Rubber pressing and packaging treatment device for rubber production

A bag processing and bag device technology, which is applied in the field of rubber press bag processing devices, can solve the problems of polluted hydraulic system performance, influence, and high level of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

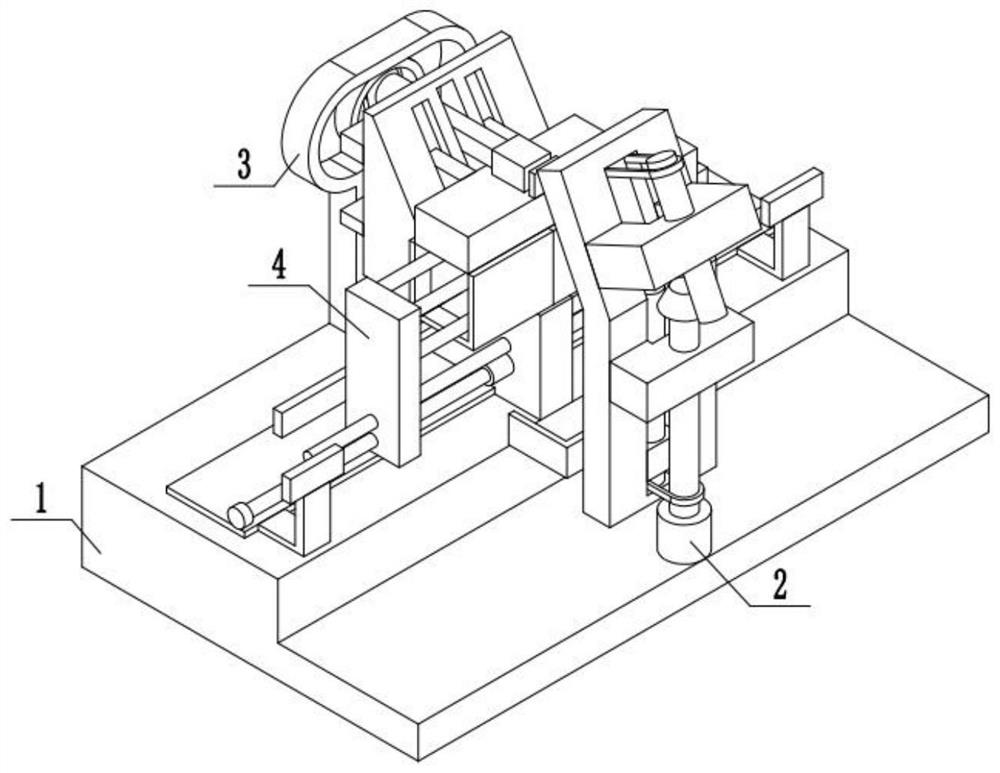

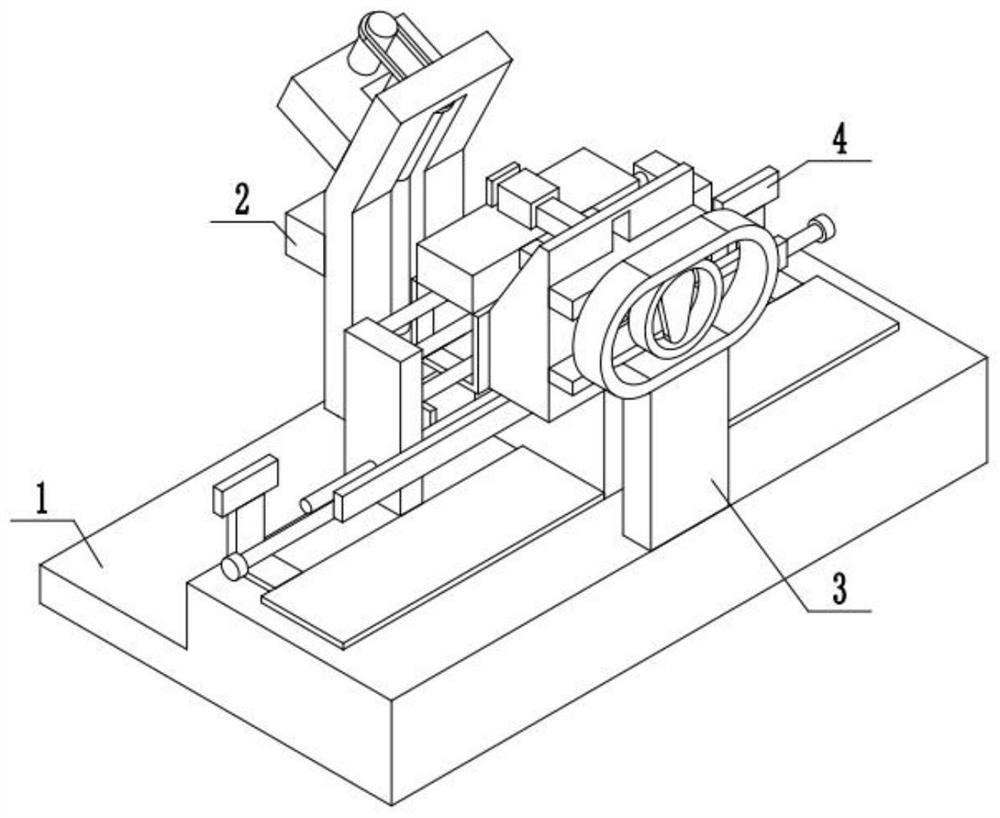

[0037] Combine below figure 1 , 2 Description of this embodiment, a rubber pressing device for rubber production, including a stepped bottom plate 1, a rubber adding device 2, a driving device 3 and a rubber pressing device 4, the rubber adding device 2 is fixedly installed on the bottom of the stepped bottom plate 1 Above, the top of the stepped bottom plate 1 is fixedly equipped with a driving device 3 , the top of the stepped bottom plate 1 is fixedly installed with a rubber pressing device 4 , and the driving device 3 is equipped with a rubber pressing device 4 .

specific Embodiment approach 2

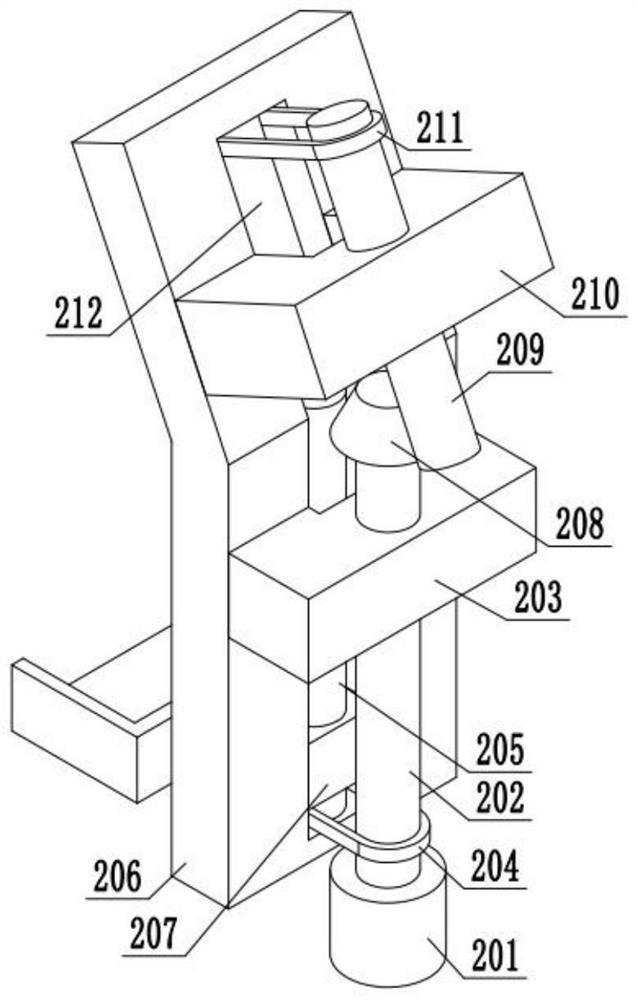

[0039] Combine below image 3 , 4 Describe this embodiment, this embodiment will further explain the first embodiment, the rubber adding device 2 includes a power motor A201, a transmission shaft 202, a fixed frame A203, a transmission belt A204, a driving screw A205, a guide bracket 206, and a rubber storage box 207, driving bevel gear 208, toothed transmission shaft 209, fixed frame B210, transmission belt B211, driving screw rod B212, power motor A201 is fixedly installed above the ladder base plate 1, and the output end of power motor A201 is equipped with transmission shaft 202, transmission shaft 202 is movably installed on the fixed frame A203, and the fixed frame A203 is fixedly installed on the guide curved frame 206. The transmission shaft 202 is connected with the driving screw A205 through the transmission belt A204, and the lower part of the driving screw A205 is movably installed on the guide curved frame 206 to drive the screw rod A205. A rubber storage box 207...

specific Embodiment approach 3

[0041] Combine below Figure 5 , 6 Illustrate this embodiment, and this embodiment will further explain Embodiment 1. The described driving device 3 includes a limiting frame fixing plate 301, an annular limiting frame 302, a driving ring sleeve 303, a cam 304, a power motor B305, and the output of the power motor B305 A cam 304 is installed at the end, and the cam 304 is in contact with the driving circular sleeve 303, and the driving circular sleeve 303 is slidably installed in the annular limiting frame 302, and the annular limiting frame 302 is fixedly installed on the limiting frame fixing plate 301, and the limiting frame fixing plate 301 is fixedly installed On the top of the ladder bottom plate 1, start the power motor B305, the power motor B305 drives the cam 304 to rotate, the cam 304 rotates and drives the circular sleeve 303 to slide on the annular limit frame 302, when the small round end of the driving cam 304 and the top of the driving circular sleeve 303 Or wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com