Top cover sorting device for food processing

A technology of a food processing and sorting device, applied in the field of food processing, can solve problems such as top cover leakage, top cover falling, food safety problems, etc., and achieve the effect of prolonging the service life and avoiding folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

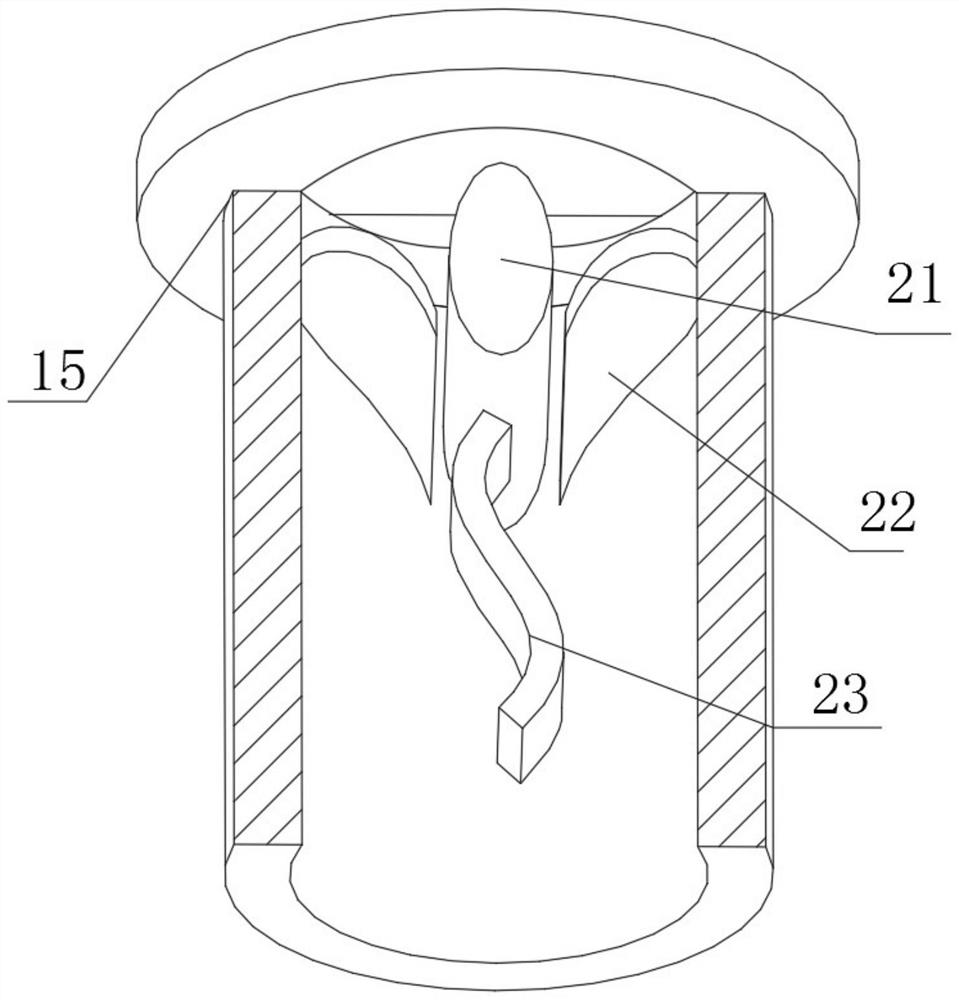

[0032] refer to Figure 1-5 , a top cover sorting device for food processing, comprising an operating table 18 and a top cover 10, a film 24 is arranged inside the top cover 10, a partition 3 is fixed on the operation table 18, and the top outer wall of the partition 3 is fixed with The clapboard 3, the top outer wall of the electric telescopic rod 4 is fixed with a wing plate 5, the bottom outer wall of the wing plate 5 is provided with a plurality of equidistantly distributed glands 8, and the top outer wall of the gland 8 is provided with a sealing cover 7, the pressure The bottom outer wall of the cover 8 is snapped with a sealing ring 20, the top outer wall of the console 18 is provided with a transport trough, and the bottom inner wall of the transport trough is slidingly provided with a conveyor belt 16, and the outer wall of one side of the console 18 is fixed with a gas detector 2 , and the top outer wall of the gas detector 2 is provided with a plurality of equidista...

Embodiment 2

[0039] refer to Figure 6 , a top cover sorting device for food processing. Compared with Embodiment 1, the outer wall of the top of the gas injection valve 1 is provided with a protective sleeve 26 in this embodiment.

[0040] During use, the conveyor belt 16 is powered by the power mechanism, the electric telescopic rod 4 moves, and the wing plate 5 drives the gland 8 to press down to the top of the top cover 10 clamped in the jaws 28, and the seal ring 20 and the gland 8 After that, the gas injection valve 1 acts, and the inside of the gas detector 2 generates an appropriate air pressure so that the air pressure in the inlet pipe 19 is greater than the air pressure outside the inlet pipe 19. At this time, the gas detector 2 detects the gas pressure in the inlet pipe 19 At the same time, the volume of the gas charged into the gas detector 2 through the gas guide tube 13 is detected. If the air pressure in the intake pipe 19 drops significantly during the pressure stabilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com