Polyimide film hot air drying equipment and air drying method thereof

A polyimide film, hot air drying technology, applied in the direction of coating, etc., can solve the problem of inability to detect the elasticity degree of polyimide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

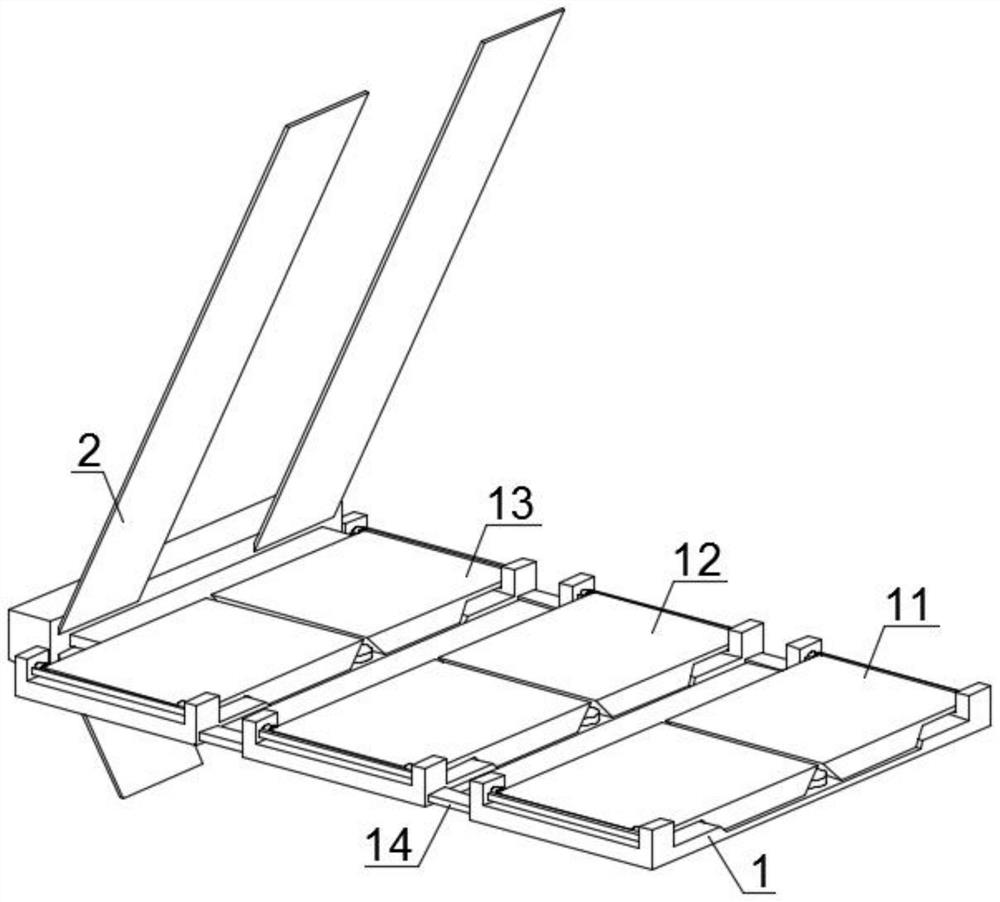

[0032] Such as figure 1 , 2 , 4 and 5, the polyimide film hot air drying equipment includes a hot air drying mechanism 1 and an adjustment mechanism 2, the side end of the hot air drying mechanism 1 is equipped with an adjustment mechanism 2, and the hot air drying mechanism 1 includes a first material holding mechanism 11 , the second material-filling mechanism 12, the 3rd material-filling mechanism 13 and the ventilation mechanism 14, the first material-filling mechanism 11, the second material-filling mechanism 12 and the 3rd material-filling mechanism 13 are flexibly connected by the ventilation mechanism 14, the third The side end of the material holding mechanism 13 is equipped with an adjustment mechanism 2, and the adjustment mechanism 2 includes a placement box 21, a connecting horizontal plate 22, a bottom support inclined plate 23 and a movable slat 24, and the side end of the placement box 21 is equipped with a connecting horizontal plate 22, The lower end of the ...

Embodiment 2

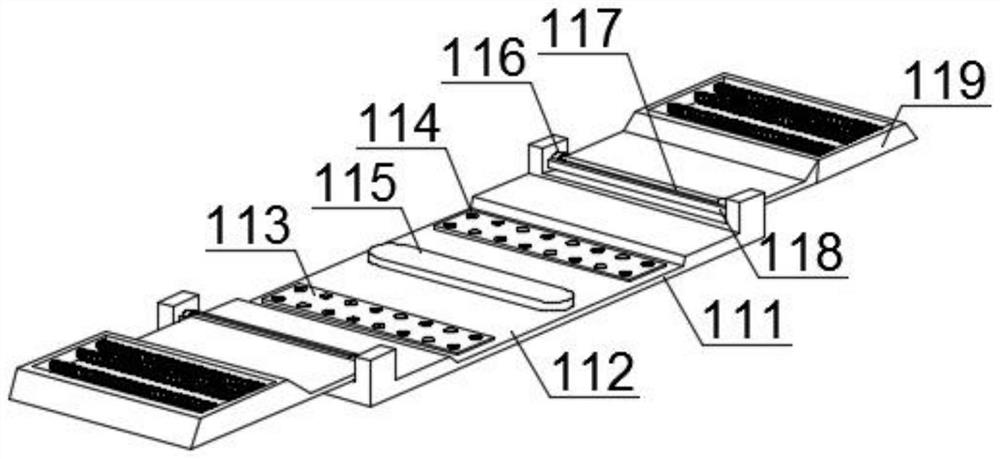

[0034] Such as figure 2 and 4As shown, the polyimide film hot air drying equipment, the first material holding mechanism 11 includes a material holding frame plate 111, an inner slot 112, a contact inner plate 113, an arrangement hole 114 and a force unloading middle block 115, and a material holding frame plate 111 The upper end of the inner slot 112 is provided with an inner slot 112, the two sides of the inner cavity of the inner slot 112 are provided with a contact inner plate 113, and the two sides of the contact inner plate 113 are arranged with arrangement holes 114, and the contact inner plate 113 is installed. Block 115, unloading middle block 115 is a member made of a synthetic rubber material, the first material holding mechanism 11 also includes an edge opening 116, an embedded roller 117, an installation horizontal box 118 and a pressing movable plate 119, and the edge opening 116 The two walls of the inner cavity of the inner cavity are provided with embedded r...

Embodiment 3

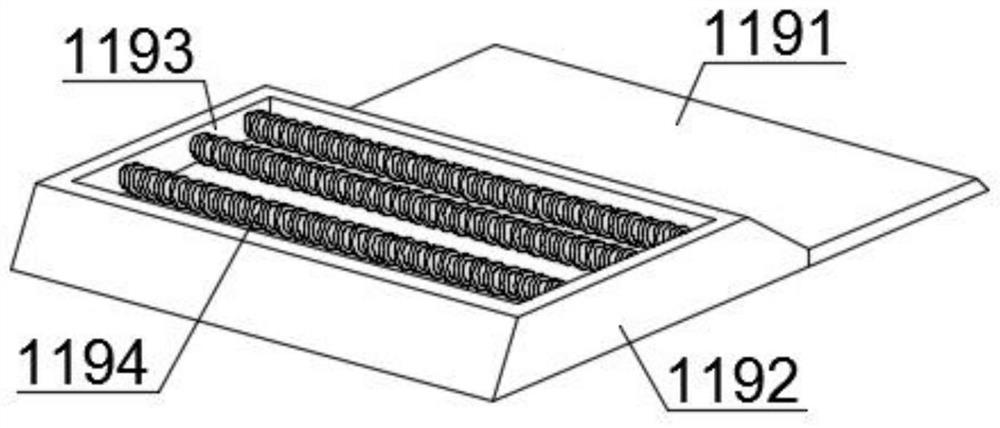

[0036] Such as figure 2 and 3 As shown, the hot air drying equipment for polyimide film, the pressing movable plate 119 includes a connecting plate body 1191, an installation box 1192, an inner opening 1193 and a screw shaft 1194, and the side end of the connecting plate body 1191 is equipped with an installation box 1192, an installation box 1192 There is an inner opening 1193 at the bottom of the inner opening 1193, and the inner cavity of the inner opening 1193 is arranged with a screw shaft 1194, and the pressing movable plate 119 is rotated 180 degrees to the outer end with the embedded roller 117 as a fulcrum, and the polyimide film is flattened into the The inner cavity of the inner groove 112 contacts the inner plate 113 to support the bottom end of the polyimide film, and presses the movable plate 119 to buffer the pressure through the unloading middle block 115, so that the polyimide film can be laid flat In the inner cavity of the groove 112, the external motor dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com