an annealing device, using the annealing device provided in Embodiment 1, the working method of the annealing device includes the step of turning on the air circulation fan 2, and rotating the rotating member to disturb the housing and The airflow in the main body 1 of the annealing chamber. Through the above working method, the heat at different positions in the annealing chamber main body 1 is exchanged, thereby improving the uniformity of temperature at different positions in the annealing chamber main body 1, and avoiding the low temperature in some areas of the annealing chamber main body 1. As a result, the annealing degree of the parts to be annealed in this region is insufficient, and the performance of the semiconductor chip is avoided from being adversely affected.

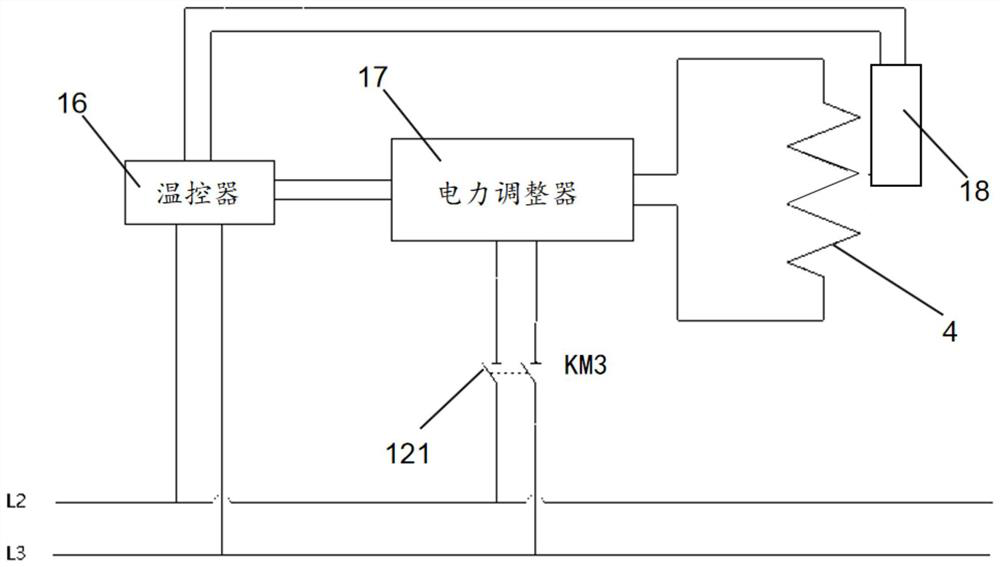

[0059] In this embodiment, the working method of the annealing device further includes: the temperature sensor 18 obtains the actual temperature inform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com