Precise hot forming method for metal forgings with nearly semi-elliptical thin web and large rib spacing

A semi-elliptical, thin-web technology, applied in the field of warm forging, can solve problems such as rib folding, partial filling of metal components, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

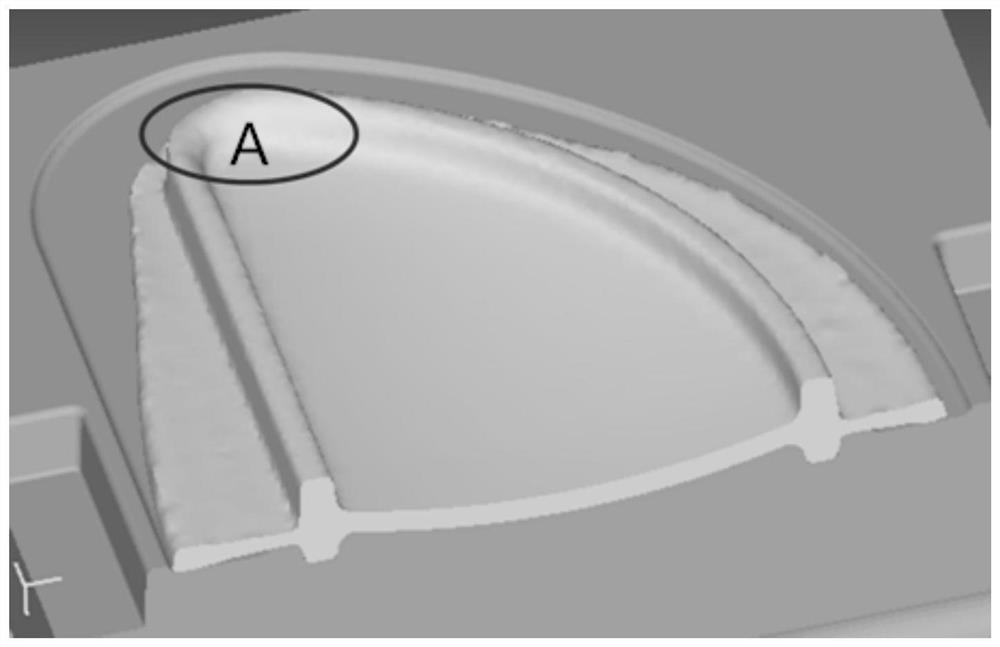

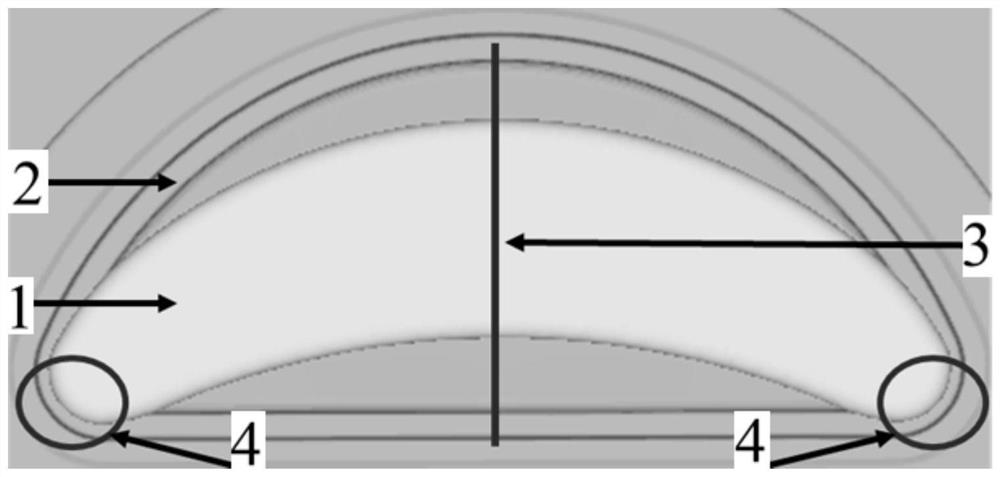

[0037] Specific Embodiment 1: A method for precision hot forming of metal forgings with a nearly semi-elliptical thin web and large rib spacing described in this embodiment. The metal forging with a nearly semi-elliptical thin web and large rib spacing is It is prepared from a crescent-shaped blank, and the specific preparation method is carried out according to the following steps:

[0038] 1. Preparation of preform:

[0039] Machining thick metal plates of equal thickness into crescent-shaped blanks to obtain preforms;

[0040] The shape of the crescent-shaped blank is different from that of the metal forging; the metal forging is a metal forging with a nearly semi-elliptical thin web and large rib spacing;

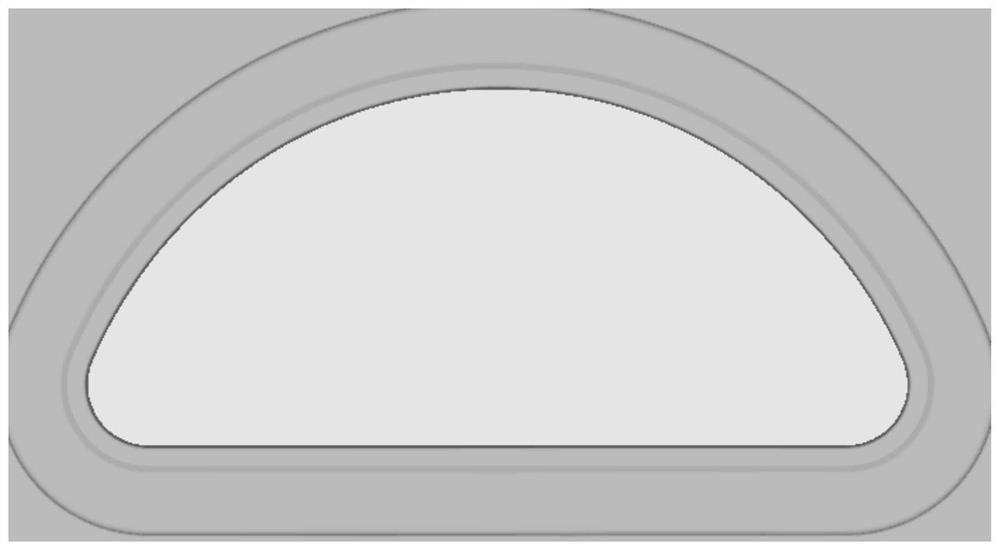

[0041] The web of the metal forging is a nearly semi-elliptical shape symmetrical to the left and right along the central axis, and the left and right ends of the nearly semi-elliptical shape are arc-shaped. The webs have the same shape; the aspect ratio of the web is...

specific Embodiment approach 2

[0059] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the material of the equal-thickness metal plate described in step 1 is aluminum alloy; the upper and lower surface contour edges of the crescent-shaped blank described in Step 1 are reversed Fillet processing, the radius of the fillet obtained by the rounding treatment is 1 / 6 to 1 / 3 of the thickness of the preform. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0060] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the aluminum alloy is a 2XXX series aluminum-lithium alloy. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com